Weather resistant modified bitumen waterproof membrane

A technology of modified asphalt and waterproof membranes, which is applied in the field of chemical materials for construction, can solve the problems of affecting air environment quality and personal safety, affecting the service life of waterproof functional materials, and various performances cannot be maintained for a long time, so as to improve the aging speed Fast, good construction performance, good creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of weather resistance modified asphalt

[0026] Add 20g of 90# petroleum asphalt to 80g of molten lake asphalt, heat up to 185°C, add 12g of thermoplastic elastomer SBS4402, heat up to 185°C-195°C, start colloidal grinding, homogenization time is 2 hours; add 20g For light calcium carbonate, keep the temperature at 180°C to 185°C. After stirring for 1 hour, add 0.10g of ultraviolet absorber and stir for 0.5h to make weather-resistant modified asphalt for later use.

[0027] Preparation of heat-melt modified asphalt

[0028] Heat 100g of 200# liquid petroleum asphalt to 170°C, add 18g of thermoplastic elastomer SBS4402 and 6g of plastomer APAO, heat up to 185°C-195°C, start colloidal grinding, and homogenize for 2 hours; add 50g of light Calcium carbonate, the temperature is kept at 180 ℃ ~ 185 ℃ and stirred for 1 hour, and then it is made into a hot-melt modified asphalt for later use.

Embodiment 2

[0030] Preparation of weather resistance modified asphalt

[0031] Add 30g of 90# petroleum asphalt to 70g of molten lake asphalt, heat up to 185°C, add 15g of thermoplastic elastomer SBS4402, heat up to 185°C-195°C, start colloidal grinding, homogenization time is 2 hours; add 30g For light calcium carbonate, keep the temperature at 180°C to 185°C. After stirring for 1 hour, add 0.10g of ultraviolet absorber and stir for 0.5h to make weather-resistant modified asphalt for later use.

[0032] Preparation of heat-melt modified asphalt

[0033] Heat 100g of 200# liquid petroleum asphalt to 170°C, add 18g of thermoplastic elastomer SBS4402 and 6g of plastomer APAO, heat up to 185°C-195°C, start colloidal grinding, and homogenize for 2 hours; add 50g of light Calcium carbonate, the temperature is kept at 180 ℃ ~ 185 ℃ and stirred for 1 hour, and then it is made into a hot-melt modified asphalt for later use.

Embodiment 3

[0035] Preparation of weather resistance modified asphalt

[0036] Add 50g of 90# petroleum asphalt to 50g of molten lake asphalt, heat up to 185°C, add 18g of thermoplastic elastomer SBS4402, heat up to 185°C-195°C, start colloidal grinding, homogenization time is 2 hours; add 40g For light calcium carbonate, keep the temperature at 180°C to 185°C. After stirring for 1 hour, add 0.10g of ultraviolet absorber and stir for 0.5h to make weather-resistant modified asphalt for later use.

[0037] Preparation of heat-melt modified asphalt

[0038] Heat 100g of 200# liquid petroleum asphalt to 170°C, add 18g of thermoplastic elastomer SBS4402 and 6g of plastomer APAO, heat up to 185°C-195°C, start colloidal grinding, and homogenize for 2 hours; add 50g of light Calcium carbonate, the temperature is kept at 180 ℃ ~ 185 ℃ and stirred for 1 hour, and then it is made into a hot-melt modified asphalt for later use.

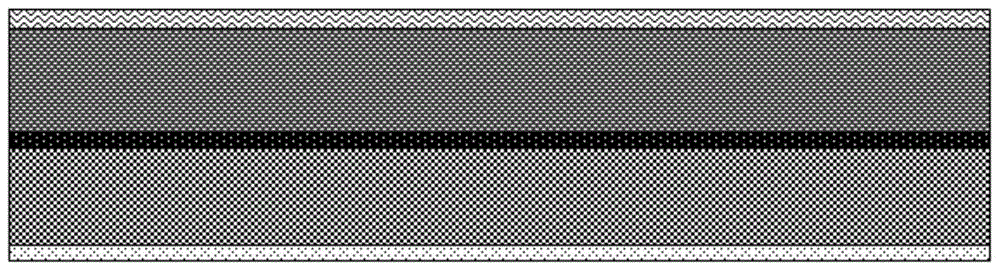

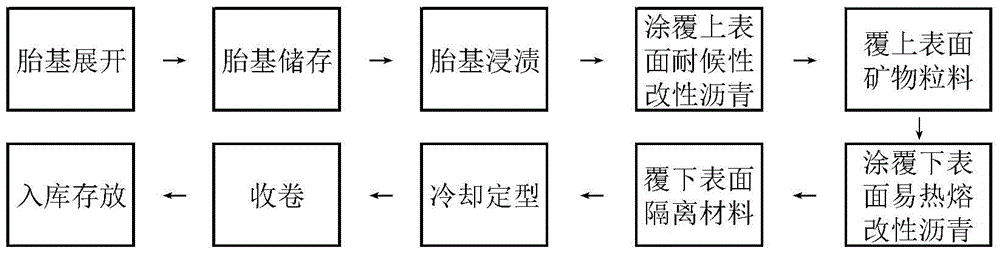

[0039] Based on the two specifications of modified asphalt prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com