A kind of iron-based amorphous alloy with low stress sensitivity and preparation method thereof

An iron-based amorphous alloy and strain coefficient technology, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the deterioration of transformer core performance without considering the soft magnetic properties of materials, the lack of understanding of stress relief of amorphous strips, and the results One-sided and other problems, to achieve the effect of strong resistance to sudden short circuit, low stress sensitivity, and high banding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

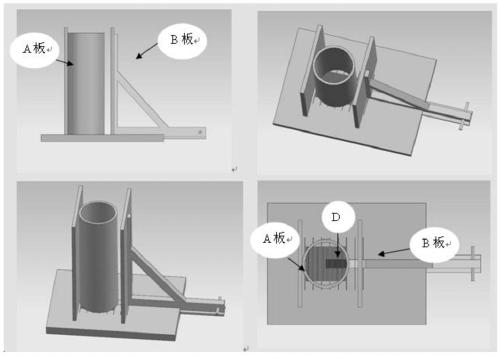

[0044] The present application also provides a method for preparing an iron-based amorphous alloy strip as shown in formula (I), comprising:

[0045] Dosing of elements according to the atomic percentage of the formula (I), smelting the raw materials after the batching, raising the temperature of the smelted melt and then performing single-roll rapid quenching to obtain an iron-based amorphous alloy strip;

[0046] Fe a B b Si c (I);

[0047] Wherein, a, b and c respectively represent the atomic percentage of the corresponding components; 79.5≤a≤82.5, 11.0≤b≤13.5, 6.5≤c≤8.5, a+b+c=100.

[0048] In the process of preparing the iron-based amorphous alloy strip, the present application adopts conventional technical means in the field to prepare the iron-based amorphous alloy strip with the specific composition of the present application. The batching and smelting process in the above-mentioned preparation method is a process well known to those skilled in the art, and this a...

Embodiment

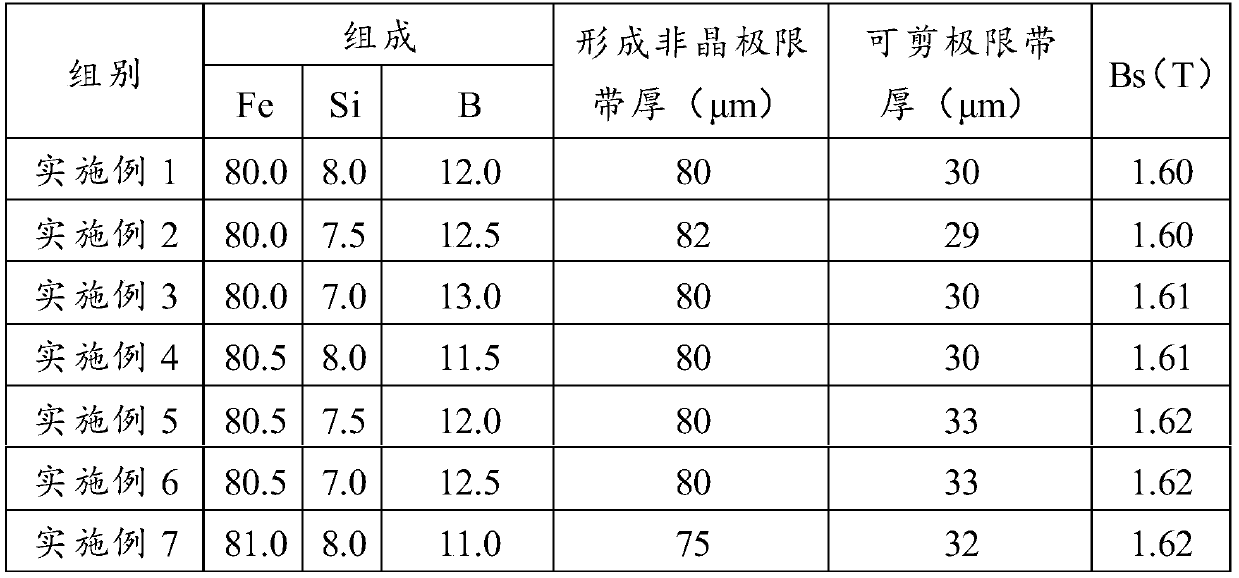

[0054] 1) Preparation of iron-based amorphous alloy strips

[0055] According to Fe a B b Si c The indicated alloy composition is used for batching, and the alloy composition shown in Table 1 is prepared by using industrial pure iron, silicon, and ferroboron; in addition to the main elements, the alloy composition has inevitable impurity elements, such as C, Mn, S, etc. Put the materials with different ingredients in the order of ferroboron, silicon and pure iron into the intermediate frequency induction smelting furnace with a furnace capacity of 100kg for remelting (melting temperature is 1300-1500℃, time is 80-120min); molten steel is quenched Finished, poured into the spray ladle, and the amorphous strip with a bandwidth of 20 mm was prepared by the single-roll plane flow casting method. During the strip-making process, alloy composition strips with different strip thicknesses were prepared by adjusting parameters such as roll speed and liquid level ( The roller speed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com