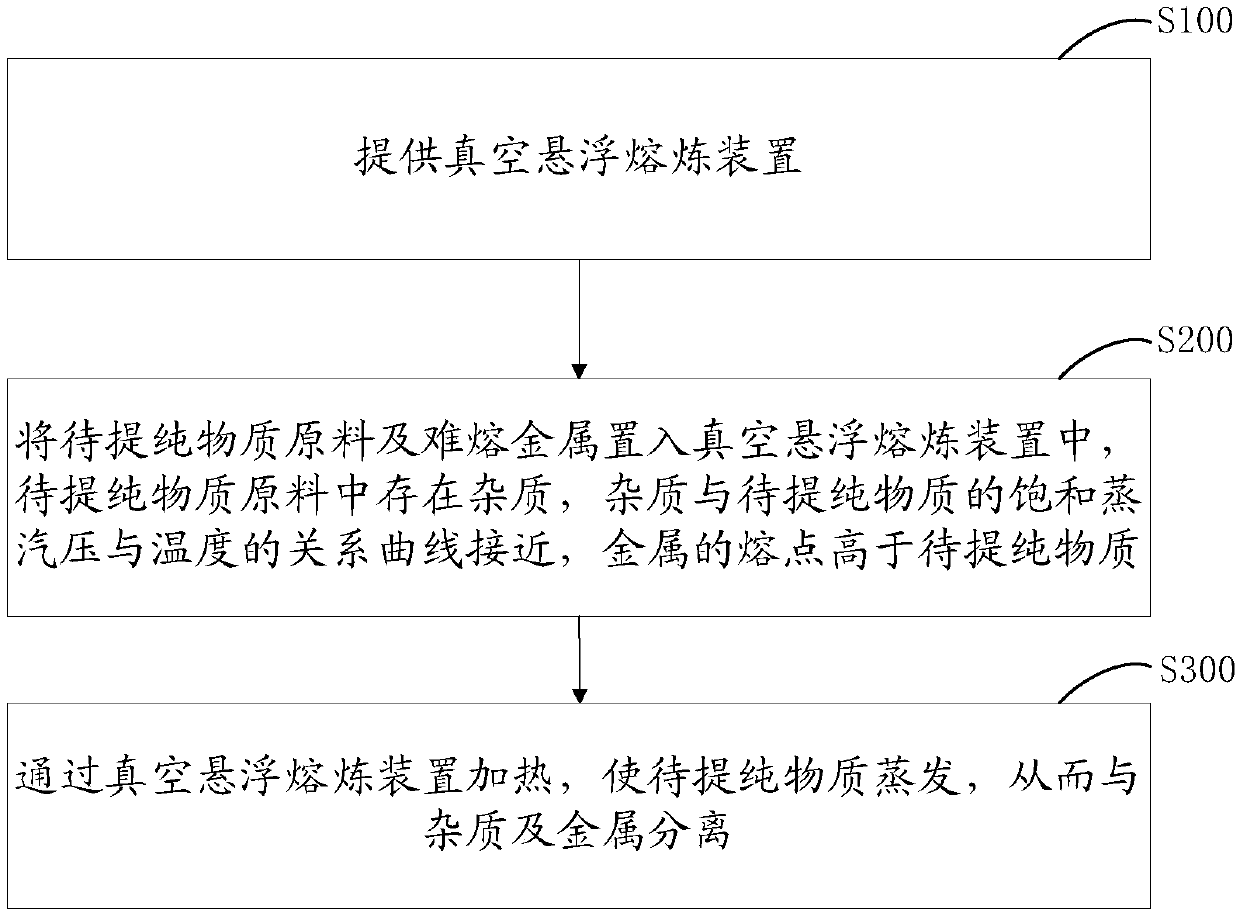

Method of Purifying Substances by Suspension Melting

A suspension smelting and material technology, applied in the field of purification, can solve the problem of insufficient material purity, and achieve the effect of increasing the saturated vapor pressure difference and improving the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

