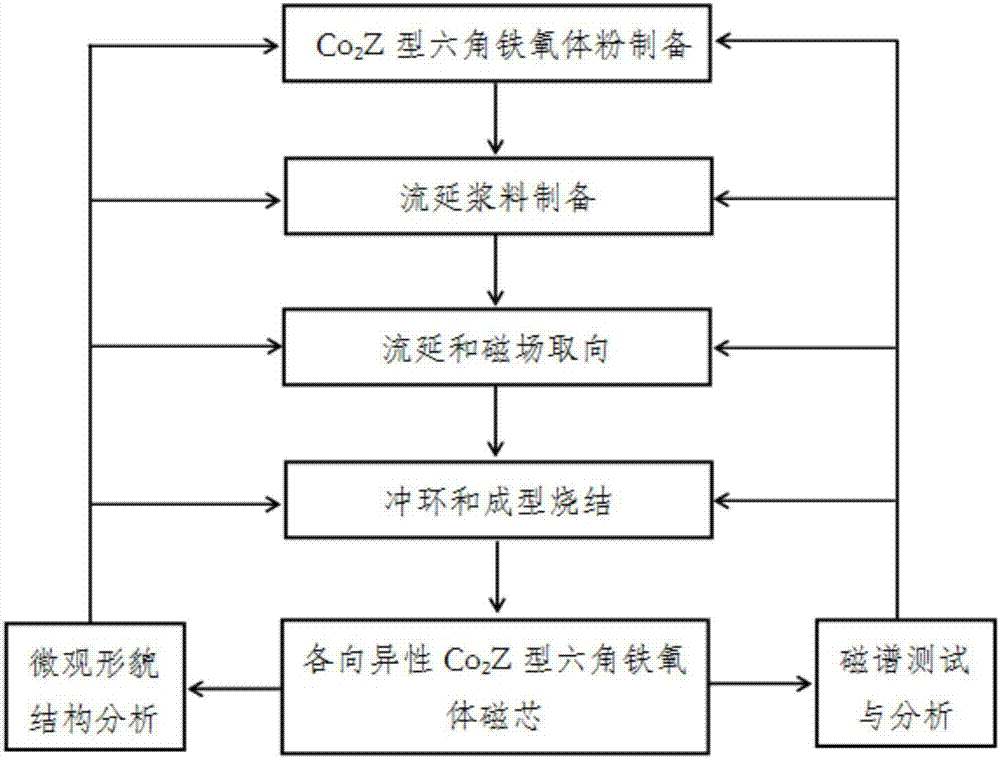

Anisotropic Co2Z type hexagonal ferrite magnetic core, and preparation method thereof

A hexagonal ferrite, anisotropic technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of low operating frequency, restricting the development and application of ferrite magnetic powder cores, etc., to achieve high production efficiency, Achieve miniaturization and high quality factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to Co 2 The structural formula of Z-type ferrite is 3BaO 2CoO 12Fe 2 o 3 Ratio Weighing Raw BaCO 3 、Co 2 o 3 , Fe 2 o 3 , adding ball milling medium zirconia balls and performing ball milling and mixing for 5 hours, drying, pulverizing and sieving the obtained materials. Pre-burn the sieved material at 1300°C for 2 hours, then add the sintering aid Bi to the pre-calcined material 2 o 3 , and perform secondary ball milling, where Bi 2 o 3 The addition amount is 1% of the weight of the material after pre-burning, and the ball milling time is 2 hours.

[0026] Get 100g of the material after secondary ball milling and add 50g of PVB solution with a concentration of 40wt% to it, after mixing evenly, add plasticizer dimethyl phthalate 0.5g and dispersant polyethylene glycol octylphenyl Ether 2g, prepared into cast slurry.

[0027] The casting slurry was cast on the PET film by a casting process, and after being horizontally oriented in a magnetic field, ...

Embodiment 2

[0031] According to Co 2 The structural formula of Z-type ferrite is 3BaO 2CoO 12Fe 2 o 3 Ratio Weighing Raw BaCO 3 、Co 2 o 3 , Fe 2 o 3 , adding ball milling medium zirconia balls and performing ball milling and mixing for 5.5 hours, drying, pulverizing and sieving the obtained materials. Pre-burn the sieved material at 1250°C for 2.5 hours, then add the sintering aid Bi to the pre-calcined material 2 o 3 , and perform secondary ball milling, where Bi 2 o 3 The addition amount is 3% of the weight of the material after pre-burning, and the ball milling time is 3 hours.

[0032] Get 100g of the material after secondary ball milling and add 45g of PVB solution with a concentration of 45wt% to it, after mixing evenly, add plasticizer dimethyl phthalate 0.25g and dispersant polyethylene glycol octylphenyl Ether 1.5g, prepared into cast slurry.

[0033] The cast slurry was cast on the PET film by a cast process, and after being horizontally oriented in a magnetic field,...

Embodiment 3

[0037] According to Co 2 The structural formula of Z-type ferrite is 3BaO 2CoO 12Fe 2 o 3 Ratio Weighing Raw BaCO 3 、Co 2 o 3 , Fe 2 o 3 , adding ball milling medium zirconia balls and performing ball milling and mixing for 6 hours, drying, pulverizing and sieving the obtained materials. Pre-burn the sieved material at 1200°C for 3 hours, then add the sintering aid Bi to the pre-calcined material 2 o 3 , and perform secondary ball milling, where Bi 2 o 3 The addition amount is 2% of the weight of the material after pre-burning, and the ball milling time is 4 hours.

[0038] Get 100g of the material after secondary ball milling and add 40g of PVB solution with a concentration of 50wt% to it, after mixing evenly, add plasticizer dimethyl phthalate 0.2g and dispersant polyethylene glycol octylphenyl Ether 1g, prepared into cast slurry.

[0039] The cast slurry was cast on the PET film by a cast process, and after being horizontally oriented in a magnetic field, it was d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com