Light guide plate dust-sticking device

A light guide plate and dust-sticking technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of time-consuming and labor-intensive dust cleaning, reduce the dust-sticking effect of the light guide plate, and unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

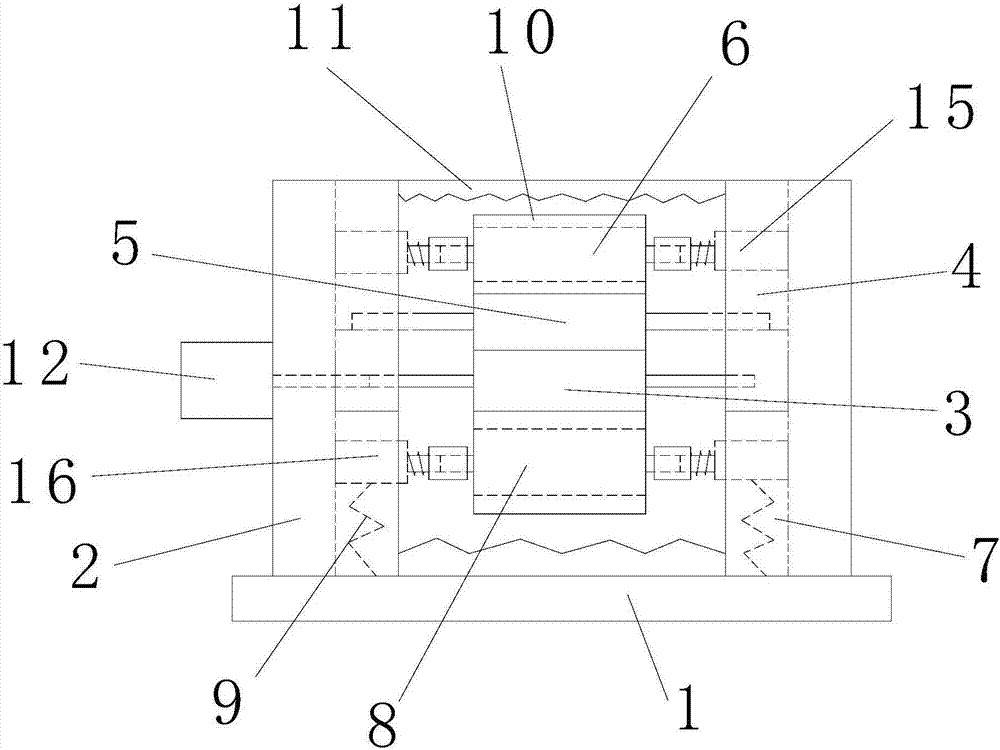

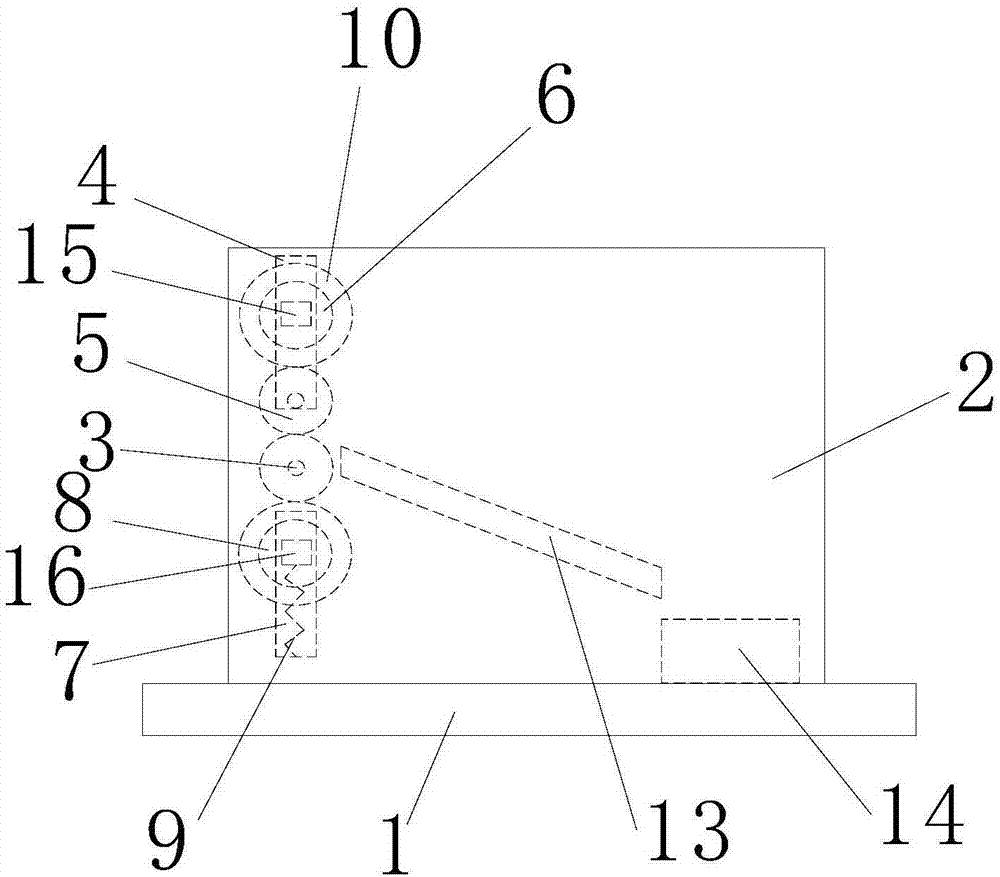

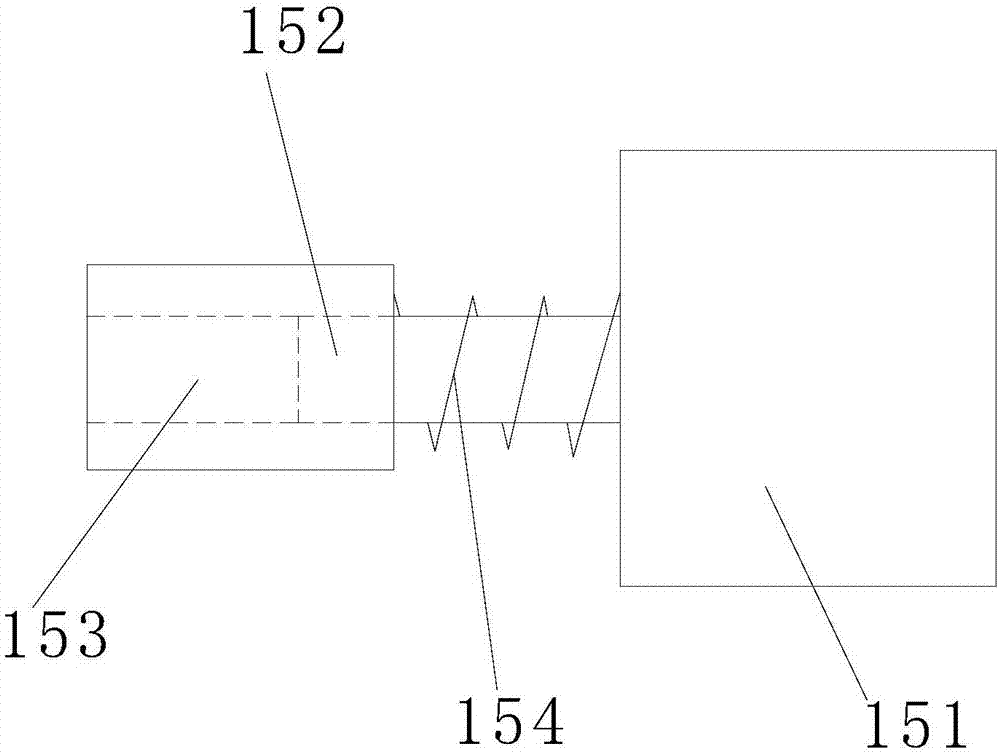

[0018] See figure 1 , 2 , 3. A light guide plate dust sticking equipment of the present invention includes a base 1, a side plate 2, a first sticking roller 3, a first chute 4, a second sticking roller 5, a third sticking roller 6, a second The chute 7, the fourth sticky roller 8, the first spring 9, the sticky tape 10, the serrated bar 11, the motor 12, the sliding plate 13, the material receiving box 14, the first disassembly assembly 15 and the second disassembly assembly 16, the The upper part of the base 1 is fixedly provided with two vertically arranged side plates 2 parallel to each other, and a first dust-sticking roller 3 arranged horizontally and perpendicular to the side plate 2 is rotated between the side plates 2. On the opposite side of 2 and directly above the connecting part of the first sticking roller 3 and the side plate 2, a first chute 4 is arranged vertically correspondingly, and directly above the first sticking roller 3 is rotatably arranged The second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com