Time-varying fractional FCOR multi-axis coordinated control system performance evaluation method

A system performance evaluation and collaborative control technology, which is applied in the general control system, control/regulation system, test/monitoring control system, etc., can solve the problems of limited accuracy of evaluation results and inaccurate model description, and achieve high model description Precision, accurate system evaluation results, high reliability results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

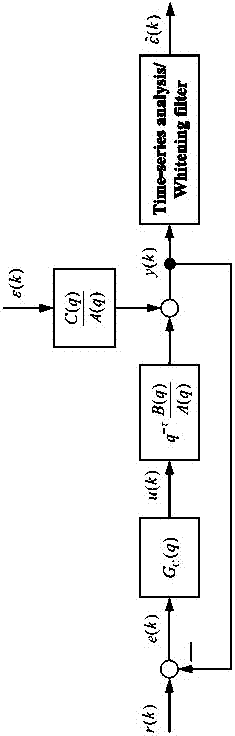

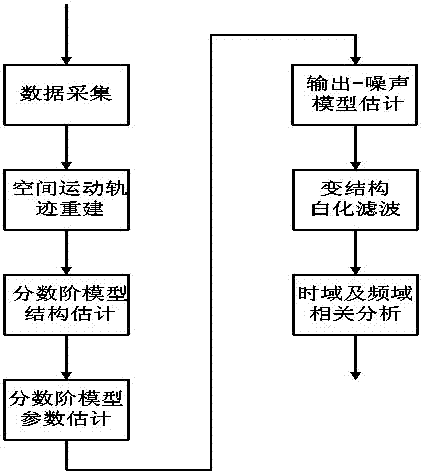

[0028] Such as figure 2 As shown, the present invention discloses a method for evaluating the performance of a time-varying fractional order FCOR multi-axis cooperative control system. The multi-axis cooperative control system to be evaluated includes a lower-level controller connected to a power amplifier as a controlled object, Servo motors and motion sensors;

[0029] This method is carried out through an external system performance evaluation module, the external system performance evaluation module includes a CPU (central processing unit), a communication module and a memory, and the communication module and the memory are respectively connected to the CPU; the communication module and the multi-axis cooperative control system being evaluated The lower controllers are connected in a wired or wireless manner; the initial output-noise model is built in the CPU and / or memory of the external system performance evaluation module;

[0030] This method is carried out in turn b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com