Oil well intelligent control method and device

An intelligent control, oil well technology, applied in the fields of earthwork drilling, wellbore/well components, measurement, etc., can solve problems such as affecting enterprise efficiency, reducing oil pumping output, large starting current, etc., to improve safety and service life, The effect of improving oil production efficiency and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

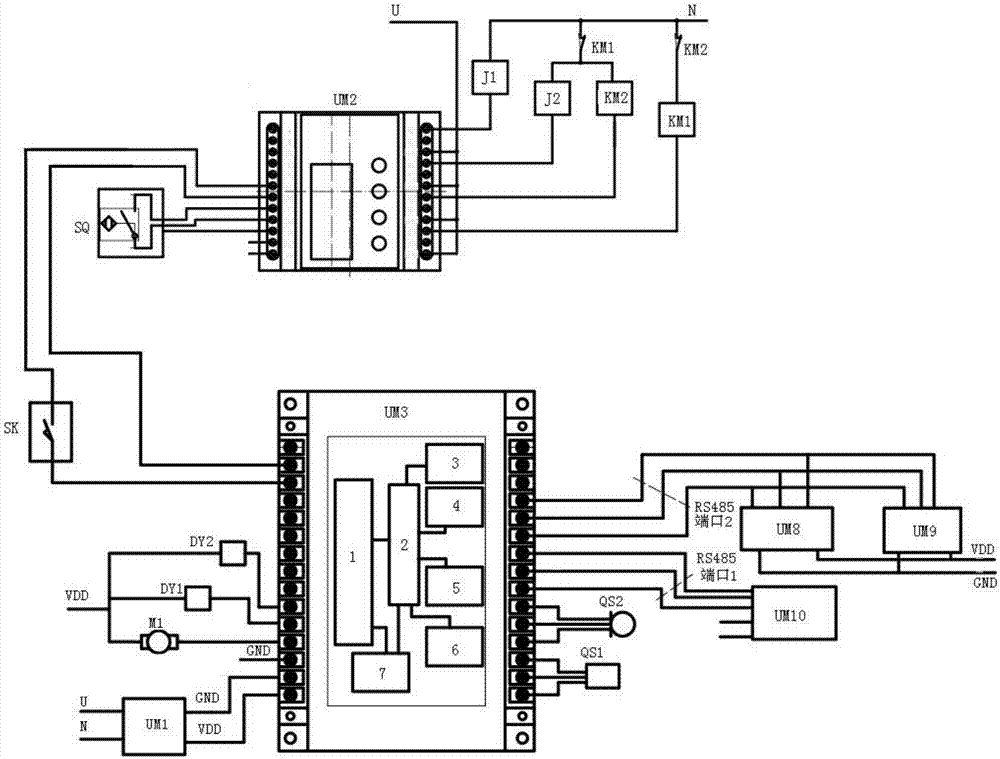

[0046] Such as figure 1 Shown: an oil well intelligent control device, including micro-sound sensor QS2, pressure transmitter QS1, wellhead sounding device and main controller UM7; micro-sound sensor QS2 and pressure transmitter QS1 are connected to the input end of the main controller UM7, The wellhead sounding device is connected to the output end of the main controller UM7.

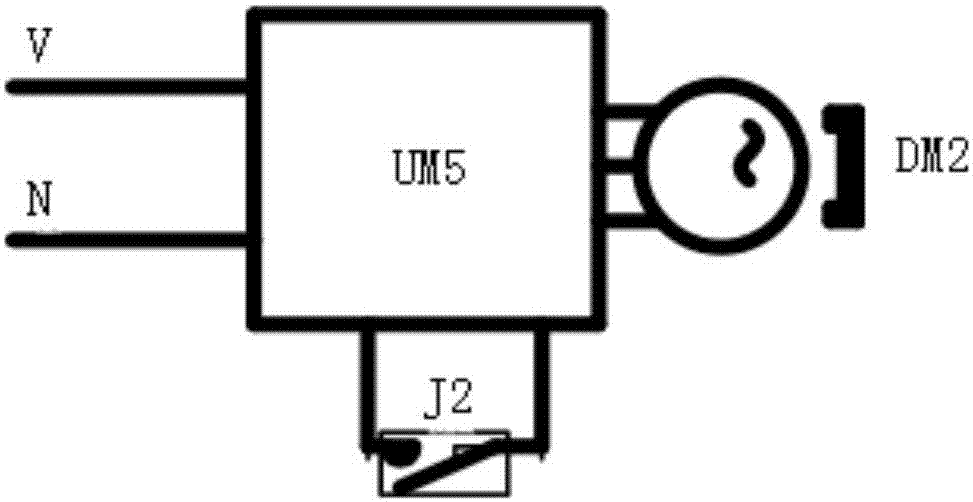

[0047] Specifically, in order to know the position of the oil level, this embodiment introduces the micro-sound sensor QS2. Its detection principle is: by making a sound at the wellhead, the sound is transmitted to the oil level along the casing, and the sound bounces and travels along the casing. The pipe returns to the wellhead, and the sound wave signal is received at the wellhead to obtain the time traveled by the sound, and the depth of the oil level fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com