Cold sterilization and preservation method of fresh egg liquid

A technology for cold sterilization and fresh egg liquid is applied in the field of cold sterilization and preservation of fresh egg liquid, which can solve the problems of prolonging the shelf life of egg liquid products and poor dissolving effect, and achieves the effects of improving sterilization effect, prolonging shelf life and enhancing penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

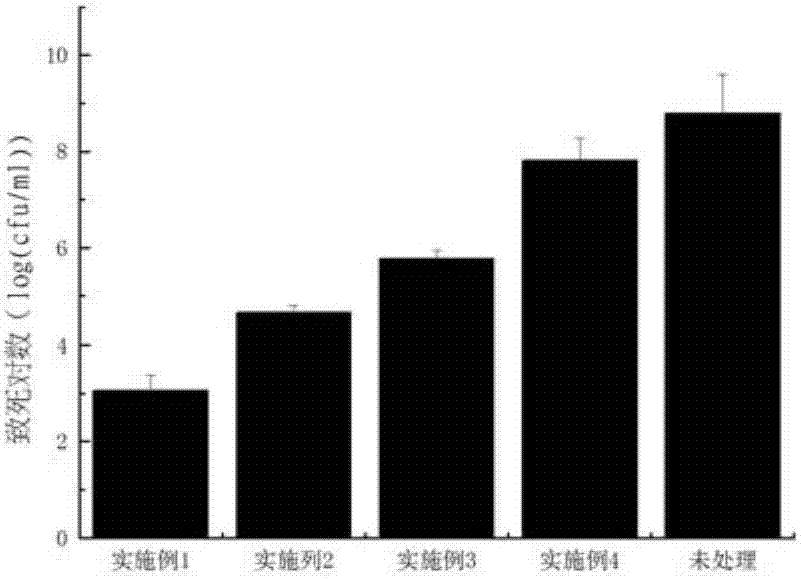

Embodiment 1

[0082] 1) Pretreatment of eggs:

[0083] Choose fresh eggs that meet hygienic standards, wash the surface of the eggshell with clean water and air-dry, then beat the eggs in a clean environment, take the egg liquid and stir evenly;

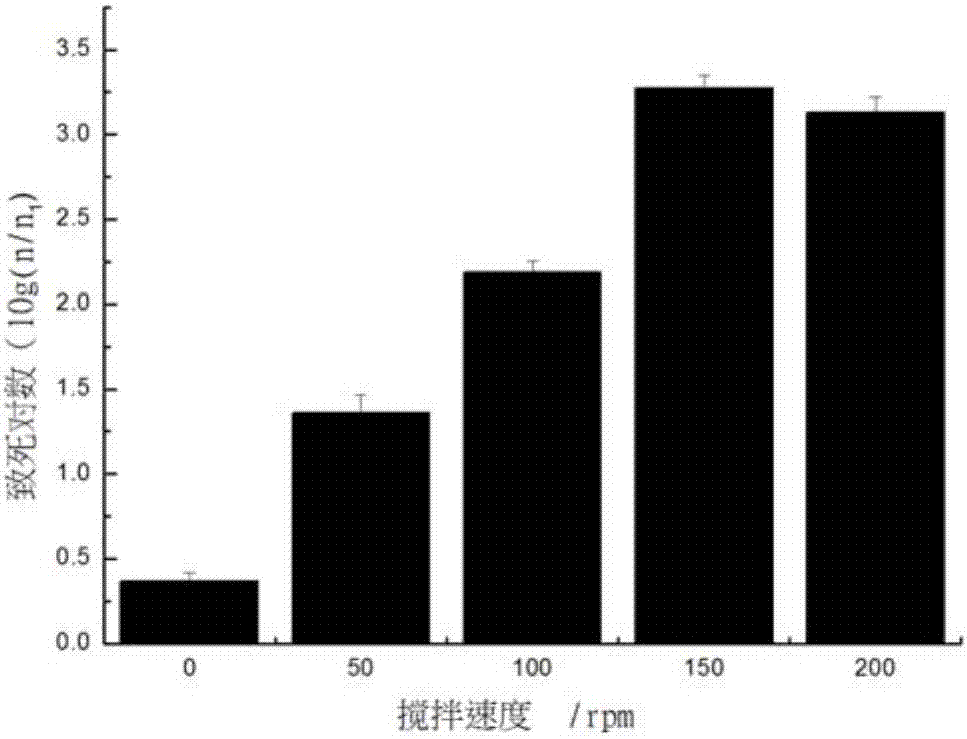

[0084] 2) High density CO 2 Sterilization treatment:

