A kind of iron series element microporous molecular sieve and its preparation method and application

A microporous molecular sieve, iron-based element technology, applied in chemical instruments and methods, water/sewage treatment equipment, biological water/sewage treatment, etc., can solve the problems of waste liquid polluting the environment, long synthesis time, small specific surface area, etc. Achieve the effect of low price, saving money, and low hydrogen evolution overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

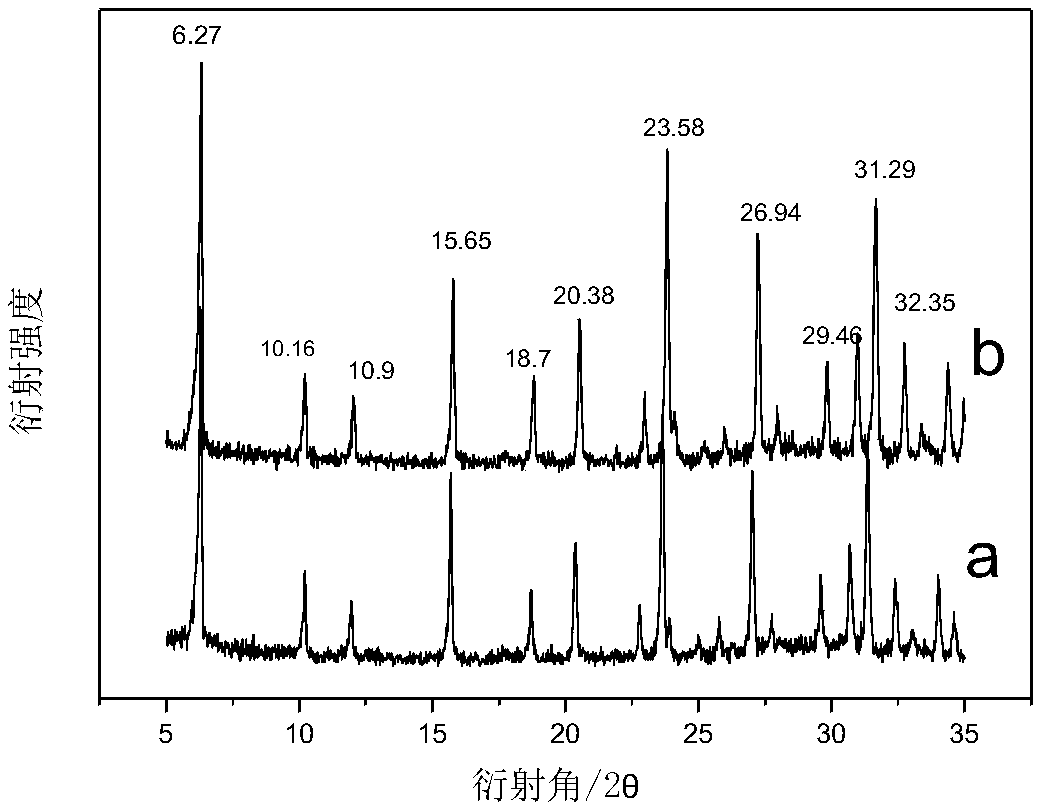

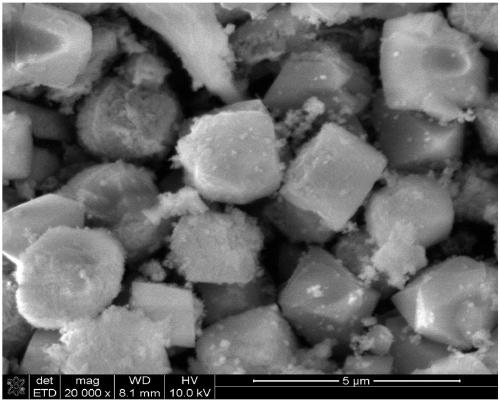

[0044] A microporous molecular sieve of iron series elements in this embodiment is a microporous molecular sieve containing nickel, and its chemical molecular formula is:

[0045] Na 67.56 [Ni 14.64 Al 38.32 Si 139.05 o 384 ]·264H 2 O,

[0046] 1. Synthesis of nickel-containing microporous molecular sieves

[0047] The preparation method of the above-mentioned nickel-containing microporous molecular sieve comprises the following steps:

[0048] 1) Synthesis of directing agent

[0049] ① Preparation of directing agent gel

[0050] Take deionized water, sodium hydroxide, sodium metaaluminate, and 30% silica sol in a molar ratio of 129:10.16:1:5.86;

[0051] Add deionized water, sodium hydroxide and sodium metaaluminate to the polytetrafluoroethylene reaction vessel in sequence, then add the silica sol drop by drop at a speed of 2 drops / second, and stir at a constant speed on the stirrer to fully mix the raw materials. After stirring for 30min, the mixture in the polyte...

Embodiment 2

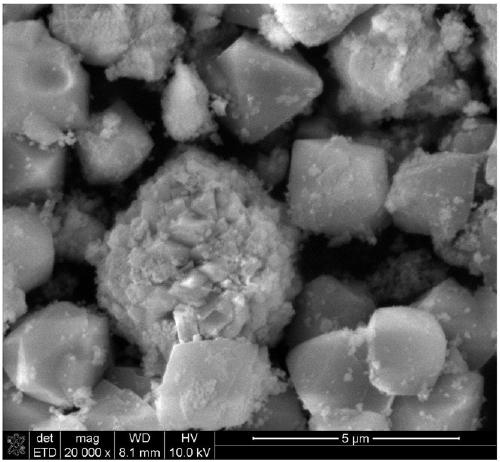

[0088] A microporous molecular sieve of iron series elements in this embodiment is a microporous molecular sieve containing cobalt, and its chemical molecular formula is:

[0089] Na 67.56 [Co 14.64 al 38.32 Si 139.05 o 384 ]·264H 2 O,

[0090] 1. Synthesis of cobalt-containing microporous molecular sieves

[0091] The preparation method of the above-mentioned cobalt-containing microporous molecular sieve comprises the following steps:

[0092] 1) Synthesis of directing agent

[0093] ① Preparation of directing agent gel

[0094] Take deionized water, sodium hydroxide, sodium metaaluminate, and 30% silica sol in a molar ratio of 129:10.16:1:5.86;

[0095] Add deionized water, sodium hydroxide and sodium metaaluminate to the polytetrafluoroethylene reactor in turn, then add the silica sol drop by drop at a speed of 2 drops / second, and stir at a constant speed on the stirrer to fully mix the raw materials. After stirring for 30min, the mixture in the polytetrafluoroeth...

Embodiment 3

[0124] A microporous molecular sieve of iron series elements in this embodiment is a microporous molecular sieve containing nickel, and its chemical molecular formula is:

[0125] Na 67.56 [Ni 14.64 al 38.32 Si 139.05 o 384 ]·264H 2 O,

[0126] 1. Synthesis of nickel-containing microporous molecular sieves

[0127] The preparation method of the above-mentioned nickel-containing microporous molecular sieve comprises the following steps:

[0128] 1) Synthesis of directing agent

[0129]① Preparation of directing agent gel

[0130] Take deionized water, sodium hydroxide, sodium metaaluminate, and 30% silica sol in a molar ratio of 129:10.16:1:5.86;

[0131] Add deionized water, sodium hydroxide and sodium metaaluminate to the polytetrafluoroethylene reactor in turn, then add the silica sol drop by drop at a speed of 2 drops / second, and stir at a constant speed on the stirrer to fully mix the raw materials. After stirring for 30min, the mixture in the polytetrafluoroethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com