Solid-liquid mixing material drying device

A drying device and solid-liquid mixing technology, which is applied in the direction of drying solid materials, heating devices, dry cargo handling, etc., can solve the problems of uneven drying quality, inconvenient wear and tear of seals, large stirring force, etc., and achieve strong adaptability of the device , Loading and unloading are convenient and labor-saving, and the effect of stirring is labor-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The invention provides a solid-liquid mixture material drying device;

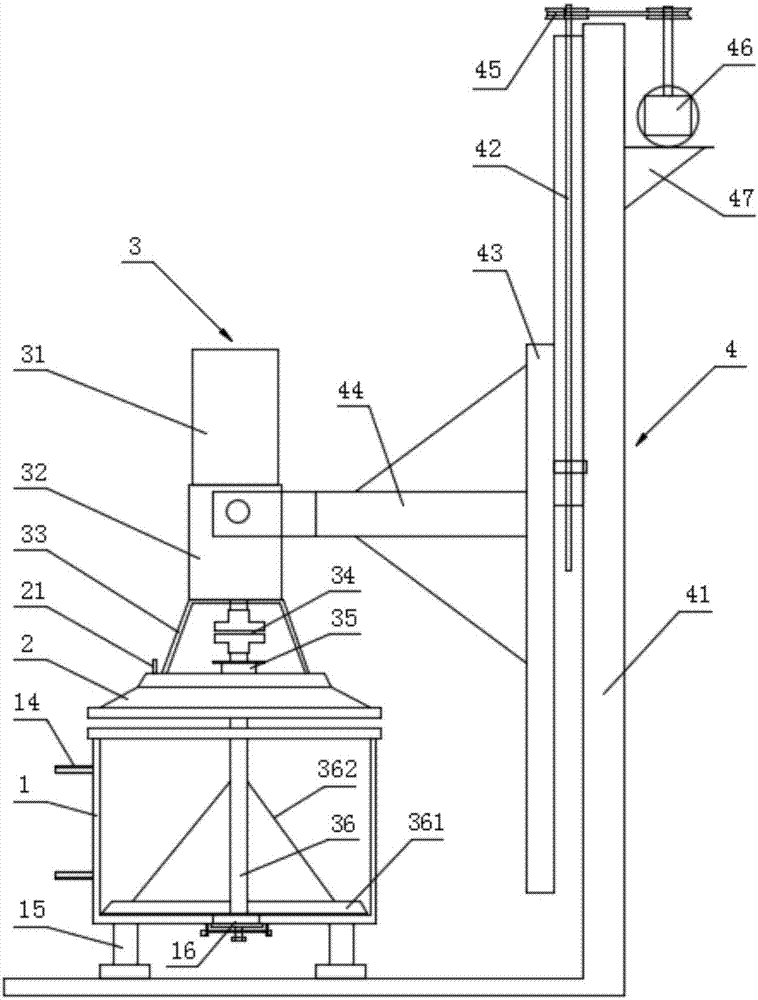

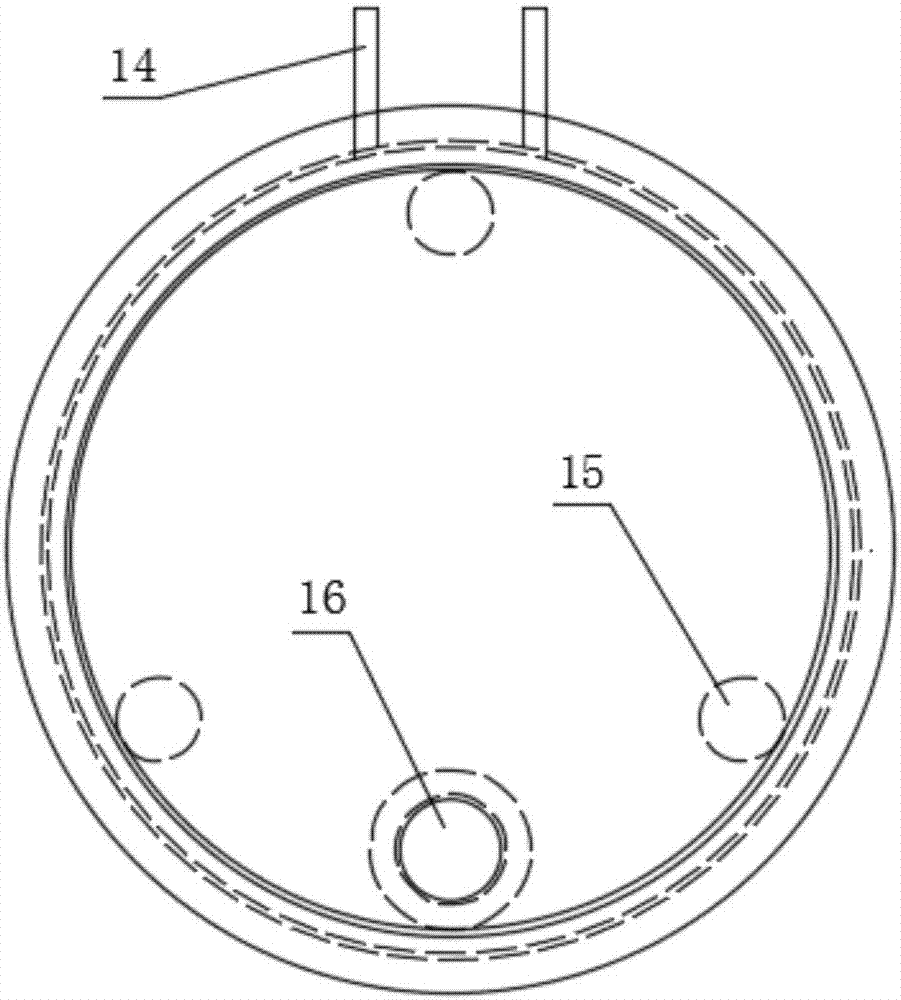

[0032] Such as Figure 1-Figure 5 As shown, the solid-liquid mixture drying device in this embodiment includes a cylinder body 1 and a cylinder cover 2, the bottom of the