Cross-linked starch for drilling fluid and preparation method thereof

A cross-linked starch and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor viscosity-increasing effect, weak temperature resistance, single function, etc., and achieve outstanding effect and temperature resistance The effect of improving and raising viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

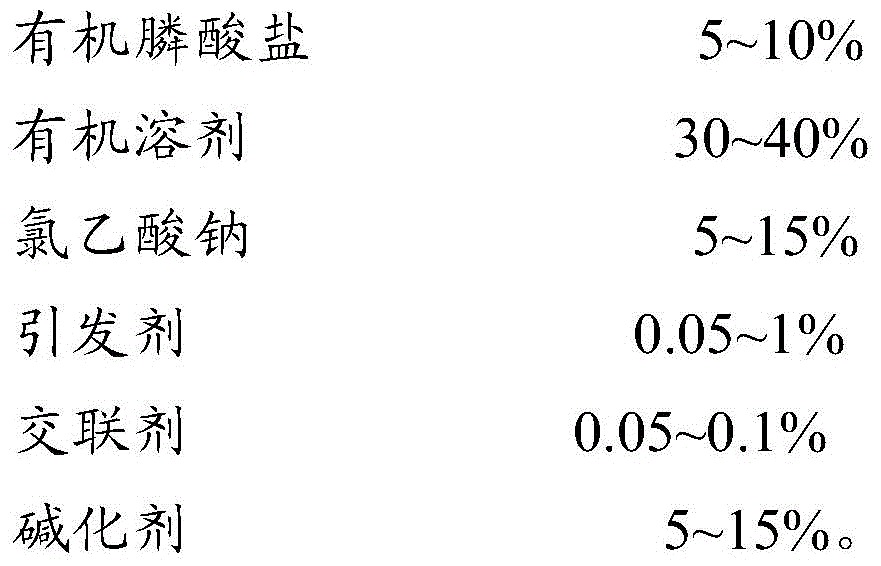

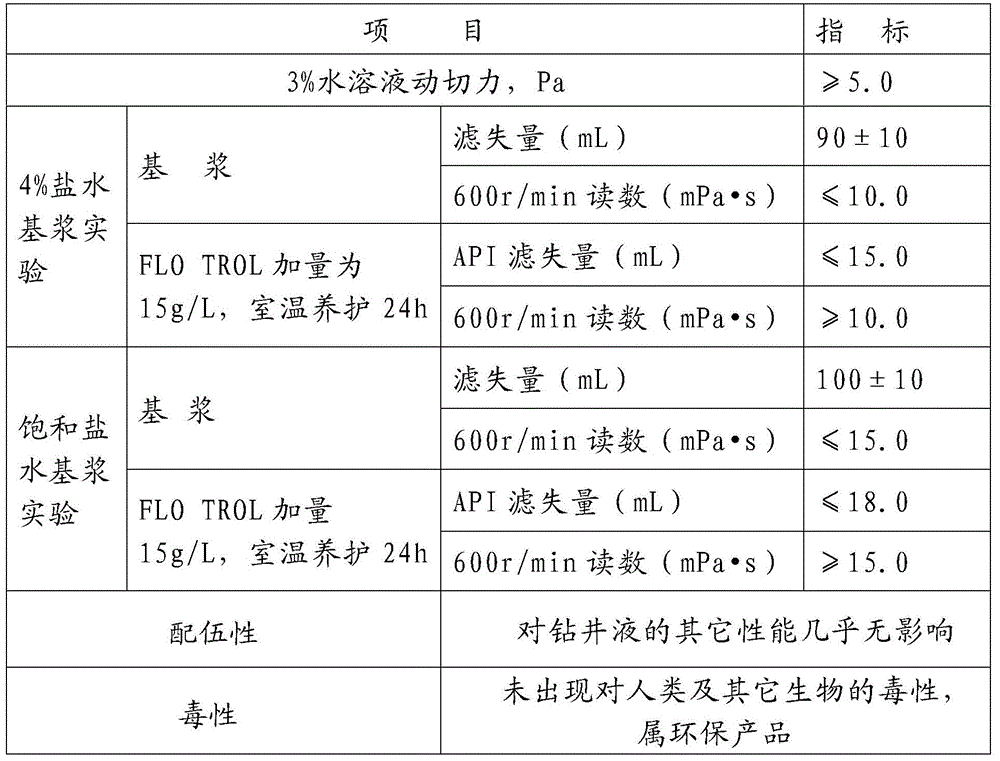

Method used

Image

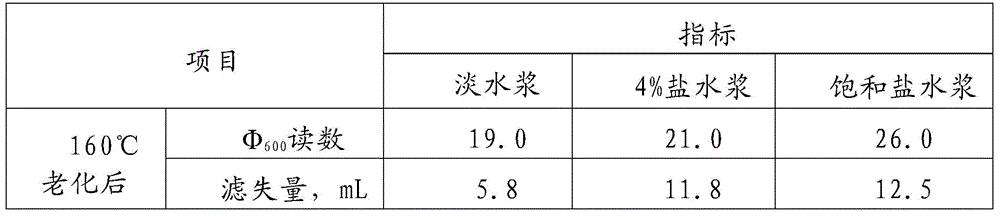

Examples

Embodiment 1

[0028] 100Kg of cornstarch and 30Kg of alcohol (85% v / v) were added to the reactor, and a 30wt% aqueous solution of sodium salicylate phosphonate made by dissolving 6Kg of sodium salicylate phosphate in water was added to the reactor. Mix the solution prepared by dissolving 0.3Kg sodium dihydrogen phosphate in 1.5Kg water and the solution prepared by dissolving 1.8Kg sodium monohydrogen phosphate in 9Kg water to obtain a buffer solution (pH is 7-9), and add the buffer solution to the reaction kettle After stirring evenly, keep the temperature at about 50°C and react for 30 minutes; slowly add 50wt% sodium hydroxide aqueous solution made of 8Kg of sodium hydroxide solution into the reaction kettle, keep the temperature at 70°C, and fully stir for 20 minutes Finally, make 30wt% sodium chloroacetate aqueous solution with 10Kg sodium chloroacetate, and join in the reactor, keep temperature about 70 ℃, fully react 60 minutes; Dissolve 0.07Kg epichlorohydrin in alcohol (85% v / In v)...

Embodiment 2

