Preparation of mesoporous hollow SiO2 nano-material

A technology of mesoporous silica and silica, applied in the direction of silica, silica, nanotechnology, etc., can solve the problems of excessive particle size, short reaction time, application limitations, etc., and achieve small particle size and cost. Low, low density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Using CTAC as a surfactant template to synthesize mesoporous silica nanomaterials

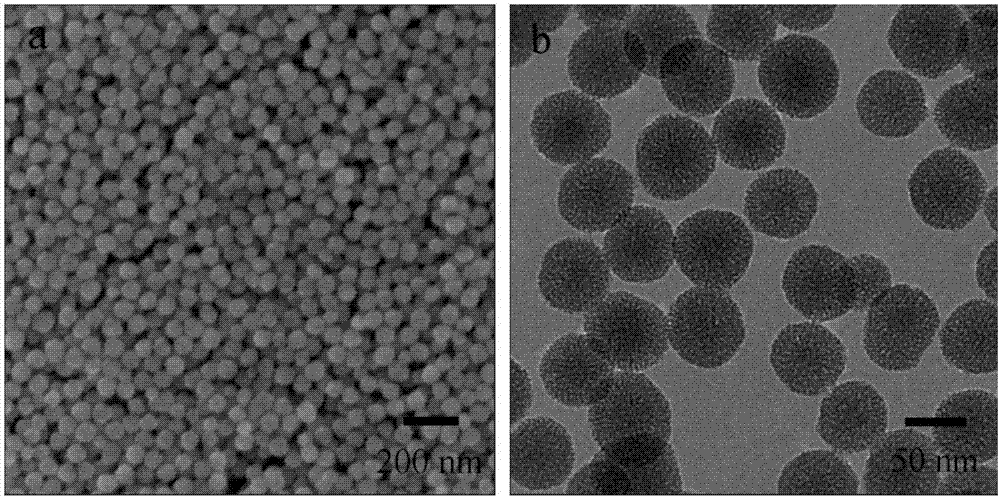

[0029] The molar ratio of water, ethanol, diethanolamine and cetyltrimethylammonium chloride CTAC aqueous solution, tetraethoxysilane TEOS, mercaptopropyltrimethoxysilane is 3.6:200:2:8:31:3.2 First, the first four materials were mixed, and the reaction was stirred at 60°C for 0.5h. Then the latter two materials were added and the reaction was continued for 3h. The SEM ( figure 1 a) and TEM image ( figure 1 b) such as figure 1 As shown, it can be seen from the figure that the particle size is uniform, the dispersibility is good, and the particle size is about 40-70nm.

[0030] (2) Using CTAC as a surfactant template and expanding the mother liquor to synthesize mesoporous hollow silica nanomaterials

[0031] Take out 5 mL of the above-prepared solution and 10 mL of TMB and place them in a 25 mL reaction kettle, mix well, and hydrothermally react at 120° C. for 1 day, and then centrifuge and...

Embodiment 2

[0033] (1) Using CTAC as a surfactant template to synthesize mesoporous silica nanomaterials

[0034] The molar ratio of water, ethanol, diethanolamine and cetyltrimethylammonium chloride CTAC aqueous solution, tetraethoxysilane TEOS, mercaptopropyltrimethoxysilane is 3.6:200:2:8:31:3.2 First, the first four materials were mixed, and the reaction was stirred at 60°C for 0.5h, and then the latter two materials were added and the reaction was continued for 3h.

