Pre-laid polymer waterproof coiled material and preparation method thereof

A technology of polymer waterproofing and coiled materials, which is applied in shaft equipment, mining equipment, earthwork drilling and mining, etc. It can solve the problems of poor weather resistance and easy aging, and achieve enhanced full-stick effect, improved environmental protection, and reduced sand damage. The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

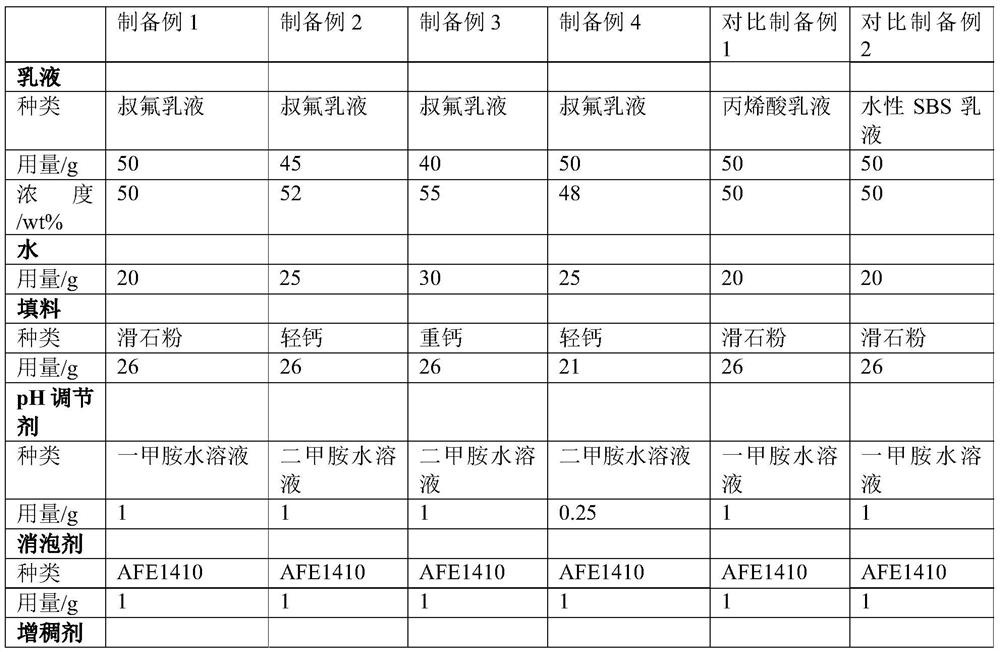

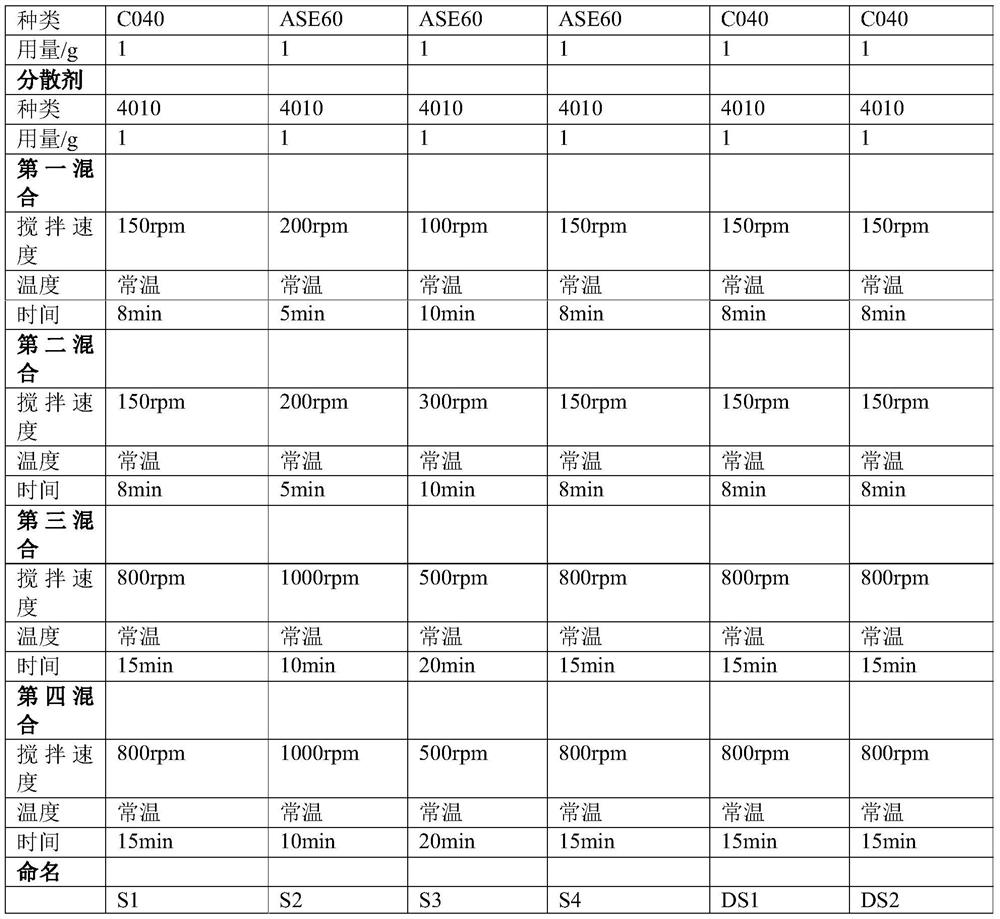

preparation example Construction

[0051] The present invention has no special requirements on the preparation method of the water-based fluorocarbon coating, and can be prepared by using existing methods. Exemplarily, the present invention provides a particularly preferred preparation method of the water-based fluorocarbon coating. The method includes the following steps:

[0052] (1) water and thickener are mixed for the first time to obtain the first mixture;

[0053] (II) performing a second mixture of the first mixture and a pH regulator to obtain a second mixture;

[0054] (III) mixing the second mixture, tertiary fluorine emulsion, filler and defoamer for the third time to obtain the third mixture;

[0055] (IV) performing a fourth mixing of the third mixture with a dispersant.

[0056] According to a particularly preferred embodiment, in step (I), the conditions for the first mixing at least meet: a stirring speed of 100-200 rpm, a temperature of 5-35° C., and a time of 5-10 min.

[0057] According to...

preparation example 1

