Manufacturing technology of honeycomb aluminum core composite lightweight wallboard

A light-weight wallboard and manufacturing process technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of complex light-weight wallboard manufacturing process, poor sound insulation effect, and low production efficiency, and achieve low cost and high thickness. Diversification and high productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

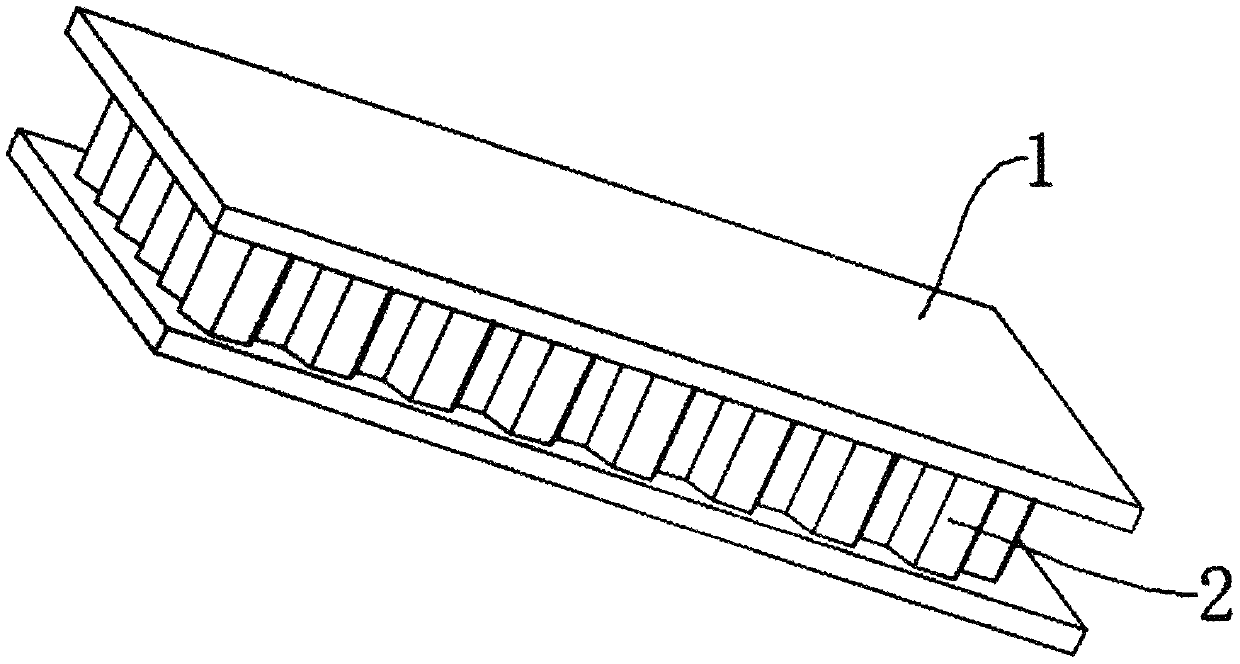

[0027] A manufacturing process of honeycomb aluminum core composite lightweight wallboard, the steps are as follows:

[0028] 1) Plate glue coating;

