System and method for moving and assembling the upper section of prefabricated underground passage

An underground passage and prefabricated assembly technology, applied in underwater structures, buildings, artificial islands, etc., can solve the problems of difficulty in controlling safety risks and heavy weight in large-scale hoisting construction, reduce compensation for demolition, reduce comprehensive costs, Avoid the effect of restrictive requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

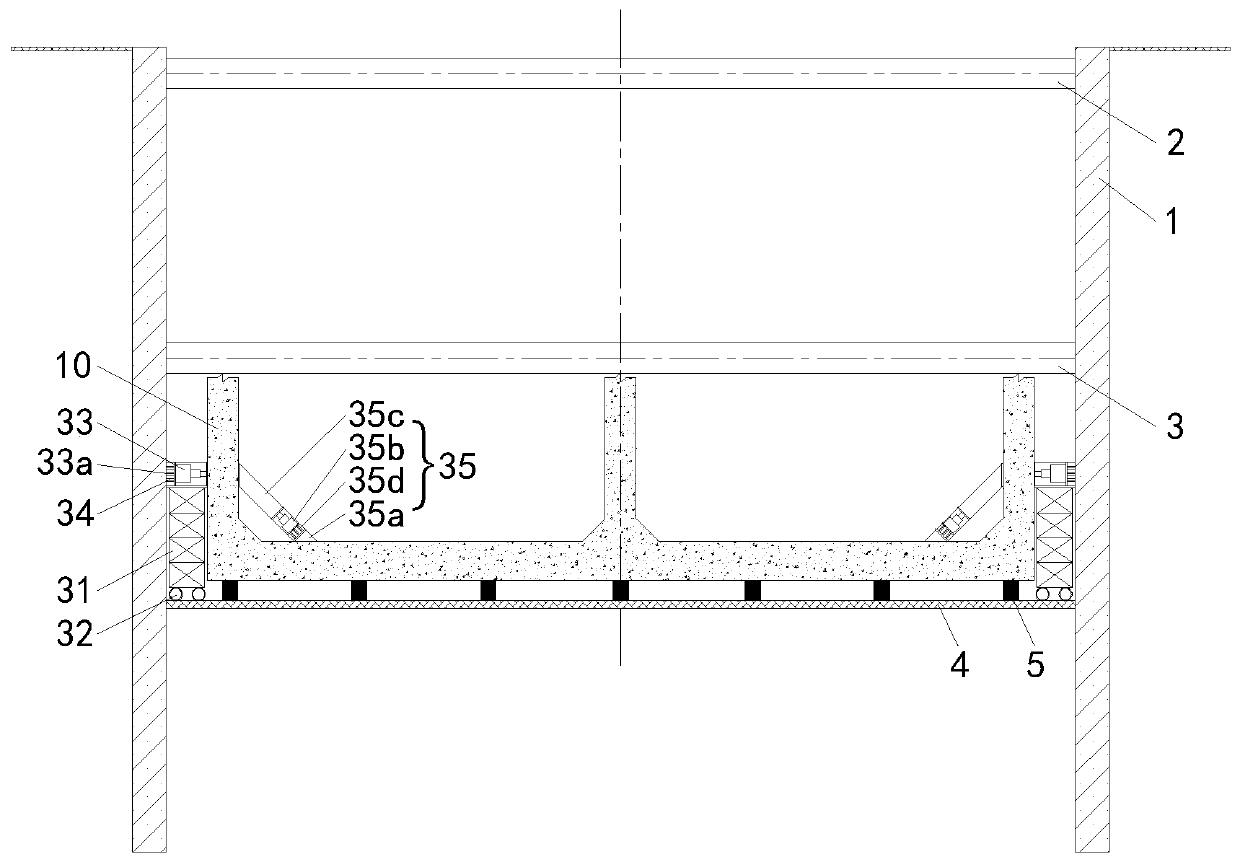

[0030] Embodiment 1: The underground passage structure of this embodiment is a double-hole underground passage with a rectangular longitudinal section. In order to facilitate the prefabrication of the underground passage structure, the underground passage structure is vertically divided into several sections before construction, and each section The section is divided horizontally into the upper section 20 of the underground passage and the lower section 10 of the underground passage. The section 10 of the lower section of the underground passage is jacked into place and then assembled into the lower structure of the underground passage. Figure 4 Describe the transfer and assembly system of the upper section of the prefabricated underground passage of the present invention, the transfer and assembly system includes a support body 50, a self-propelled slide rail 51, a vertical adjustment mechanism 52 and a horizontal adjustment mechanism 54, and the self-propelled slide rail 51...

