Punching machine shearing photo-electric safety device

A technology for photoelectric protection and punching machines, which is applied in metal processing equipment, safety equipment, manufacturing tools, etc. It can solve problems such as the inability to reduce the vibration of photoelectric protectors, the inability to monitor the working conditions of punching machines, and the lack of monitoring cameras, etc., to achieve all-round protection. Personnel, improve protection efficiency, and facilitate the movement of the punching machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

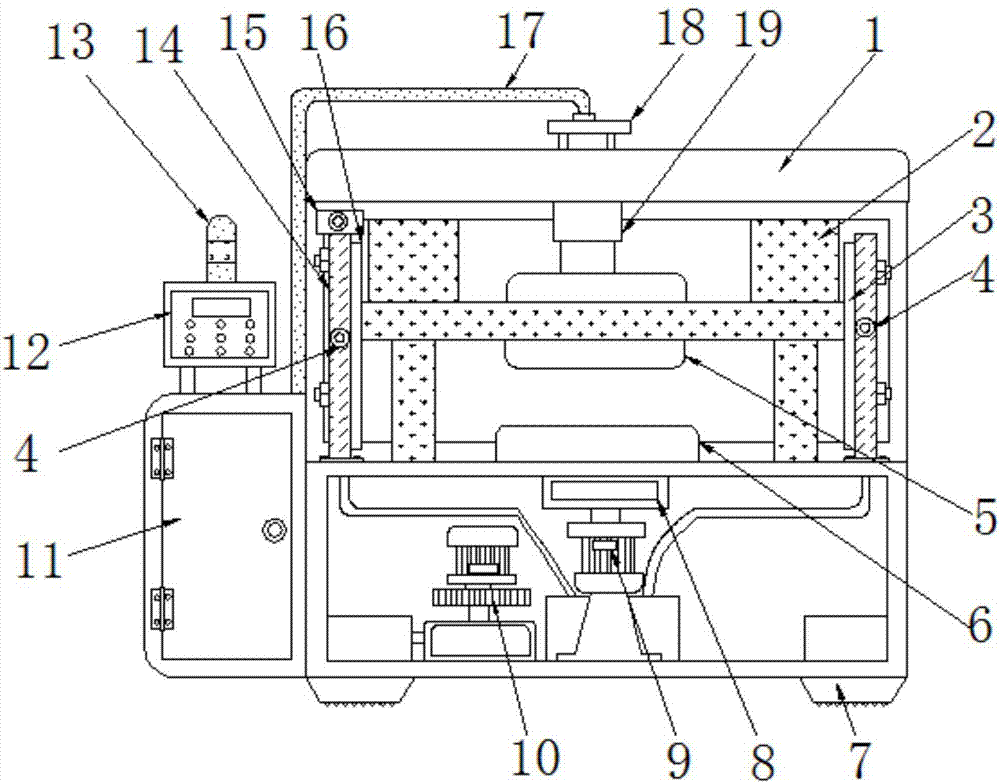

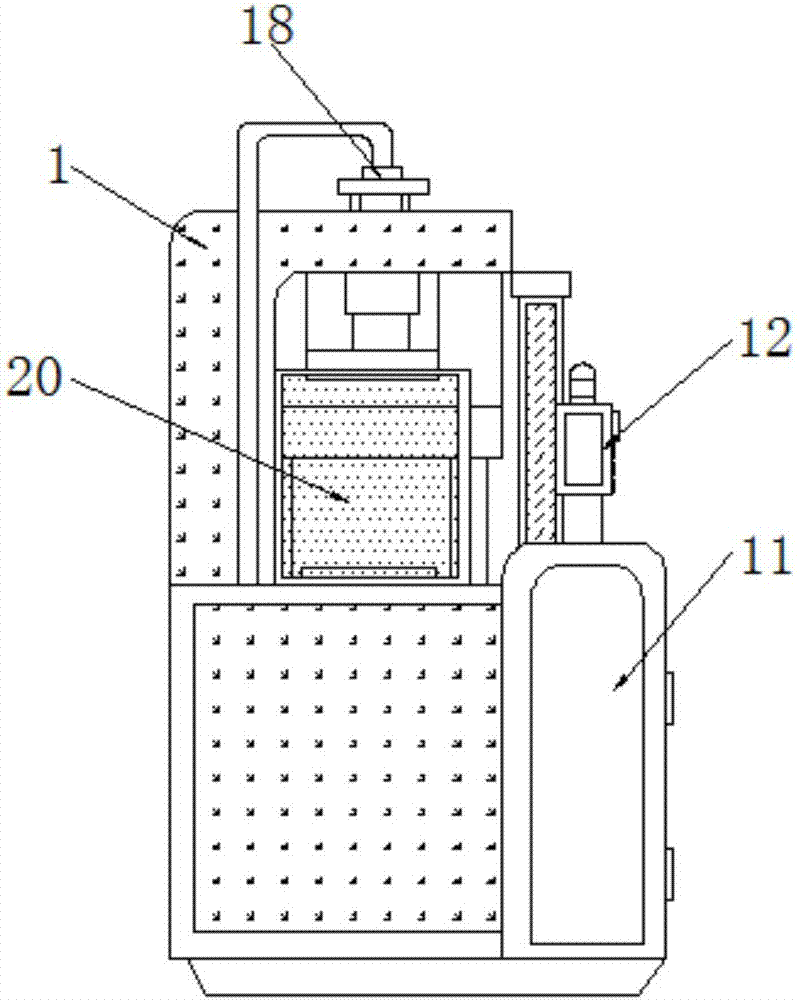

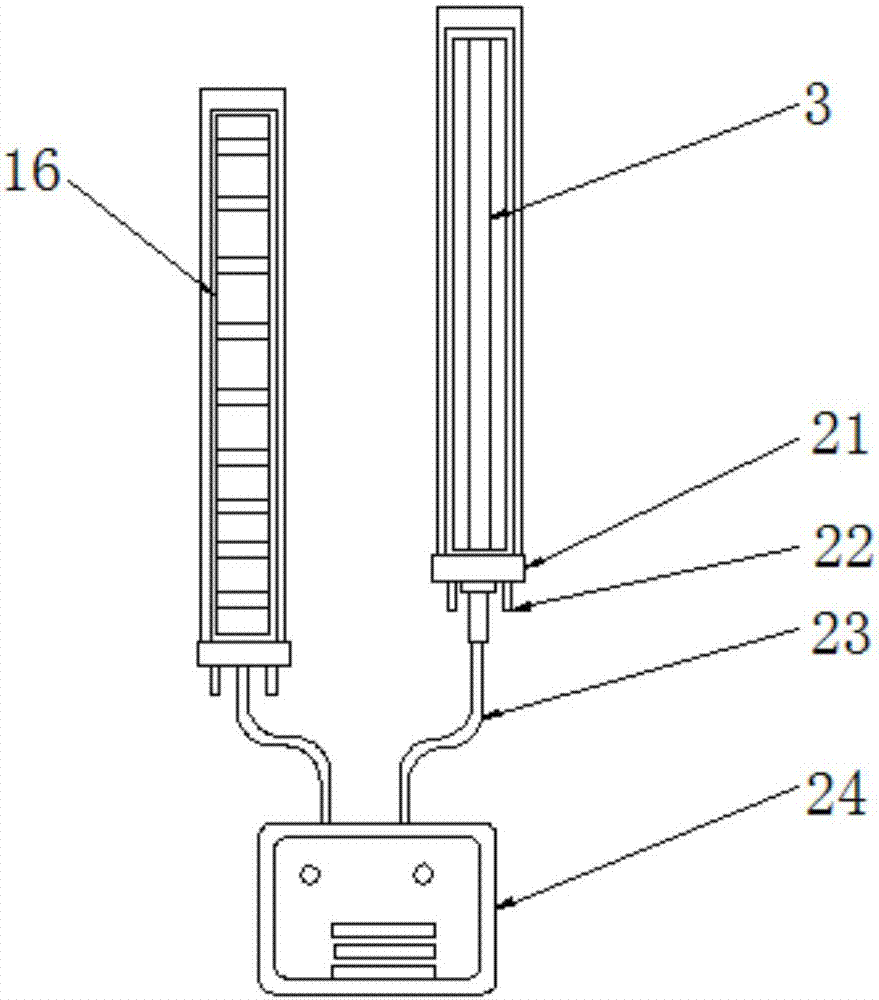

[0023] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a photoelectric protection device for punching and shearing machines, including a punching machine body 1, a guide rod 2, a light emitter 3, a distance sensor 4, a punching plate 5, a bearing plate 6, a supporting base 7, Reducer 8, servo motor 9, hydraulic pump 10, electric control box 11, control panel 12, alarm 13, mounting plate 14, monitoring camera 15, light receiver 16, oil pipeline 17, hydraulic cylinder 18, telescopic rod 19, baffle 20. Damping plate 21, spring column 22, transmission line 23, built-in controller 24 and damping wheel 25, the upper end of punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com