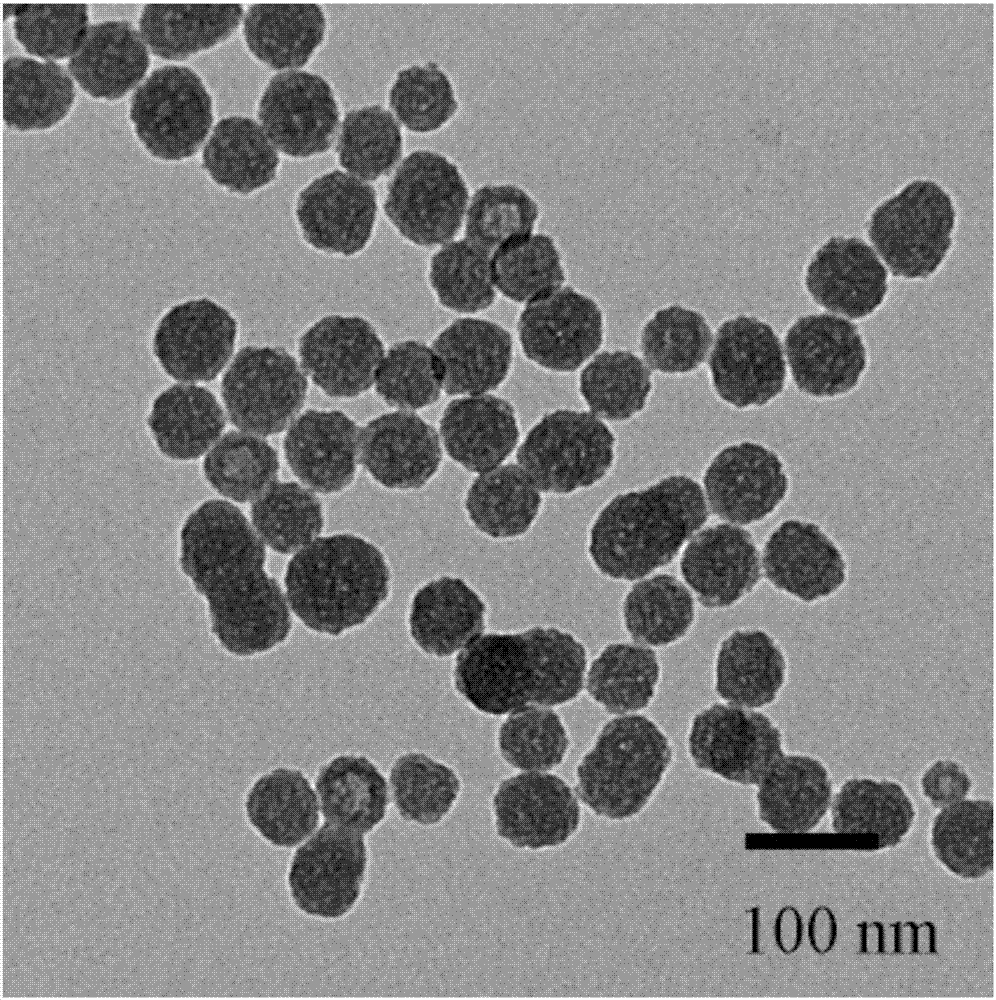

[0035] (2) Using CTAC as a surfactant template and expanding the mother liquor to synthesize mesoporous hollow silica nanomaterials

[0036] Take out 5 mL of the above-prepared solution and 15 mL of TMB and place them in a 25 mL reaction kettle, mix well, hydrothermally react at 150° C. for 2 days, and then centrifuge and wash with ethanol three times. The TEM image obtained by the test is as follows image 3 As shown, it can be seen that most of the nanoparticles are hollow.

Embodiment 3

[0038] (1) Using CTAC as a surfactant template to synthesize mesoporous silica nanomaterials

[0039] The molar ratio of water, ethanol, diethanolamine and cetyltrimethylammonium chloride CTAC aqueous solution, tetraethoxysilane TEOS, mercaptopropyltrimethoxysilane is 3.6:200:2:8:31:3.2 First, the first four materials were mixed, and the reaction was stirred at 60°C for 0.5h, and then the latter two materials were added and the reaction was continued for 3h.

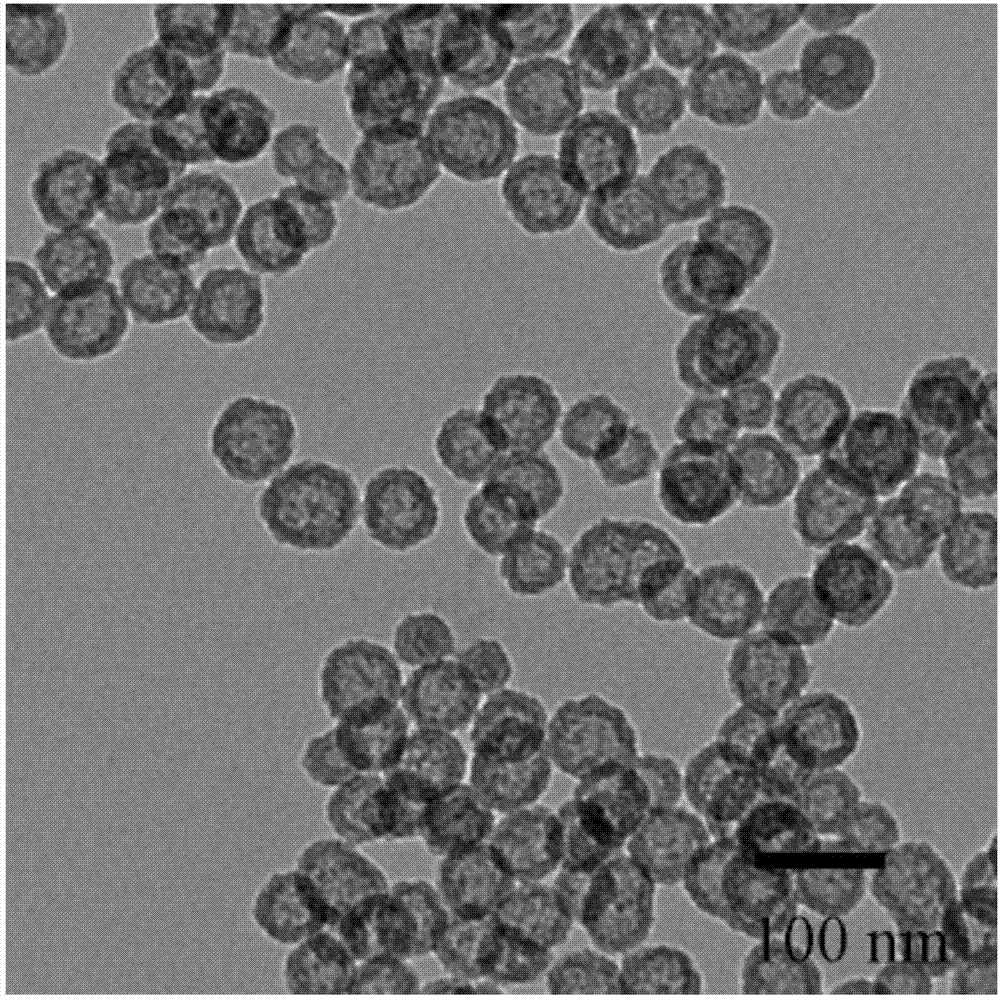

[0040] (2) Using CTAC as a surfactant template and expanding the mother liquor to synthesize mesoporous hollow silica nanomaterials

[0041] Take out 5 mL of the above-prepared solution and 5 mL of TMB and place them in a 25 mL reaction kettle, mix well, and react hydrothermally at 130°C for 3 days, and then centrifuge and wash with ethanol three times. The TEM image obtained by the test is as follows Figure 4 As shown, it can be seen that the nanoparticles are basically hollow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap