Supporting structure used for engineering building

A technology for supporting structures and buildings, applied in building structures, buildings, and on-site preparation of building components, etc., can solve the problems of short service life, reduced rigidity strength of pillars, and easy rust, so as to reduce construction costs and improve The effect of working efficiency and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

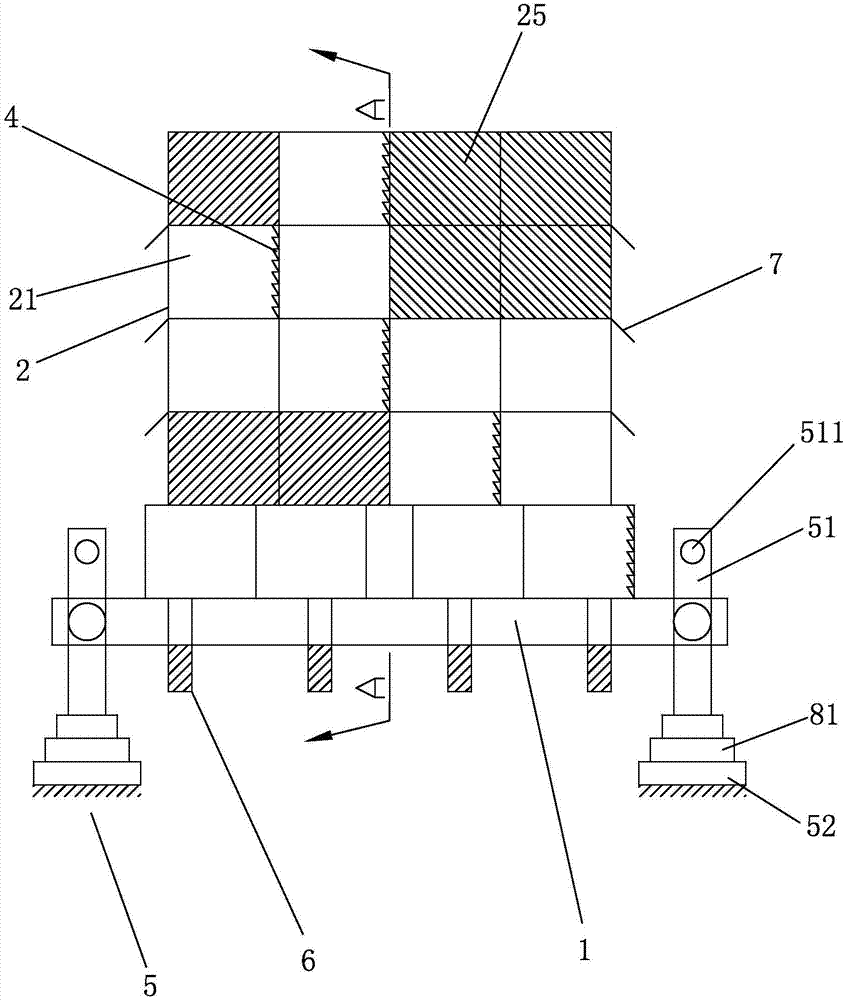

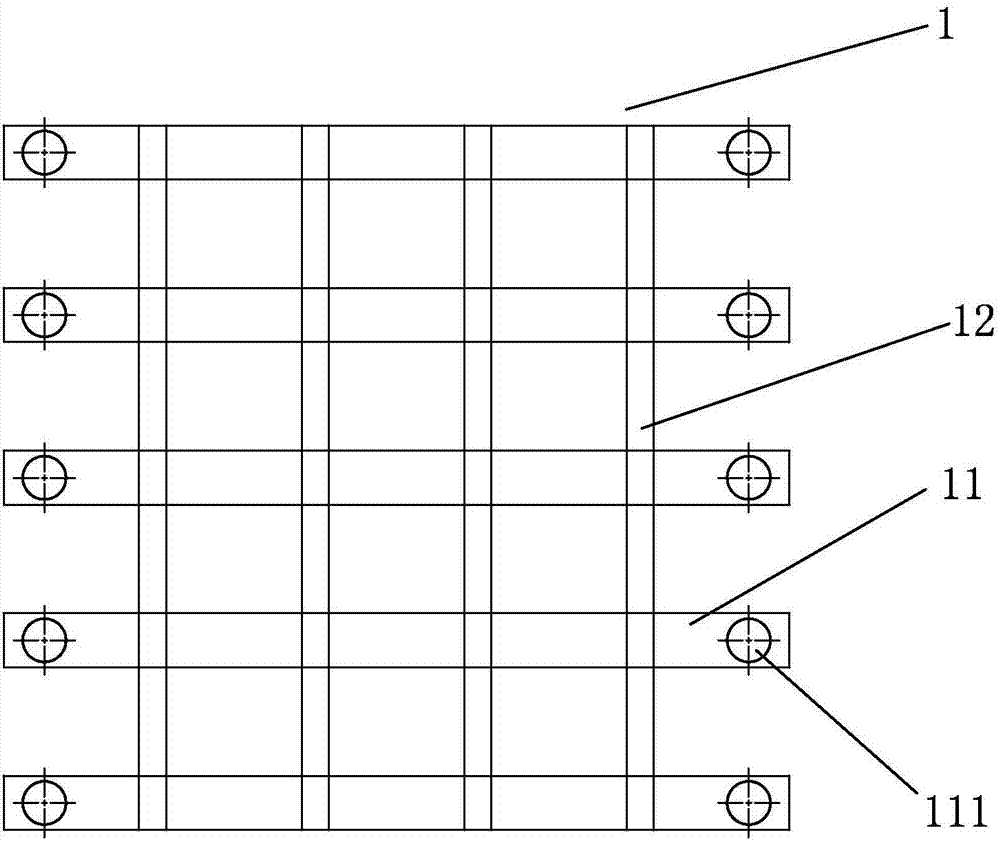

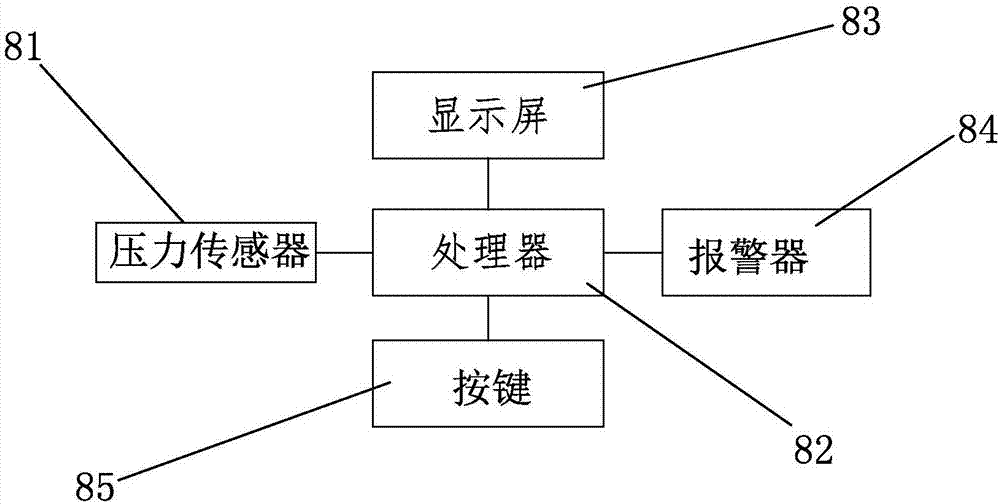

[0061] A support structure used in engineering buildings. It is used as a support structure in construction projects and needs to bear a certain load. A supporting structure used in engineering buildings, comprising: a supporting platform, and a space supporting body arranged on the supporting platform. The space support body includes a plurality of support units stacked vertically or / and horizontally, and is used for connecting multiple connecting pieces of adjacent support units. The support unit is provided with passage gaps, and the passage gaps of adjacent support units are connected to form a passage together with the inner space of the support units, and the space support body is detachably connected to the support platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com