Cold-forming mould for heavy load fiber molding trays and cold press moulding method

A cold-pressing and cold-forming technology, applied in textiles and papermaking, etc., can solve the problems of difficult to form complex thick-walled structures, large deformation, low load, etc., to overcome the serious disconnection between production and design, low work costs, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

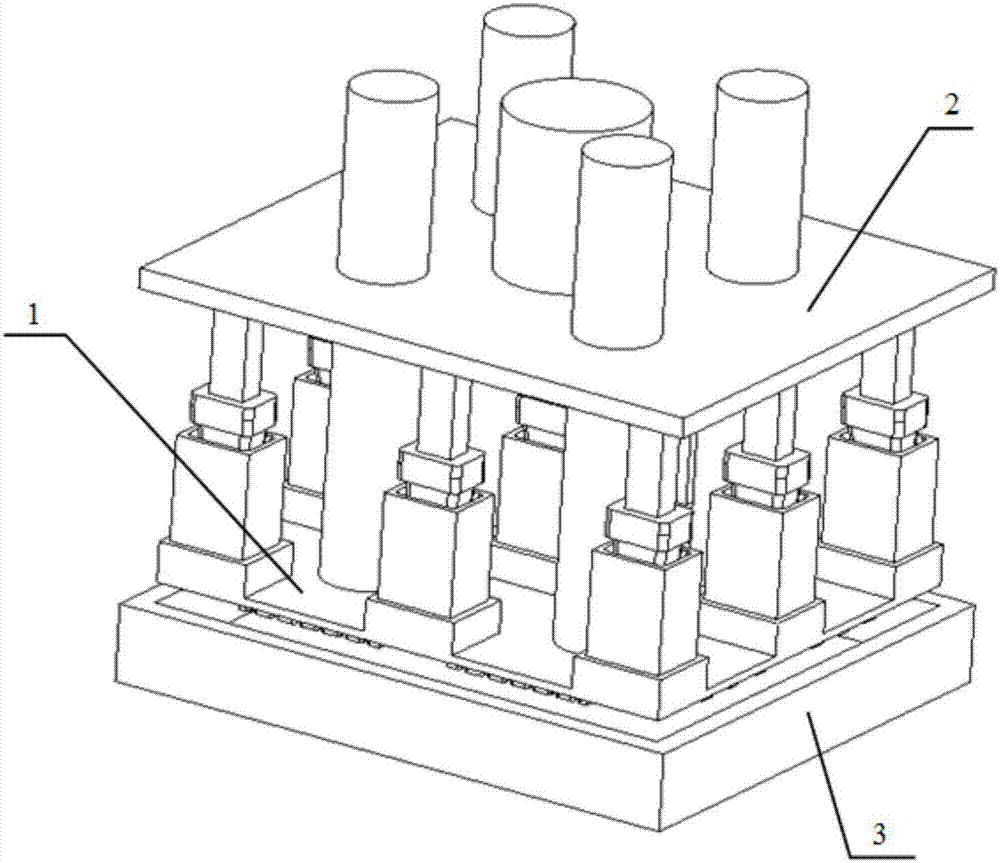

[0046] Embodiment 1. As shown in the drawings, the embodiment of the present invention provides a cold forming mold for a heavy-duty fiber molded tray, including a panel die 3, a panel die 1 and a leg die 2;

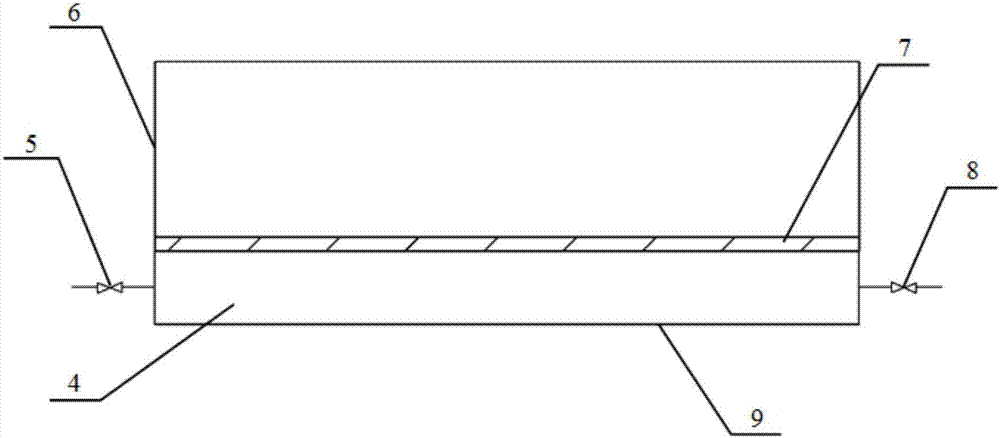

[0047]The panel die 3 is an open box structure, and a panel die net mold 7 is horizontally arranged between the panel die side walls 6, and a panel die cavity is formed between the panel die net die 7 and the panel die bottom plate 9 4. A drain valve 5 and a gas valve 8 are installed on the side wall of the cavity 4 of the panel die;

