Waterproof breathable film and infiltrating trough for preparing breathable film

A technology of waterproof breathable membrane and waterproof layer, which is applied in fire prevention, textile material equipment configuration, building components, etc. It can solve the problems of poor breathability and waterproof effect, reduce waste and pollute the production environment, improve waterproof performance and hydrophobic effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

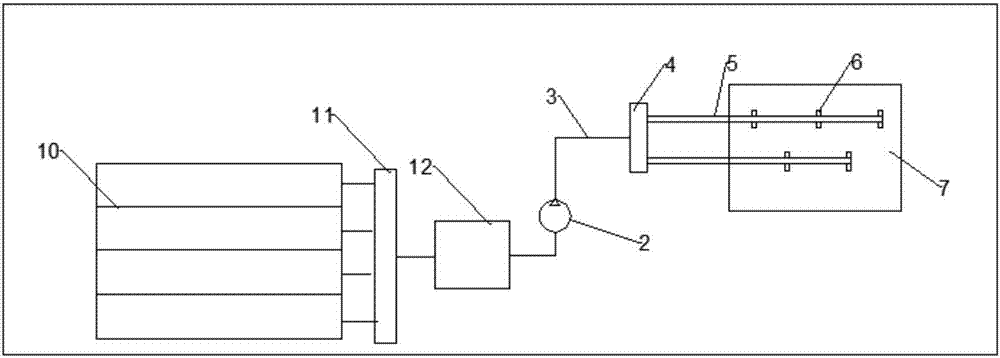

[0035] The difference between this embodiment and the first embodiment is that the composition of the infiltration liquid in the liquid storage tank 1 can be adjusted at will according to actual needs. The liquid storage tank 1 is provided with a multi-layer partition 10, which divides the liquid storage tank 1 into a plurality of storage units, each storage unit stores different components required by the infiltration liquid, and the liquid storage tank 1 is provided with a liquid pump. Aspirator 11, each storage unit is connected to the liquid aspirator 11 through pipelines, each pipeline between the storage unit and the liquid aspirator 11 is provided with a valve and a liquid flow sensor, and the valve switch is controlled by the liquid flow sensor. Set the set flow values of different liquid flow sensors according to user needs, and obtain infiltration liquids with different component weight parts according to different set values; the first delivery pipeline 3 is also p...

Embodiment 3

[0037] In this embodiment, the infiltration tank is also provided with a recovery device, the recovery device includes a liquid collector, a filter and a liquid return line, and the liquid return line is connected to the liquid collector and the second delivery pipeline 5, and part of the infiltration liquid is passed through The liquid return pipe is added to the second delivery pipe 5, and the dripping infiltration agent during the infiltration process is blocked by the baffle of the infiltration agent recovery device and transported to the infiltration agent recovery box through the infiltration agent recovery pipe, so as to achieve recycling and avoid waste Effect. The liquid collector is installed at the bottom of the infiltration tank, and a filter is arranged between the liquid collector and the infiltration tank to remove and recover impurities in the infiltration liquid, and a liquid return pump is installed on the liquid return pipeline. The bottom of the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com