A kind of oxidized constant viscosity agent and its constant viscosity natural rubber product and preparation method

A kind of natural rubber and oxidation technology, applied in the field of preparation of oxidized constant viscosity natural rubber, can solve the problems of constant viscosity natural rubber losing constant viscosity effect, 2-mercaptobenzothiazole is difficult to dissolve, endangering the health of workers, etc. The effect of good constant viscosity, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The second aspect of the present invention relates to a preparation method of oxidized constant viscosity natural rubber, the steps of the preparation method are as follows:

[0024] 1) Dissolving the above-mentioned oxidized constant viscosity agent completely in the aqueous solution to prepare a constant viscosity agent solution for subsequent use;

[0025] 2) Take an appropriate amount of fresh latex, add a constant viscosity agent solution during stirring, and after the solution is completely solidified, the curd is matured for 6h-8h, dehydrated, washed, and dried to obtain a constant viscosity natural rubber.

[0026] As an embodiment of the present invention, in the step 1), the mass concentration of the constant viscosity agent solution is 5-20%; more preferably 5-10%; more preferably 10%.

[0027] As an embodiment of the present invention, in the step 2), 100ppm-400ppm of oxidized constant viscosity agent is added to every 1000g of fresh latex.

[0028] As an e...

Embodiment approach

[0029] As an embodiment of the present invention, in the step 2), the stirring speed is 100-200r / min.

[0030] The coagulation method in the present invention can be any method known to those skilled in the art such as acid coagulation, static coagulation or microbial coagulation, and static coagulation is mainly used in the present invention.

[0031] Constant viscosity

[0032] Mooney viscosity is an important index to measure the processing and use performance of natural rubber (NR), because the change of Mooney viscosity of NR during storage has a great impact on its use. NR with constant viscosity is beneficial to simplify the production process of the product, improve the level of automation control, maintain the consistency of product performance, shorten the plasticating time of raw rubber, and reduce energy consumption. Therefore, the production of NR with constant viscosity is welcomed by users. At present, the preparation of constant viscosity NR (CVNR) is usuall...

Embodiment 1

[0043] This embodiment provides a preparation method of oxidized constant viscosity natural rubber, the steps of the preparation method are as follows:

[0044] (1) 4g sodium hypochlorite and 6g hydrogen peroxide mixture are dissolved in aqueous solution, continue to stir until mixture dissolves completely, be mixed with the constant viscosity agent solution that concentration is 10wt%;

[0045] (2) Take 1000g of fresh latex and add 350ppm (calculated by latex weight) constant viscosity agent to solidify, dehydrate, wash, and dry to obtain constant viscosity natural rubber; the stirring speed is 200r / min, and the curd is cured for 6.5h.

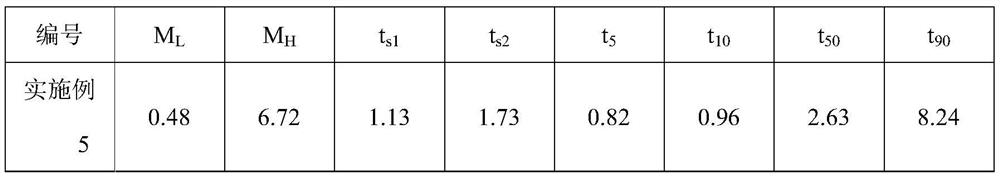

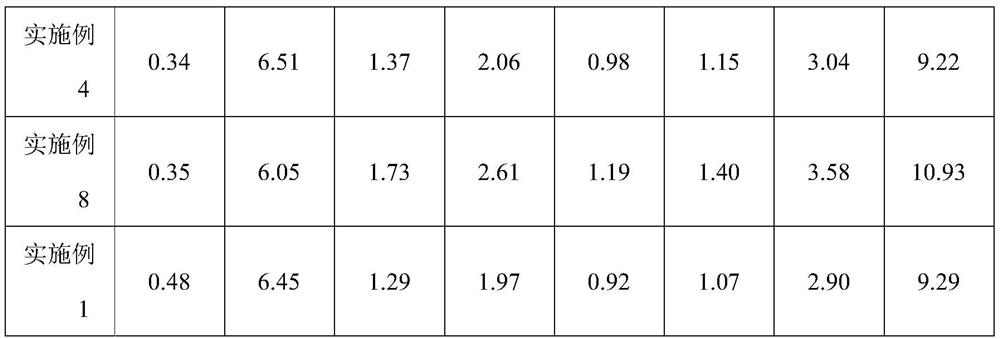

[0046] According to the method stipulated in the national standard "GB / T 18013-2008 Determination of Accelerated Storage Hardening Value of Natural Raw Rubber", during the accelerated storage process of the prepared constant-viscosity natural rubber, the initial value of the Wallace plasticity of the raw rubber is stored The hardening value w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com