Film stretching device

A stretching device and film technology, which is applied in the field of stretching devices with a stretching ratio, can solve the problems of low production efficiency, inability to precisely control, and uneven stretching, etc., and achieve optical performance improvement, uniformity, barrier The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

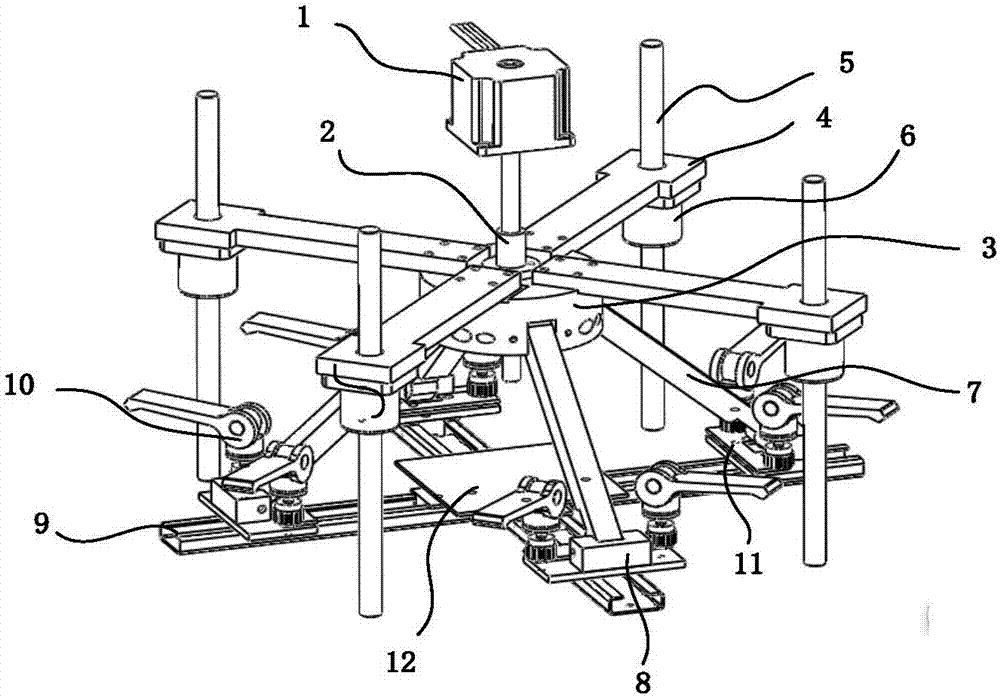

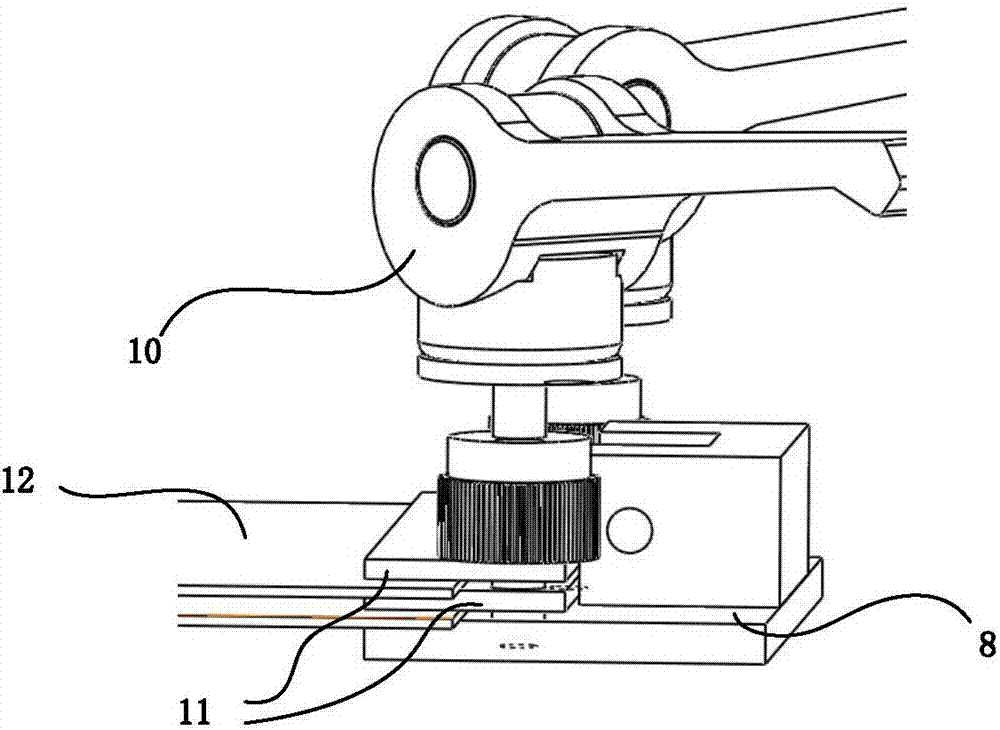

[0018] refer to figure 1 , 2 , the film stretching device of the present invention includes: a horizontal motion plate 3 with four support arms 4 evenly distributed along its circumference, the outer end of each support arm 4 is respectively inserted through a linear bearing 6 and fixed on the base (not marked in the figure) on the vertical guide shaft 5, on the horizontal motion plate 3 outer edges, hinge four connecting rods 7 uniformly distributed along its circumference, and the lower end of each connecting rod 7 is hinged with a slide table 8, The slide rail 9 matched with the slide table 8 is fixed on the base, and the four slide rails 9 are distributed along the outer circumference of the center of the moving plate 3; The output screw shaft of the linear motor 1 on the frame (not shown in the figure) is driven and connected, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com