A method and equipment for mechanized feeding and harvesting of oysters on floating rafts at sea

A technology of oysters and floating rafts, applied in passenger handling equipment, cargo handling equipment, applications, etc., can solve problems such as high labor intensity, low production efficiency, and long time, and achieve the goal of reducing labor intensity, improving efficiency, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings and specific embodiments.

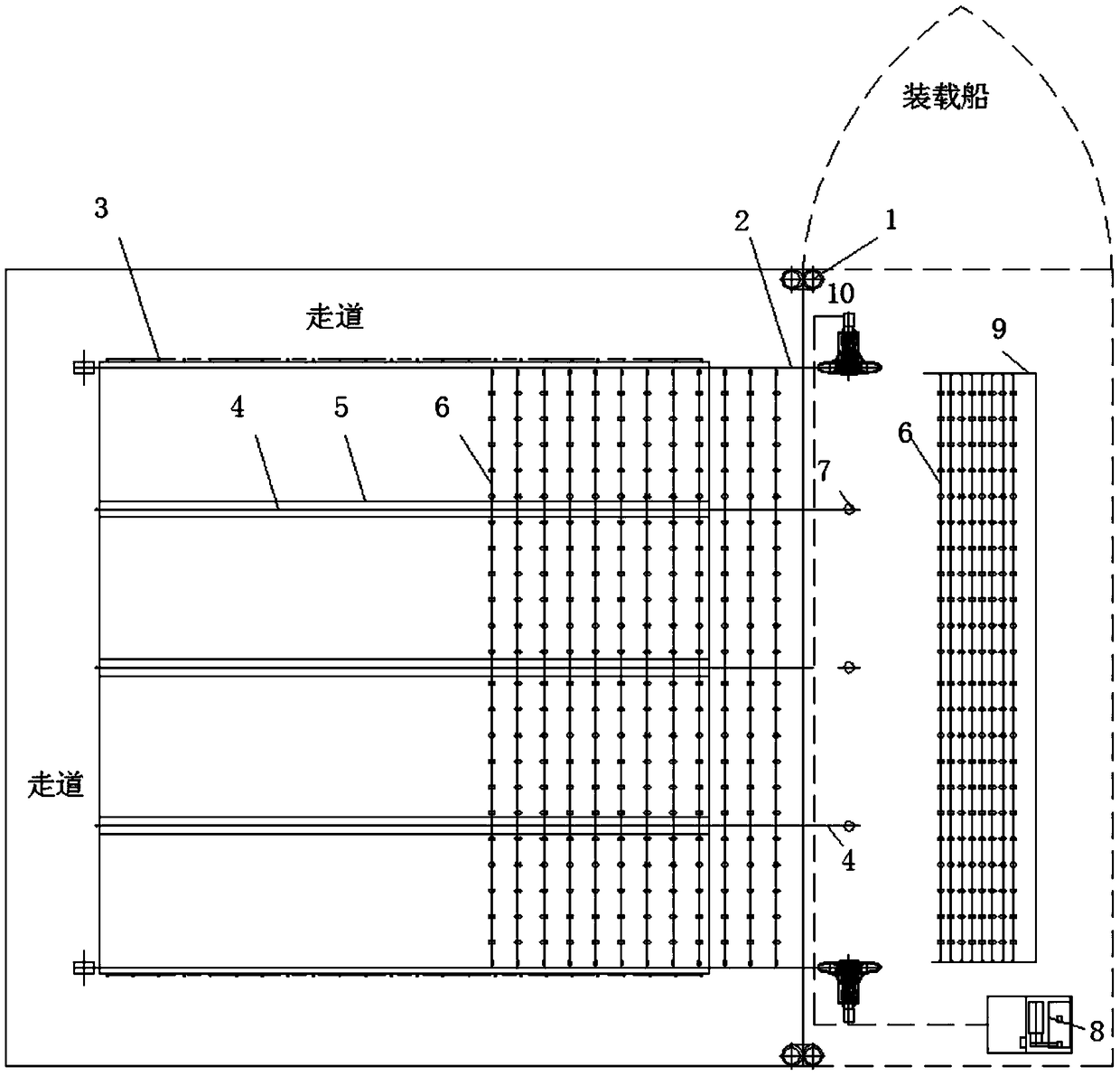

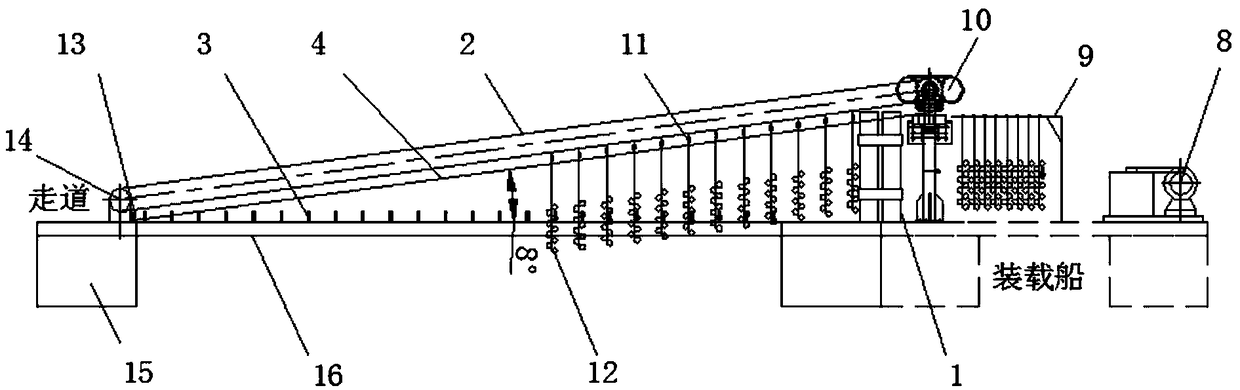

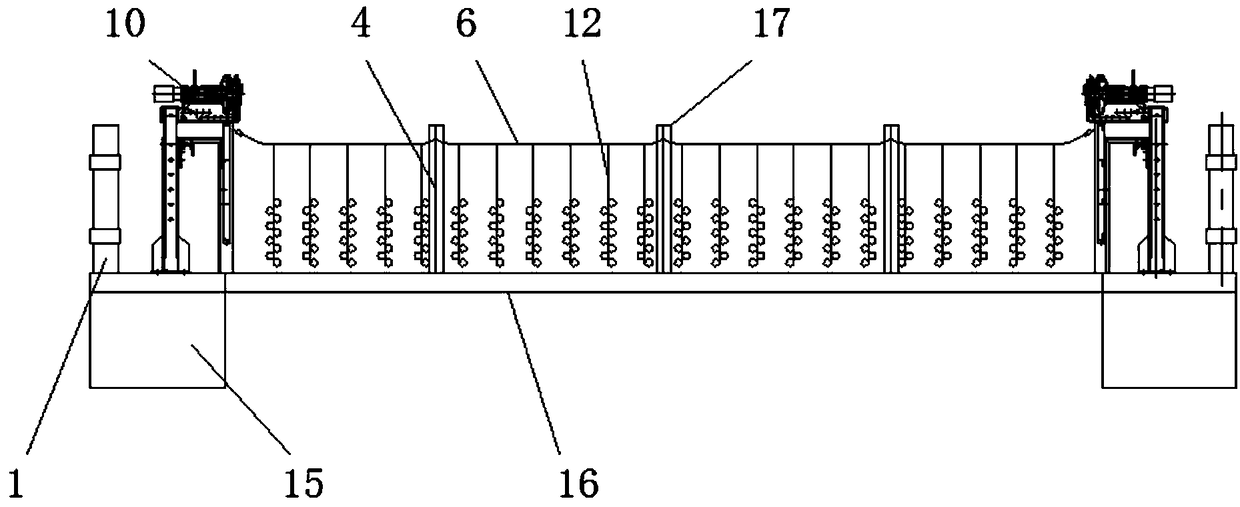

[0031] See Figure 1-3 , Standard modular marine breeding raft: The central breeding area of a single breeding raft module is 6*6m, with a frame structure around it, with buoys installed at the four corners below, and walkways on the top as working channels. The raft modules can be rigidly or flexibly connected according to the conditions of the breeding sea area, and several groups can be arranged in one word, or two rows of raft modules can be arranged side by side and then several groups.

[0032] Continue to see Figure 1-3 , There are a number of corresponding locks installed on the left and right inner side walls of the raft breeding area to fasten each breeding main rope, and the corresponding position of the front walkway of the raft is provided with a quick connection device for installing fixed pulley components before seedling throwing and harvesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com