One-person-operable power line paving device

A power line and wire laying technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve problems such as physical exertion, excessive tension of wires, and influence on line transmission safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

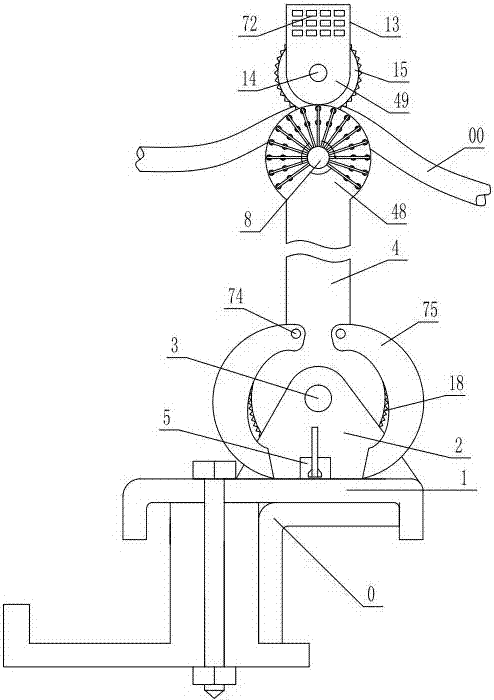

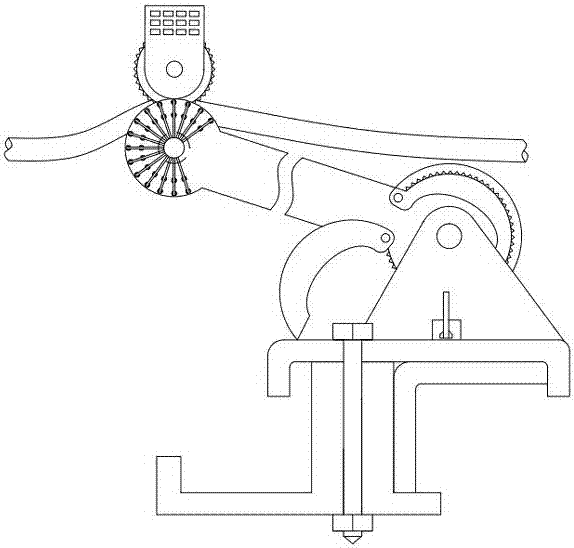

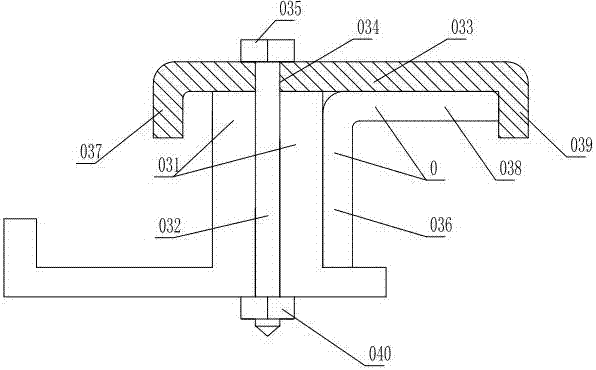

[0030]As shown in the figure, the power line laying device that can be operated by one person includes a base 1, and the bottom of the base is provided with a lower locking device that is locked and matched with the cross arm 0 of the pole. The positioning plate 031 at the bottom, the positioning plate 031 is provided with an axially horizontally extending inner screw hole 032, and also includes a clamping plate 033, the upper part of the clamping plate 033 is provided with a clamping hole 034, and the clamping hole 034 is inserted with a The inner screw hole 032 is screw-connected with the clamping bolt 035, the upper end of the clamping plate 033 is fixed with the upper hook plate 037 which is hooked and matched with the horizontal plate 036 of the cross arm 0, and the lower end of the clamping plate 033 is fixed with a hook plate 037 which is connected with the cross arm 030. The vertical plate 038 is hooked with the lower hook plate 039, and the end of the clamping bolt 035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com