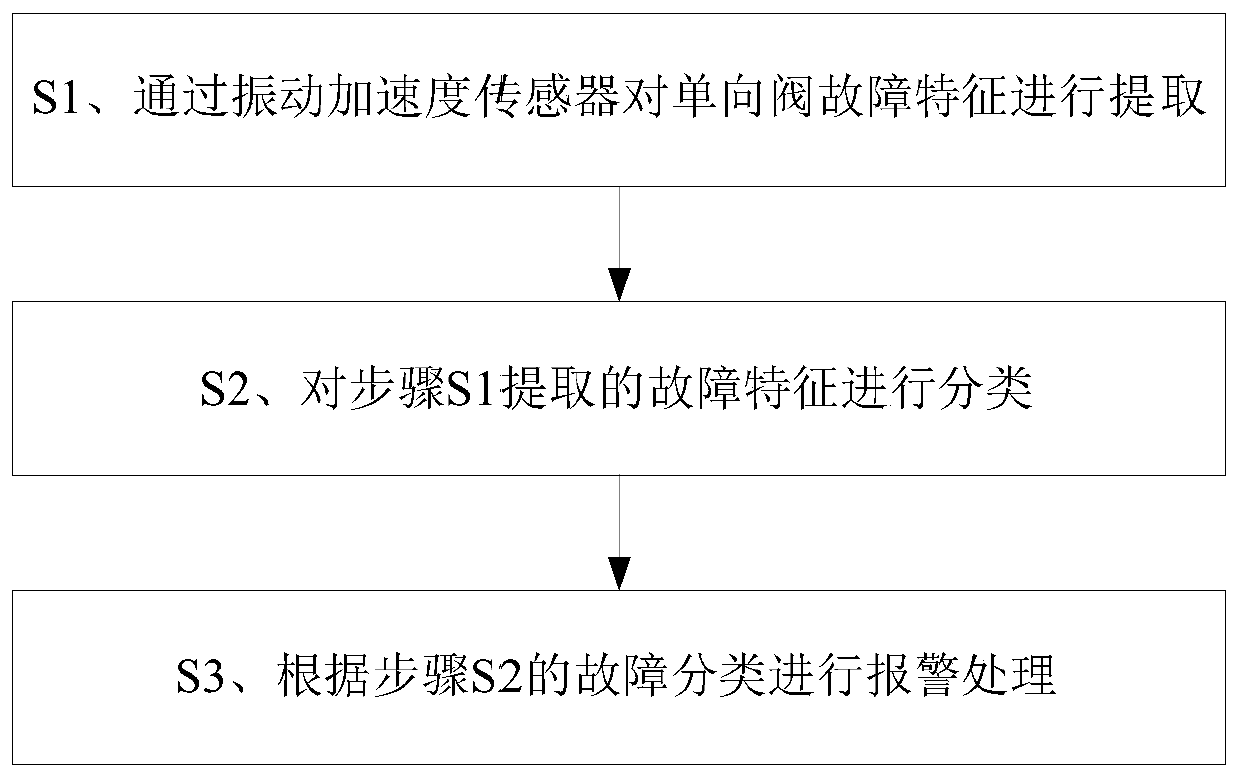

A method and system for real-time fault detection of diaphragm pump check valve

A real-time fault and detection method technology, applied in pump testing, pump, pump parameters, etc., can solve the problems of low availability, difficult promotion, and high manufacturing costs, so as to reduce fault detection costs, avoid working conditions, and reduce redundancy. effect of redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

