Hydraulic excavator pilot hydraulic preheating system and method

A hydraulic excavator and pilot technology, applied in the direction of fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of failure of sealing elements in the valve, damage to the sealing effect, increase maintenance costs, etc., to reduce The effect of energy consumption, prolonging the life of the whole machine, and reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

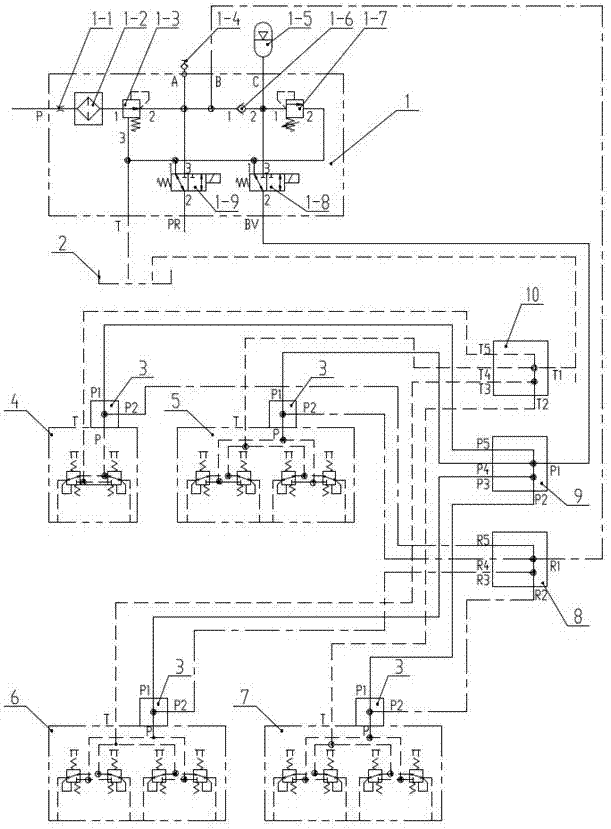

[0020] Such as figure 1 As shown, a pilot hydraulic preheating system for a hydraulic excavator includes a pilot oil source block 1, a hydraulic oil tank 2, a bulldozing pilot valve 4, a right handle pilot valve 5, a foot pilot valve 6, a left handle pilot valve 7, a preheating Diverter block 8, oil supply diverter block 9, oil return diverter block 10; the oil inlets of bulldozing pilot valve 4, right handle pilot valve 5, foot pilot valve 6 and left handle pilot valve 7 are provided with a three-way 3 .

[0021] Pilot oil source block 1 includes orifice 1-1, filter 1-2, pressure reducing valve 1-3, pressure measuring joint 1-4, accumulator 1-5, check valve 1-6, safety overflow Valves 1-7, safety solenoid valves 1-8 and traveling high and low speed solenoid valves 1-9; Pilot oil source block 1 is provided with P port, A port, B port, C p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com