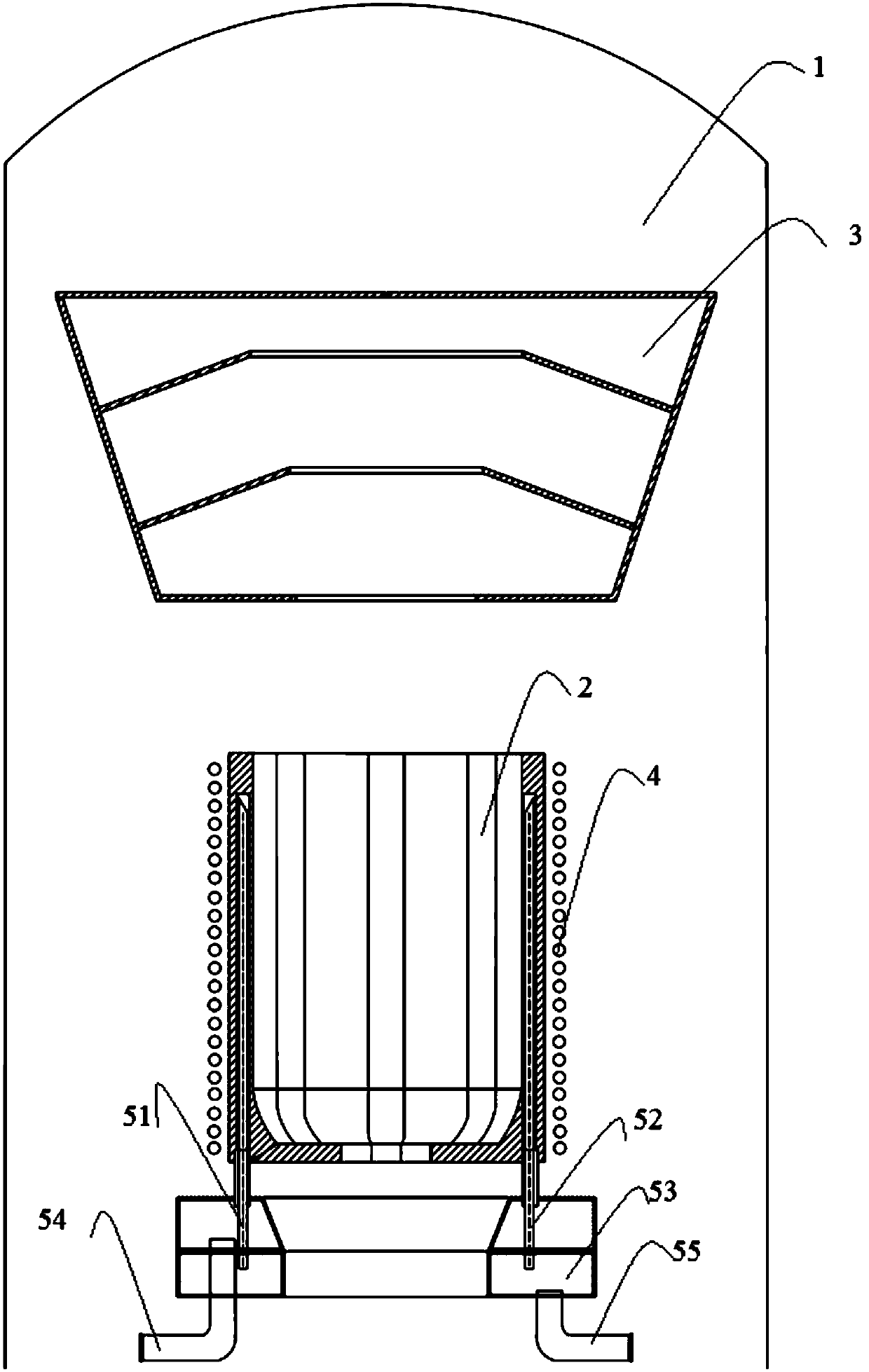

[0048] Provide industrial silicon raw materials with a purity of 99.80wt.% and refractory metal niobium. Industrial silicon raw materials include low-melting point impurities P, Al, Ga, and difficult-to-remove impurities Ti. Use acetone to clean the industrial silicon raw material and refractory metal, cut the cleaned silicon raw material and refractory metal into small pieces, place them in a copper crucible, close the furnace body, and adjust the air pressure in the furnace body. When the air pressure in the furnace reaches 2.0×10 -3 After Pa, stop vacuuming, and fill in argon with an atmospheric pressure, and then vacuumize until the pressure in the furnace reaches 2.0×10 -3 Pa. Adjust the current intensity so that the silicon raw material can be suspended or quasi-suspended in the copper crucible. Use a 30A electric current to heat the material block in the furnace, so that the temperature of the material block reaches the first temperature of 800°C, so that P, Al, Ga an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com