Online mixing-feeding system

A technology of feeding system and dynamic mixer, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of viscosity increase, waste, increase production cost of enterprises, etc., to achieve novel technology, reduce production cost, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

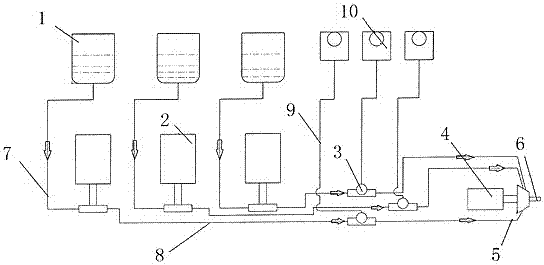

[0008] The embodiment will be described in detail in conjunction with the above drawings. A precision gear metering pump 2, a mass flow meter 3 and a dynamic mixer 4 are arranged in sequence on the liquid tank 1. There are at least two precision gear metering pumps, and each precision gear metering pump The inlet of the metering pump is connected with a feed pipe, and the feed pipe 7 is connected with the raw material liquid tank, and the outlet of the precision gear metering pump is connected with the inlet of the mass flow meter 3 through the delivery pipeline 8. The flowmeter is connected to the controller, and the controller is connected to the control display 10 through a special cable 9 to form a closed-loop control. The control display is fixed on the wall above the mass flowmeter, and the outlet of the mass flowmeter is connected to the dynamic flow through the pipeline. The liquid inlet 5 on the mixer is connected, and the liquid outlet 6 on the dynamic mixer is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com