Efficient coating system for textile flame-retardant layers

A technology for textiles and flame retardant layers, which is applied in the field of high-efficiency coating systems for textile flame retardant layers, can solve problems such as rubber layer fluctuations, flame retardant layer uniformity deviations, and surface rubber layer fluctuations and diffusions, so as to improve the flame retardant and waterproof effect. , Consistent uniformity, to ensure the effect of the adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

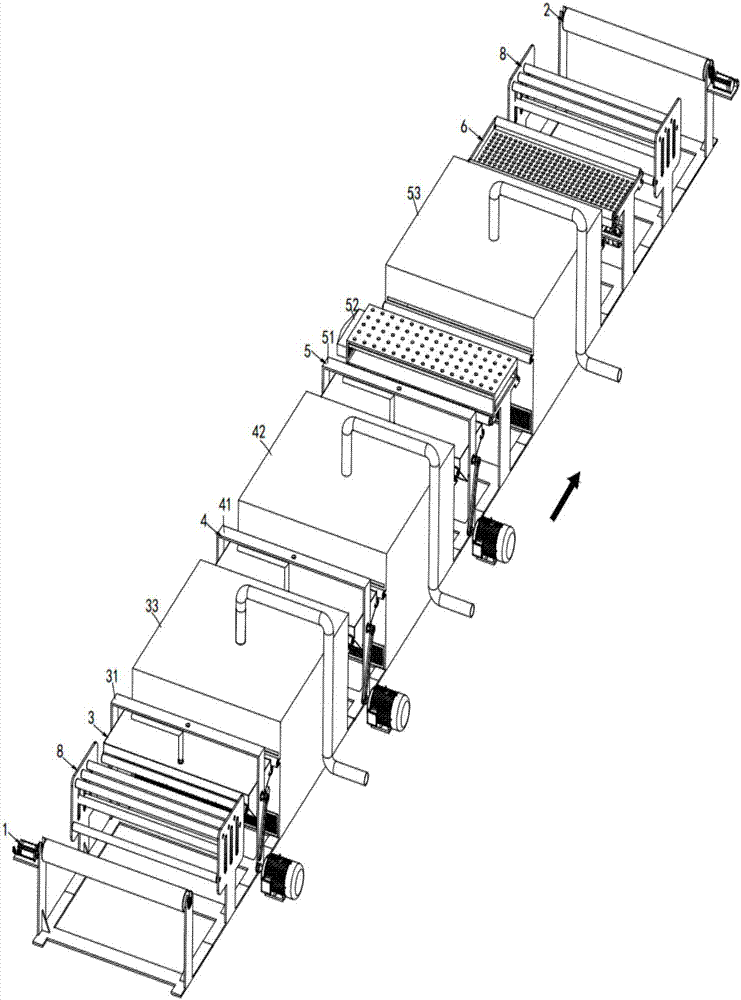

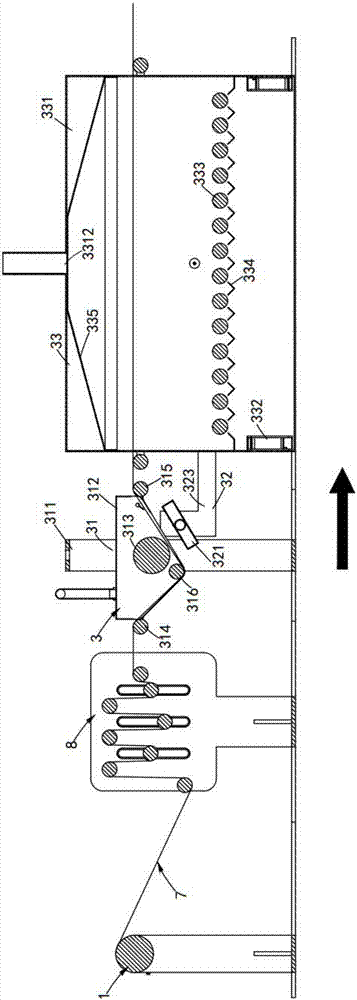

[0069] Such as figure 1 and figure 2 A high-efficiency coating system for textile flame-retardant layers includes an unwinding device 1 and a rewinding device 2, the unwinding device 1 is located on the front side of the rewinding device 2, and also includes:

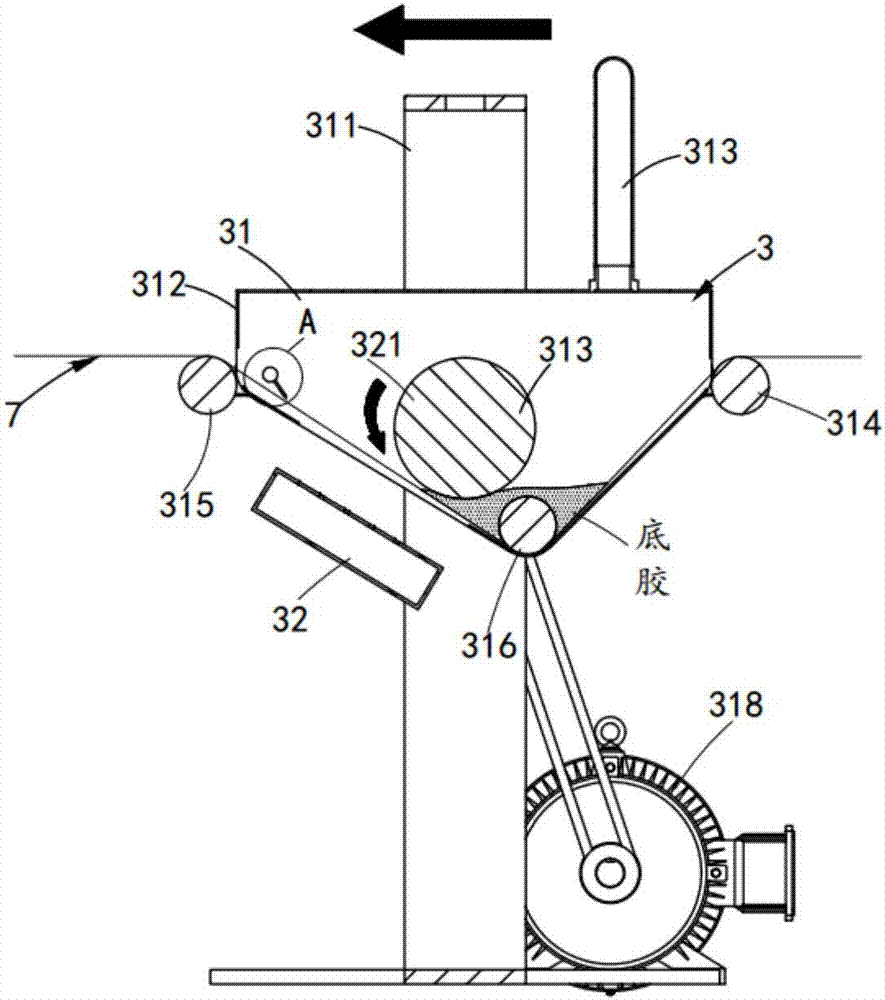

[0070] The first coating device 3, the first coating device 3 is located between the unwinding device 1 and the winding device 2, it includes a first coating unit 31, a first preheating unit 32 and a first drying unit 33, The first preheating unit 32 is located directly below the first coating unit 31, the first drying unit 33 is located at the rear side of the first coating unit 31, and the first preheating unit 32 and The first drying unit 33 is connected;

[0071] The second smearing device 4, the second smeari...

Embodiment approach

[0099] Such as Figure 9 As shown in the figure, as a preferred embodiment, the second preheating unit 52 includes:

[0100]A preheating frame 521, the top of the preheating frame 521 is provided with a preheating table 5211 arranged in a frame shape, and its width direction is arranged parallel to the conveying direction of the textile 7;

[0101] Preheating pipes 522, the preheating pipes 522 are equidistantly arranged along the width direction of the preheating rack 521, and are located on the upper part of the preheating platform 5211;

[0102] A plurality of air extractors 523 are arranged on one side of the preheating frame 521 in the longitudinal direction, and are located between the preheating pipe 522 and the textile 7 .

[0103] It should be noted that the preheating pipe 522 heats the textile 7 passing below it, so that the upper surface of the top glue layer on the textile 7 is dehydrated and condensed, and in the third drying unit 53, the textile 7 is dried. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com