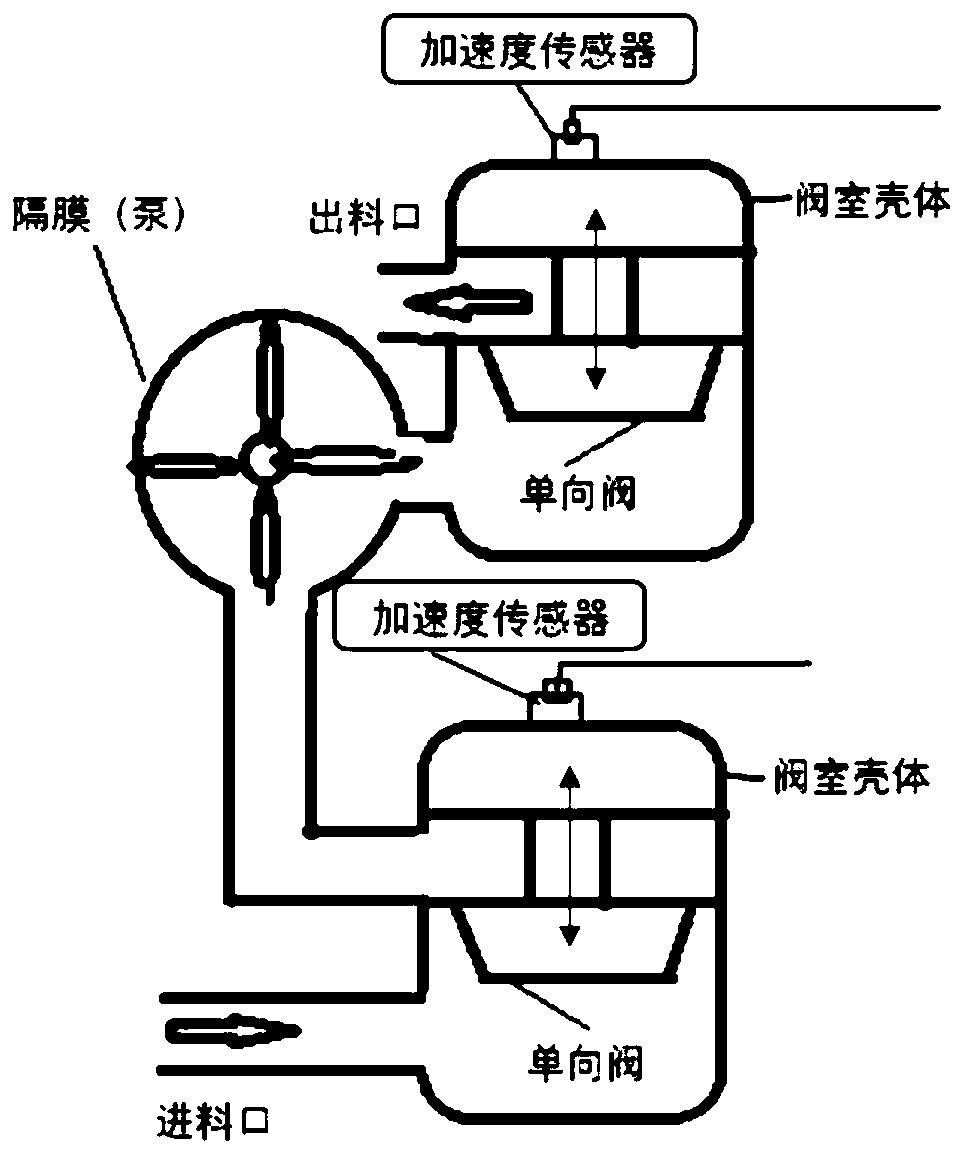

[0043] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

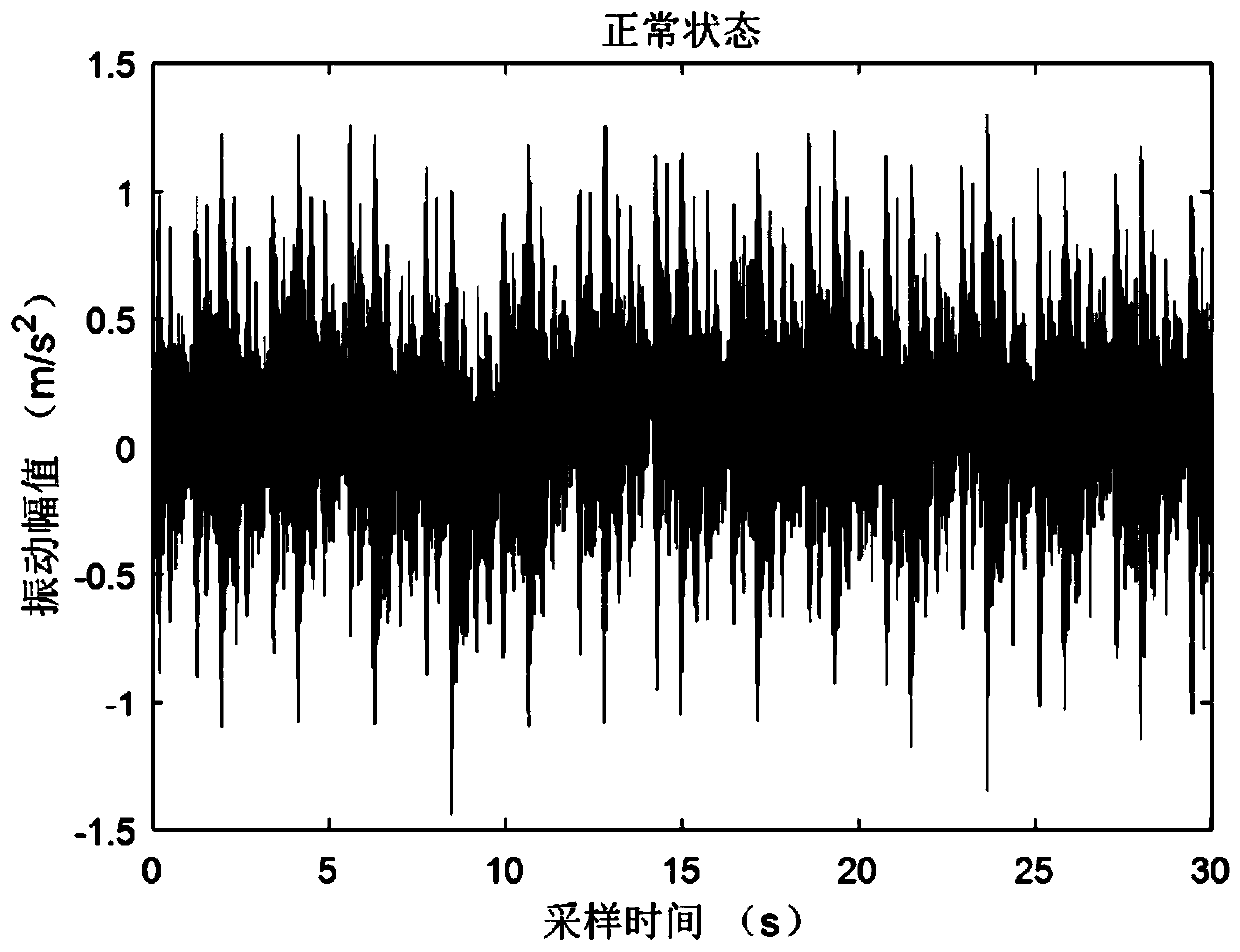

[0044] Through tests, the vibration impact degree of the check valve, the vibration continuation degree of the check valve and the vibration energy value of the check valve proposed by the present invention, these three types of indicators have the highest accuracy in the fault detection of the check valve; and the vibration impact of the check valve The degree, the vibration duration of the one-way valve and the vibration energy value of the one-way valve are three types as the one-way valve fault detection indicators, which are proposed for the first time in this application.

[0045]In order to collect vibration acceleration information when the check valve is working, a vibration acceleration sensor is installed on the upper end of the valve c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com