Telegraph pole for building construction

A technology for construction and utility poles, applied in the field of utility poles for construction, can solve the problems of short service life, low structural strength, and poor corrosion resistance of the insulating layer, and achieves high overall structural strength, reduced structural weight, and good performance. The effect of the anti-vibration function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

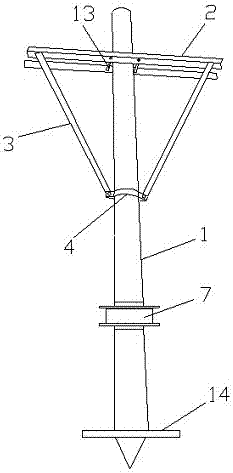

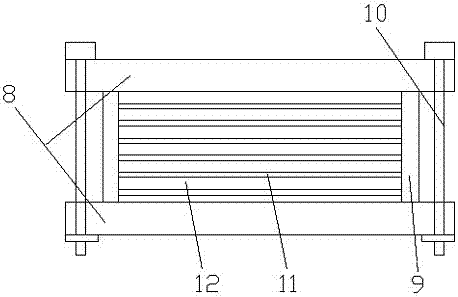

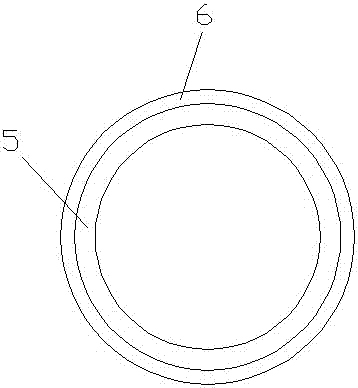

[0022] like Figure 1-Figure 3 As shown, a utility pole for building construction includes a pole body 1, two angle irons 2, two support rods 3 and a hoop 4. The pole body 1 includes a hollow metal tube 5 and a metal tube 5 outside Insulation layer 6, the two angle irons 2 are horizontally clamped on both sides of the rod body 1, and the tops of the two support rods 3 are welded to the two ends of an angle iron 2 at an inclination angle extending outward, and the hoop 4 Set at the end of the support rod 3 and cover the outside of the rod body 1, the middle part of the rod body 1 is provided with a shock-absorbing support 7, the shock-absorbing support 7 includes two steel plates 8 and a rubber sleeve 9, and the rubber sleeve 9 is arranged on the Between the two steel plates 8 , the two steel plates 8 are connected by anchor bolts 10 , and steel plates 11 and rubber plates 12 are arranged alternately in the rubber sleeve 9 .

[0023] The middle parts of the two angle irons 2 a...

Embodiment 2

[0034] like Figure 1-Figure 3 As shown, a utility pole for building construction includes a pole body 1, two angle irons 2, two support rods 3 and a hoop 4. The pole body 1 includes a hollow metal tube 5 and a metal tube 5 outside Insulation layer 6, the two angle irons 2 are horizontally clamped on both sides of the rod body 1, and the tops of the two support rods 3 are welded to the two ends of an angle iron 2 at an inclination angle extending outward, and the hoop 4 Set at the end of the support rod 3 and cover the outside of the rod body 1, the middle part of the rod body 1 is provided with a shock-absorbing support 7, the shock-absorbing support 7 includes two steel plates 8 and a rubber sleeve 9, and the rubber sleeve 9 is arranged on the Between the two steel plates 8 , the two steel plates 8 are connected by anchor bolts 10 , and steel plates 11 and rubber plates 12 are arranged alternately in the rubber sleeve 9 .

[0035] The middle parts of the two angle irons 2 a...

Embodiment 3

[0046] like Figure 1-Figure 3 As shown, a utility pole for building construction includes a pole body 1, two angle irons 2, two support rods 3 and a hoop 4. The pole body 1 includes a hollow metal tube 5 and a metal tube 5 outside Insulation layer 6, the two angle irons 2 are horizontally clamped on both sides of the rod body 1, and the tops of the two support rods 3 are welded to the two ends of an angle iron 2 at an inclination angle extending outward, and the hoop 4 Set at the end of the support rod 3 and cover the outside of the rod body 1, the middle part of the rod body 1 is provided with a shock-absorbing support 7, the shock-absorbing support 7 includes two steel plates 8 and a rubber sleeve 9, and the rubber sleeve 9 is arranged on the Between the two steel plates 8 , the two steel plates 8 are connected by anchor bolts 10 , and steel plates 11 and rubber plates 12 are arranged alternately in the rubber sleeve 9 .

[0047] The middle parts of the two angle irons 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com