[0085] This preparation example is used to illustrate that the water-based fluorocarbon coating according to the present invention is prepared according to the formula and process parameters in Table 1, and the water-based fluorocarbon coating is prepared as follows.

[0086] The method for preparing the waterborne fluorocarbon coating may further comprise the steps:

[0087] (1) Stir the water and the thickener at 150 rpm for 8 minutes at normal temperature to obtain the first mixture;

[0088] (2) Stir the first mixture obtained above and the pH regulator at 150 rpm for 8 minutes at normal temperature to obtain the second mixture;

[0089] (3) Stir the second mixture, tertiary fluorine emulsion, filler and defoamer obtained above at 800 rpm for 15 minutes at room temperature to obtain a third mixture;

[0090] (4) At room temperature, the third mixture obtained above and the dispersant were stirred at 800 rpm for 15 minutes to obtain the water-based fluorocarbon coating S1....

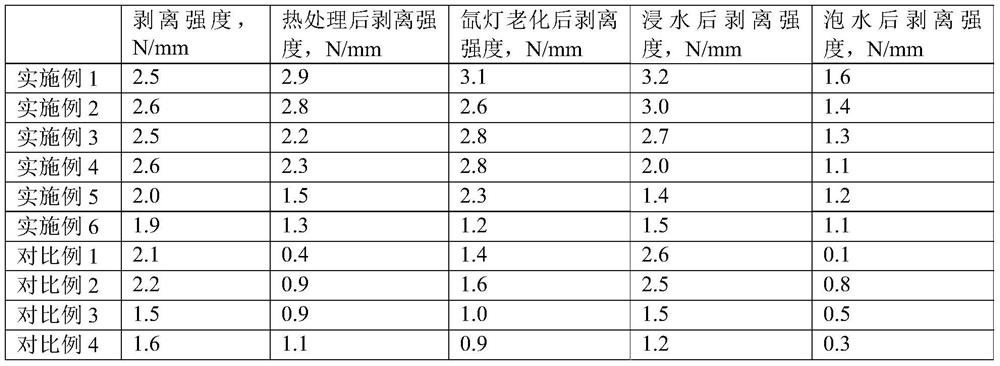

Embodiment 1

[0096] This example provides a method for preparing a pre-laid polymer waterproof membrane, using low-pressure polyethylene as a carrier, scraping hot-melt pressure-sensitive adhesive on the carrier to form an adhesive layer, and spraying the adhesive layer prepared in Preparation Example 1 on the adhesive layer Water-based fluorocarbon coating forms a protective layer, and then bakes at 100°C for 3 minutes to cure the protective layer to obtain a pre-laid polymer waterproof membrane A1;

[0097] Wherein, the thickness ratio of the carrier, the adhesive layer, and the protective layer is 1:0.3:0.12; the thickness of the protective layer is 1.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com