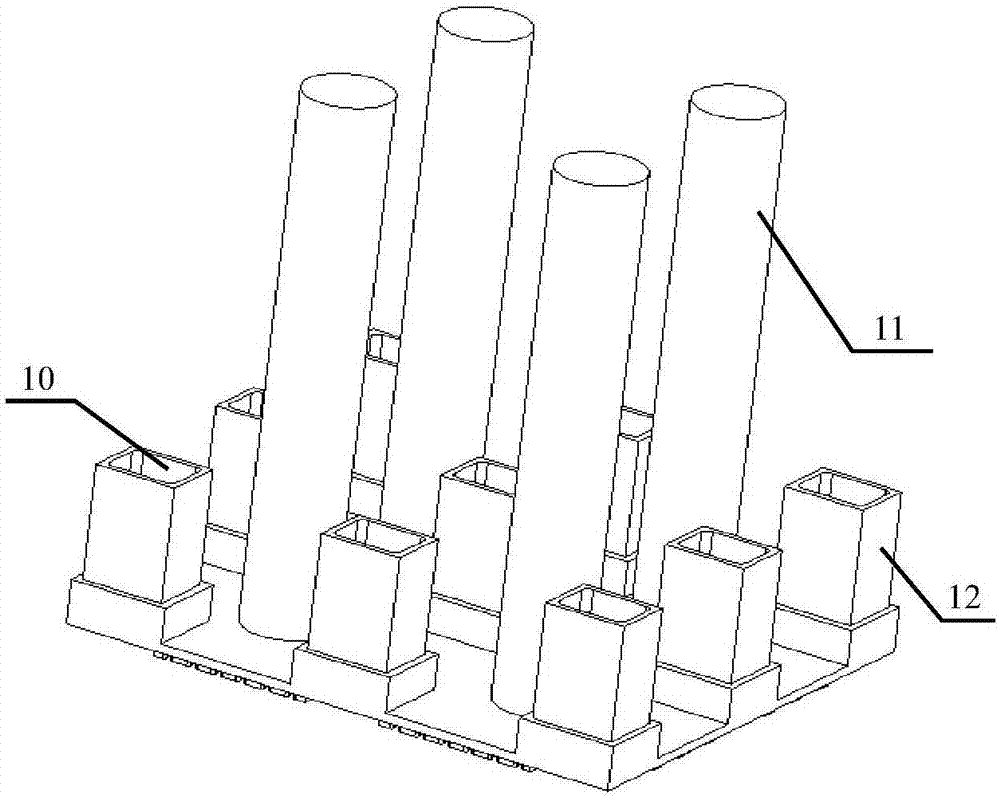

[0048] The panel pressing die 1 comprises a panel pressing die top plate 16, a panel punch 14, a leg die 13, a leg mold box 12 and a first lift cylinder 11, and the panel pressing die top plate 16 is provided with a plurality of first Lifting cylinder 11, a plurality of panel punches 14 and a plurality of leg dies 13 are arranged below the panel die top plate 16, and the leg dies 13 extend upwards to the top of the panel die top plate, and...

Embodiment 2

[0055] Embodiment 2, as shown in the accompanying drawings, this embodiment of the present invention provides a method for cold-pressing a heavy-duty fiber molded tray, which is based on the cold-press molding method for a heavy-duty fiber molded tray described in Example 1. The forming mold is realized, the specific steps are:

[0056] 1. Inject a certain concentration of fiber suspension required for heavy-duty fiber molding pallet panels into the panel die 3;

[0057] 2. Open the drain valve 5 of the cavity 4 of the panel die, and after the water has leaked out, under the action of the first lift cylinder 11 and the second lift cylinder 21, the panel die 1 and the leg die 2 are inserted into the panel In the die 3, at the same time, the die cavity 15 of the panel punch and the leg die, the die cavity 26 of the leg punch, and the panel die cavity 4 are connected to the vacuum, and the fiber slurry is mechanically extruded and processed for a certain period of time. Suction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com