[0085] Place the homogeneous egg liquid in high-density CO 2 , the pressure is 4Mpa, the stirring speed is 50rpm, and the temperature is 24°C, the sterilization treatment is 10min, the ultraviolet light and ozone are turned on, and then the treated egg liquid is aseptically packaged / aseptically filled; the primary product is obtained;

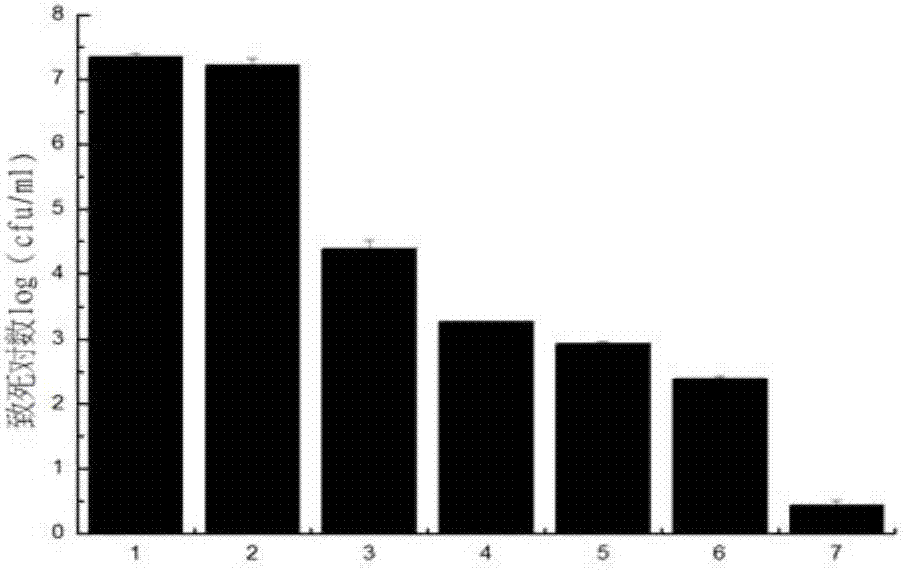

[0086] 3) Ultra-high pressure and ultrasonic co-processing:

[0087] Put the primary product in the ultrasonic treatment container, the ultrasonic power is 100W, and process for 10 minutes; after the ultrasonic treatment is completed, put it into the ultra-high pressure sterilization container, pressurize to 50MPa, keep it for 5 minutes, and take it out afte...

Embodiment 2

[0089] 1) Pretreatment of eggs:

[0090] Choose fresh eggs that meet hygienic standards, wash the surface of the eggshell with clean water and air-dry, then beat the eggs in a clean environment, take the egg liquid and stir evenly;

[0091] 2) High density CO 2 Sterilization treatment:

[0092] Place the homogeneous egg liquid in high-density CO 2 , Sterilize for 15 minutes under the conditions of pressure 6Mpa, stirring speed 75rpm, and temperature 26°C, turn on the ultraviolet light and ozone, and then carry out aseptic packaging / aseptic filling of the treated egg liquid; obtain the primary product;

[0093] 3) Ultra-high pressure and ultrasonic co-processing:

[0094] Place the primary product in an ultrasonic treatment container with an ultrasonic power of 120W / cm 2 , treated for 12 minutes; after the ultrasonic treatment is completed, put it into an ultra-high pressure sterilization container, pressurize it to 100MPa, keep it for 10 minutes, and take it out after the ...

Embodiment 3

[0096] 1) Pretreatment of eggs:

[0097] Choose fresh eggs that meet hygienic standards, wash the surface of the eggshell with clean water and air-dry, then beat the eggs in a clean environment, take the egg liquid and stir evenly;

[0098] 2) High density CO 2 Sterilization treatment:

[0099] Place the homogeneous egg liquid in high-density CO 2 , the pressure is 8Mpa, the stirring speed is 100rpm and the temperature is 28°C, the sterilization treatment is 20min, the ultraviolet light and ozone are turned on, and then the treated egg liquid is aseptically packaged / aseptically filled; the primary product is obtained;

[0100] 3) Ultra-high pressure and ultrasonic co-processing:

[0101]Put the primary product in the ultrasonic treatment container, the ultrasonic power is 180W, and treat for 12 minutes; after the ultrasonic treatment is completed, put it into the ultra-high pressure sterilization container, pressurize to 150MPa, keep it for 8 minutes, and take it out after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com