Oil-water well circulating cleaning system

A technology of cleaning system and circulation system, applied in cleaning equipment, wellbore/well components, filtration and separation, etc., can solve the problems of high processing cost, difficult cleaning of well cleaning fluid, lying well, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Well flushing system

[0031] The water well circulation cleaning system includes a carrying tool, a water filtration system, and a circulation system. The water filtration system is fixed on the carrying tool, and the water filtration system is connected through the circulation system to realize water filtration and circular well cleaning;

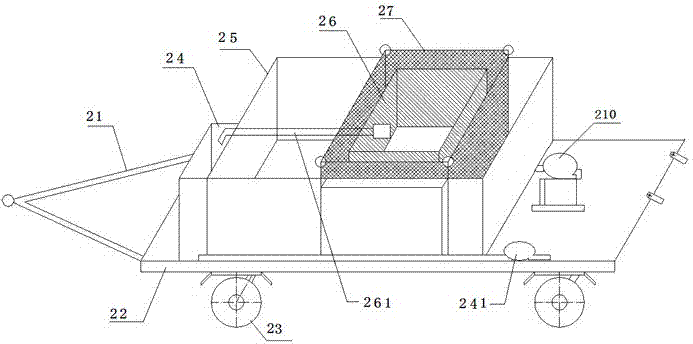

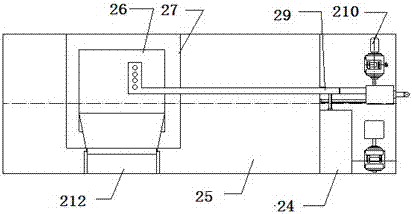

[0032] The carrying tool includes a drag bar 21, a frame body 22, and support rollers 23. The front end of the frame body 22 is provided with a drag bar 21, the bottom of the frame body 22 is provided with a support roller 23, and the top of the frame body 22 is provided with a water filtration system, Circulation system, the circulation system includes plunger pump and control valve;

[0033] The water filtration system includes an oil pollution tank 24, a jellyfish filter tank 25, a primary water filter sub-tank 26, a secondary water filter sub-tank 27, a fixed secondary filter water sub-tank 27 in the middle of the...

Embodiment 2

[0041] Example 2: Oil Well Flushing System

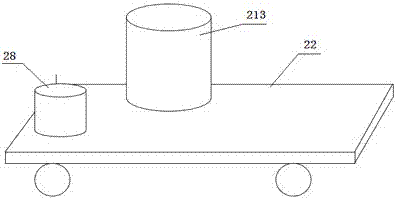

[0042] The oil well circulation cleaning system includes two sets of carrier tools, water filtration system, heating system, and circulation system. One set of carrier tools is fixed with a water filtration system, and the other set of carrier tools is fixed with a heating system. The water filtration system and the heating system are connected through the circulation system. Realize water filtration and heating liquid circulation to wash wells.

[0043] The carrying tool includes a drag rod 21, a frame body 22, and a support roller 23. The front end of the frame body 22 is provided with a drag rod 21, the lower part of the frame body 22 is provided with a support roller 23, and the upper part of the frame body 22 is provided with a water filter system, Circulation system, the circulation system includes plunger pump and control valve;

[0044] The water filtration system includes an oil pollution tank 24, a jellyfish tank 25, a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com