Inner stress reducing die injection molding technology and die

An internal stress and mold technology, applied in the field of mold and mold injection, can solve problems such as difficulty in meeting people's production requirements, large internal stress of finished products, complex process steps, etc. simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

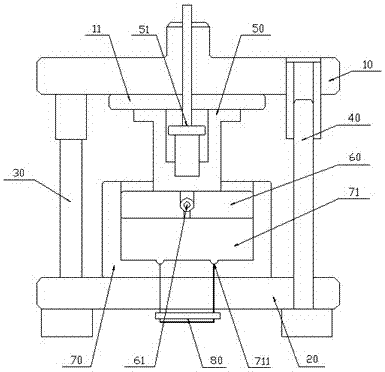

[0028] Such as figure 1 As shown, a mold for reducing internal stress according to this embodiment includes: an upper mold base 10 and a lower mold base 20. A hydraulic rod 30 is provided between the upper mold base 10 and the lower mold base 20 and used in conjunction with each other. A connecting template 11 is provided below the upper mold base 10, a mold gate 50 is provided below the connecting template 11, a movable mold 60 is provided below the mold gate 50, and the lower mold seat 20 A forming mold 70 used in cooperation with the movable mold 60 is provided thereon. The forming mold 70 is provided with a cavity 71, and the movable mold 60 is movably arranged in the cavity 71.

[0029] In a further improvement, the mold gate 50 is also provided with an elastic material device 51, the movable mold 60 is provided with an extrusion nozzle 61 for use with the mold gate 50, and the cavity 71 is provided with an overflow port 711 and the storage hopper 80 used with the overflow o...

specific Embodiment 2

[0047] Such as figure 1 As shown, a mold for reducing internal stress according to this embodiment includes: an upper mold base 10 and a lower mold base 20. A hydraulic rod 30 is provided between the upper mold base 10 and the lower mold base 20 and used in conjunction with each other. A connecting template 11 is provided below the upper mold base 10, a mold gate 50 is provided below the connecting template 11, a movable mold 60 is provided below the mold gate 50, and the lower mold seat 20 A forming mold 70 used in cooperation with the movable mold 60 is provided thereon. The forming mold 70 is provided with a cavity 71, and the movable mold 60 is movably arranged in the cavity 71.

[0048] In a further improvement, the mold gate 50 is also provided with an elastic material device 51, the movable mold 60 is provided with an extrusion nozzle 61 for use with the mold gate 50, and the cavity 71 is provided with an overflow port 711 and the storage hopper 80 used with the overflow o...

specific Embodiment 3

[0066] Such as figure 1 As shown, a mold for reducing internal stress according to this embodiment includes: an upper mold base 10 and a lower mold base 20. A hydraulic rod 30 is provided between the upper mold base 10 and the lower mold base 20 and used in conjunction with each other. A connecting template 11 is provided below the upper mold base 10, a mold gate 50 is provided below the connecting template 11, a movable mold 60 is provided below the mold gate 50, and the lower mold seat 20 A forming mold 70 used in cooperation with the movable mold 60 is provided thereon. The forming mold 70 is provided with a cavity 71, and the movable mold 60 is movably arranged in the cavity 71.

[0067] In a further improvement, the mold gate 50 is also provided with an elastic material device 51, the movable mold 60 is provided with an extrusion nozzle 61 for use with the mold gate 50, and the cavity 71 is provided with an overflow port 711 and the storage hopper 80 used with the overflow o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com