Embodiment 2

[0034] Embodiment two: combine below Figure 1 to Figure 6 The method for moving and assembling the upper section of the prefabricated underground passage of the present invention is illustrated, and the specific construction steps are as follows:

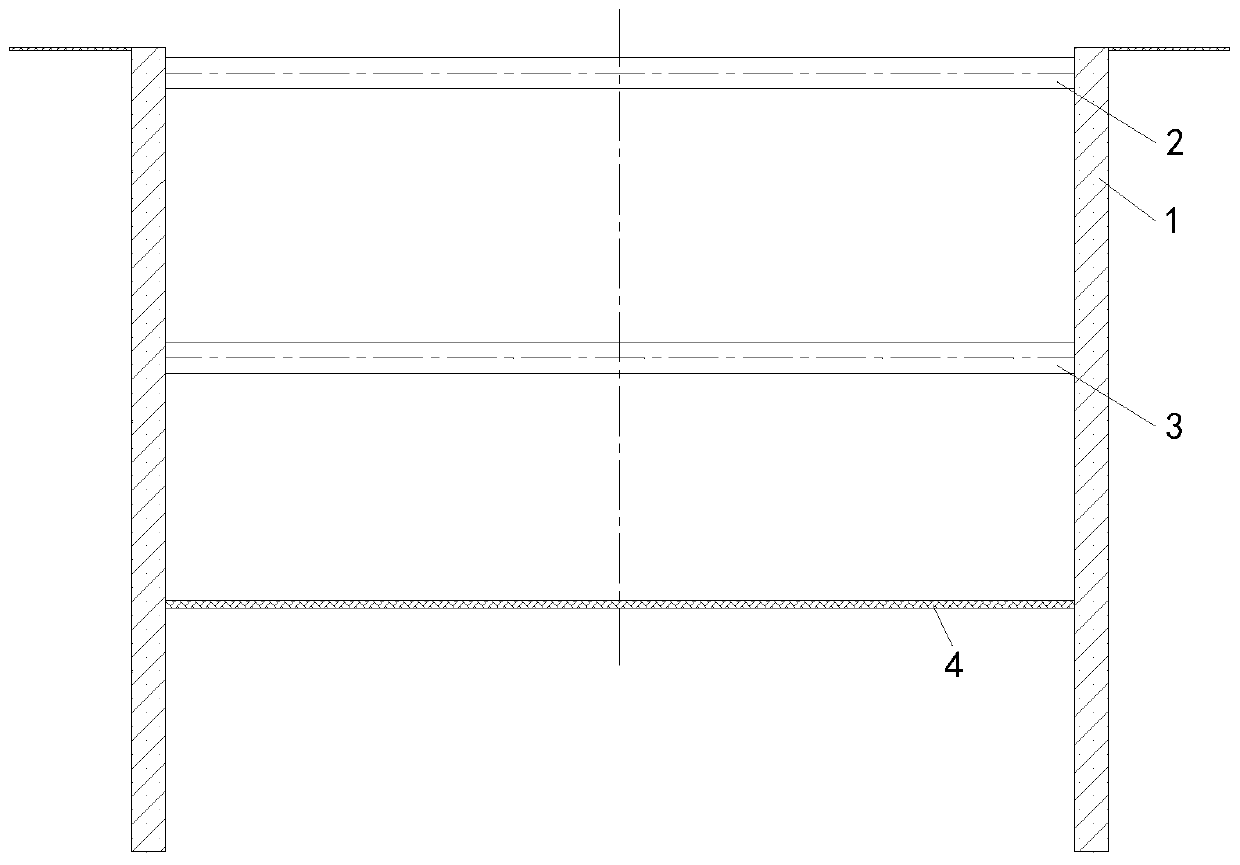

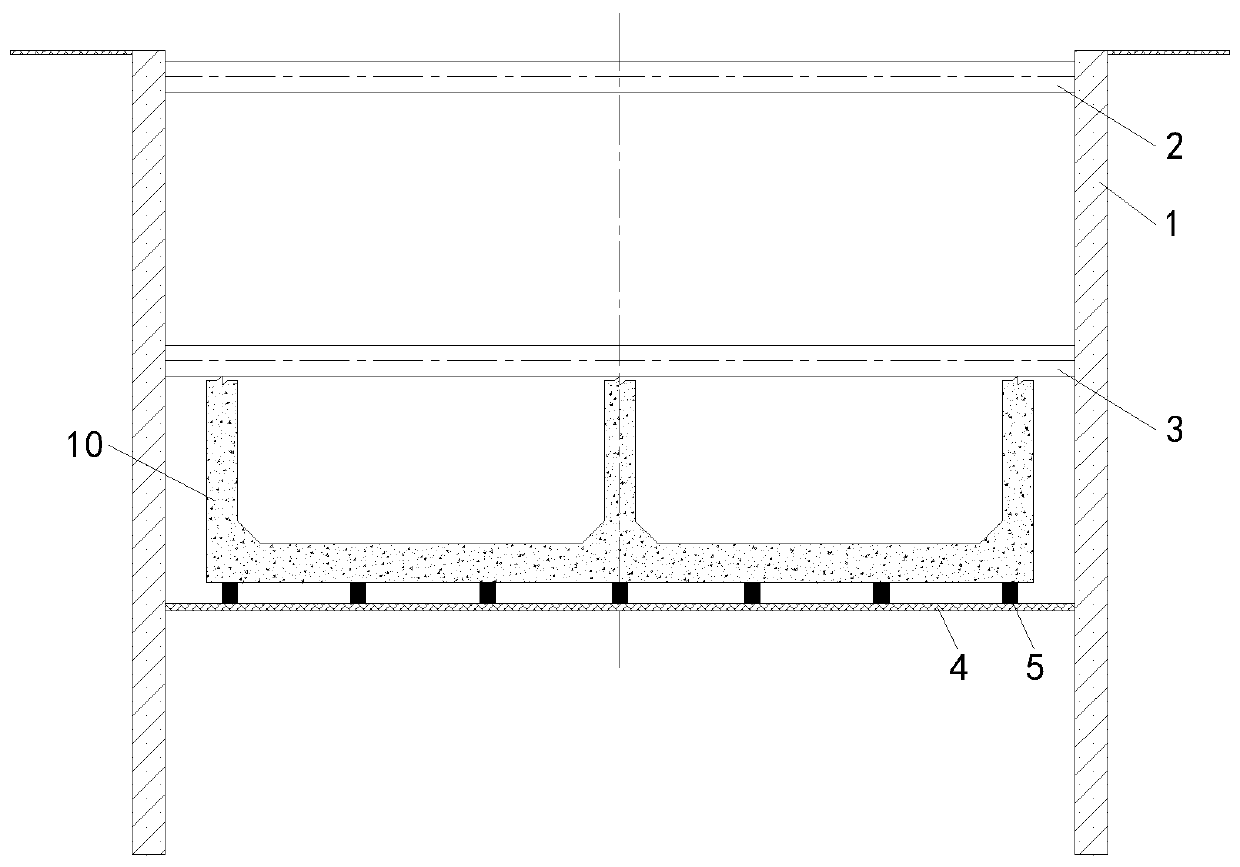

[0035] S101: if figure 1 As shown, the construction of the enclosure structure 1 of the underground passage, the earth excavation and the construction of the supporting structure are carried out in batches, and the reinforced concrete cushion 4 is poured. Specifically, the enclosure structure 1 of the underground passage is constructed first, and the first batch of Excavate the earthwork and construct the first reinforced concrete support 2. After the first reinforced concrete support 2 reaches the strength required by design, carry out the second batch of earthwork excavation, and construct the second reinforced concrete support 3 after completion; After the second reinforced concrete support 3 is formed, the third batch of earth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com