cylinder body 1 is provided with a discharge port 16, and the cylinder body 1 is provided with a vertical stirring mechanism 3. The canister cover 2 is connected with a lifting mechanism 4 that can move the canister cover 2 up and down, and the canister cover 2 is also provided with a medium recovery port 21 .

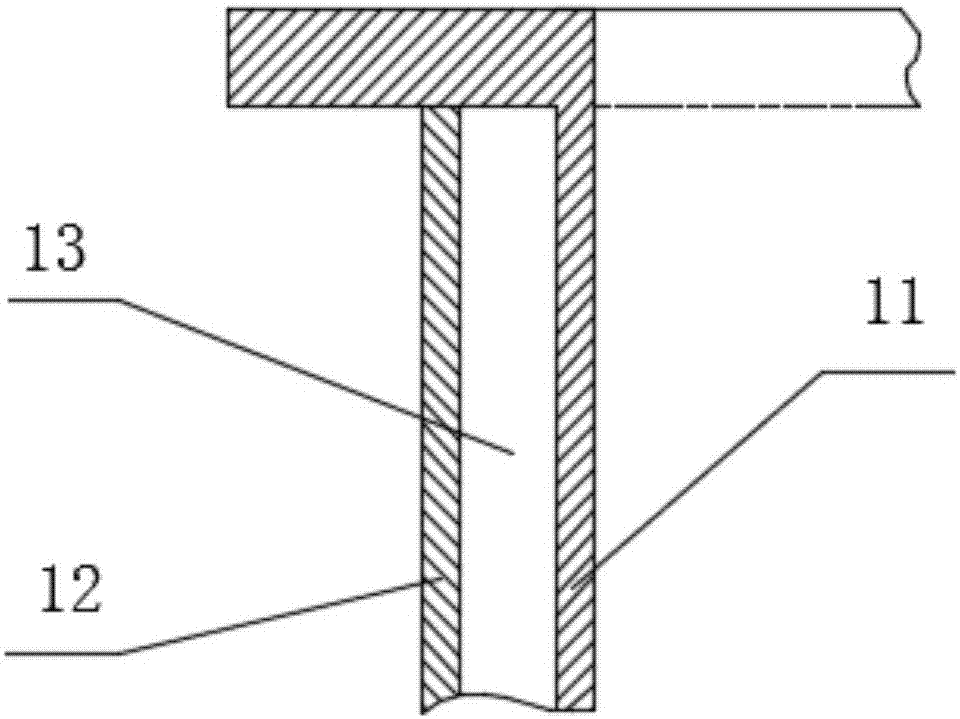

[0033] In this embodiment, the cylinder body 1 includes an inner cylinder 11 and an outer cylinder 12, and a hollow jacket 13 is formed between the inner cylinder 11 and the outer cylinder 12, and the hollow jacket can withstand a pressure of 0.3 MPa without deformation, so The outer cylinder 12 is provided with a pipe 14 communicating with the hollow jacket 13, and a heating medium or a cooling medium can be passed into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com