[0030] Add 100Kg of potato starch and 30Kg of alcohol (90% v / v) into the reactor, dissolve 8Kg of potassium diethylvinylphosphonate in water to make a 30wt% aqueous solution of potassium diethylvinylphosphonate and add it to the reactor , mix the solution prepared by dissolving 0.3Kg sodium dihydrogen phosphate in 1.5Kg water and the solution prepared by dissolving 1.5Kg sodium monohydrogen phosphate in 8Kg water to obtain a buffer solution (pH 7-9), and add the buffer solution to Put it into the reaction kettle, stir evenly, keep the temperature at about 50°C, and react for 30 minutes; dissolve 10Kg of potassium hydroxide in water to make a 50wt% potassium hydroxide aqueous solution, and slowly add it to the reaction kettle, keeping the temperature at 60°C After fully stirring for 30 minutes, the 30wt% sodium chloroacetate aqueous solution made by dissolving 8Kg sodium chloroacetate in water was also added to the reaction kettle, and the temperature was kept at about 60°C. Aft...

Embodiment 3

[0032]Add 60Kg of potato starch, 40Kg of tapioca starch and 35Kg of methanol into the reactor, add 30wt% aqueous pyrophosphate diester solution prepared by dissolving 10Kg of pyrophosphate diester in water, and add 1.6Kg of sodium monohydrogen phosphate into the reactor. The solution prepared in 8Kg water and the solution prepared by dissolving 0.1Kg citric acid in 1.5Kg water are mixed to obtain an alkaline buffer solution (pH is 7-9), and the buffer solution is added to the reaction kettle, and after stirring, keep The temperature is around 60°C, react for 40 minutes; slowly add 50wt% sodium hydroxide aqueous solution made by dissolving 10Kg of sodium hydroxide in water into the reaction kettle, keep the temperature at 70°C, stir well for 20 minutes, then add 8Kg of chloroacetic acid 30wt% sodium chloroacetate aqueous solution made by dissolving sodium in water, keep the temperature at about 70°C, and react for 80 minutes; add 30wt% epichlorohydrin methanol solution made by d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com