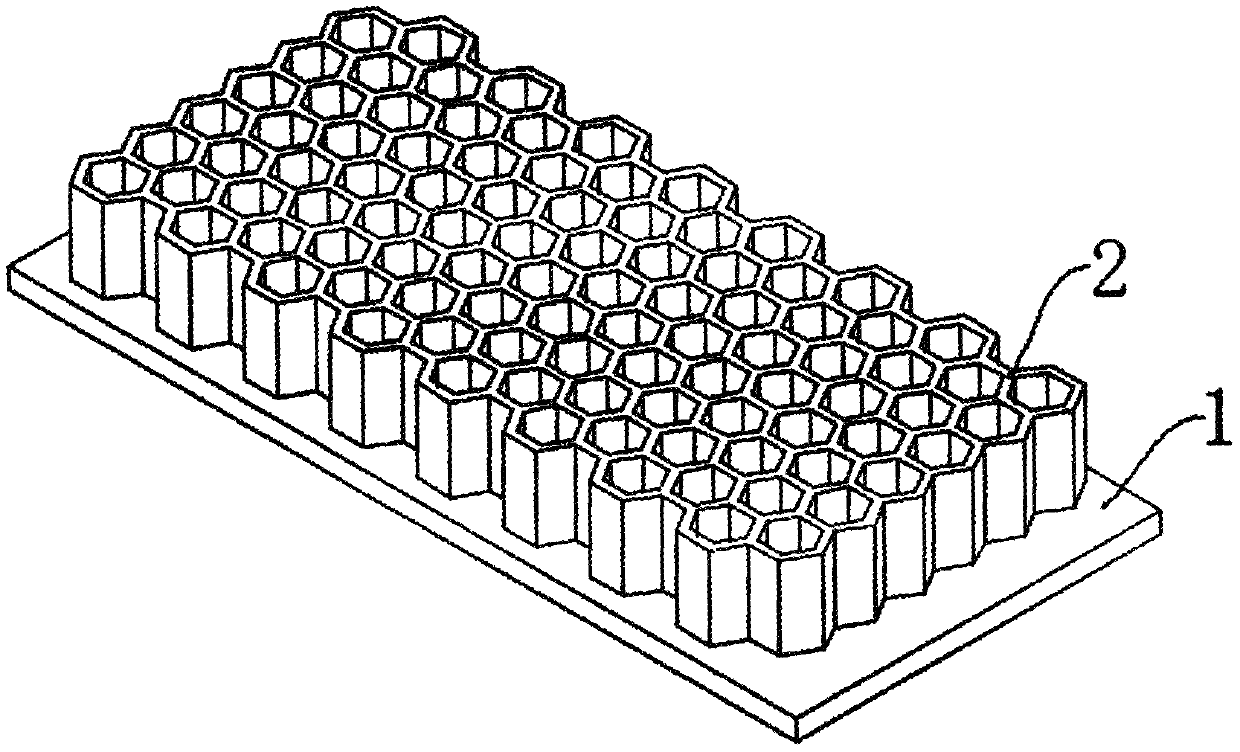

[0029] 2) Stretch honeycomb aluminum core;

[0030] 3) Composite: Composite the plate in step 1) with the honeycomb aluminum core in step 2);

[0031] 4) Machine cold pressing: cold pressing the composite wallboard completed in step 3).

[0032] Wherein, there are two plates in the step 1).

[0033] The two boards are respectively located on both sides of the honeycomb aluminum core.

[0034] The board described in step 1) is a cement board, and the cement board can also be replaced by a galvanized board.

[0035] The glue described in step 1) is an environmentally friendly polyurethane glue.

Embodiment 2

[0037] A manufacturing process of honeycomb aluminum core composite lightweight wallboard, the steps are as follows:

[0038] 1) Plate glue coating;

[0039] 2) Stretch honeycomb aluminum core;

[0040] 3) Composite: Composite the plate in step 1) with the honeycomb aluminum core in step 2);

[0041] 4) Machine cold pressing: cold pressing the composite wallboard completed in step 3).

[0042] Wherein, there are two plates in the step 1).

[0043] The two boards are respectively located on both sides of the honeycomb aluminum core.

[0044] The board described in step 1) is an aluminum board, and a calcium silicate board can also be used instead of the aluminum board.

[0045] The glue described in step 1) is an environmentally friendly polyurethane glue.

Embodiment 3

[0047] A manufacturing process of honeycomb aluminum core composite lightweight wallboard, the steps are as follows:

[0048] 1) Plate glue coating;

[0049] 2) Stretch honeycomb aluminum core;

[0050] 3) Composite: Composite the plate in step 1) with the honeycomb aluminum core in step 2);

[0051] 4) Machine cold pressing: cold pressing the composite wallboard completed in step 3).

[0052] Wherein, there are two plates in the step 1).

[0053] The two boards are respectively located on both sides of the honeycomb aluminum core.

[0054] The board described in step 1) is a magnesium oxide board, and an acrylic board can also be used instead of the magnesium oxide board.

[0055] The glue described in step 1) is an environmentally friendly polyurethane glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com