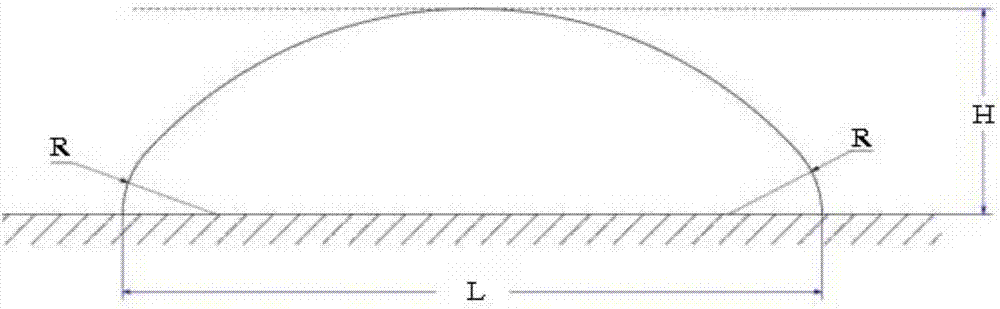

Composite material and steel structure mixed super-large span material storage shed and construction method thereof

A composite material and steel structure technology, applied in the field of building structures, can solve the problems that the inflatable film formwork and the keel skeleton cannot be produced, cannot be widely promoted and applied, and the construction cost is high, so as to save the construction period and installation cost, and the overall structure tends to be Stable and reasonable force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

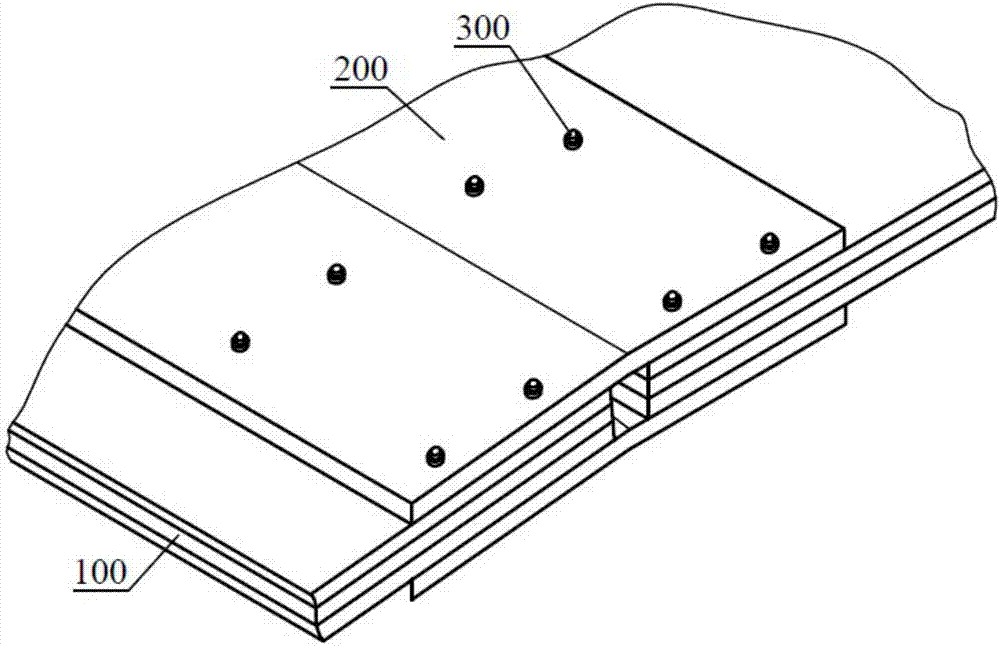

[0043] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0044] With the development and innovation of composite materials, there are a variety of composite materials suitable for large-span storage sheds. The composite materials are made of glass fiber, carbon fiber, etc. and resin materials, and are formed by winding, molding, and pultrusion. Among them, the use of a new type of composite material - honeycomb composite panels, the span of the storage shed without supporting columns in the middle can be built larger and larger.

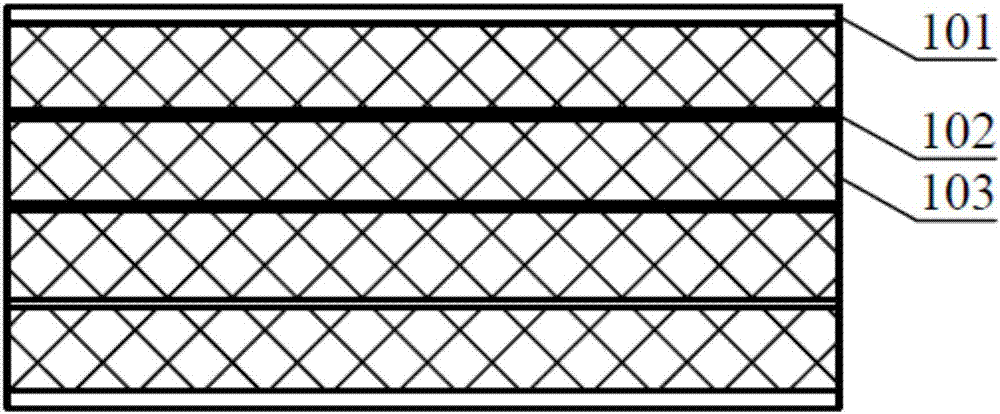

[0045] The above-mentioned honeycomb composite plate is composed of a honeycomb layer in the middle of the panels on both sides and an adhesive layer bonding the honeycomb layer and the panel, and has excellent performance. It is mainly reflected in low density, high strength, flame retardancy and heat prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com