A kind of high-strength multi-layer wooden structural material and its manufacturing method

A technology of wood structure and production method, which is applied in wood treatment, wood layered products, wood processing equipment, etc., can solve the problems of low market share, manufacturing standards and insufficient technology, etc., and achieve simple process, high strength and good performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Treatment of oriented strand board (OSB): Sanding both sides of OSB, the sanding thickness is 0.2mm, and the OSB after sanding is placed in the health care room to adjust the moisture content, and the moisture content of OSB is adjusted to 8 %, and then the two faces of the OSB are brushed for later use;

[0037] (2) Treatment of cross-laminated lumber (CLT): carry out health-preserving treatment on the prepared CLT, adjust the water content of CLT to 8%, and then, carry out roughening treatment and stress relief groove processing on the surface, so as to facilitate gluing and Improve dimensional stability;

[0038] (3) Apply glue on the treated OSB surface, and control the amount of double-sided glue at 300g / m 2 , the applied adhesive is polyvinyl acetate isocyanate adhesive (EPI);

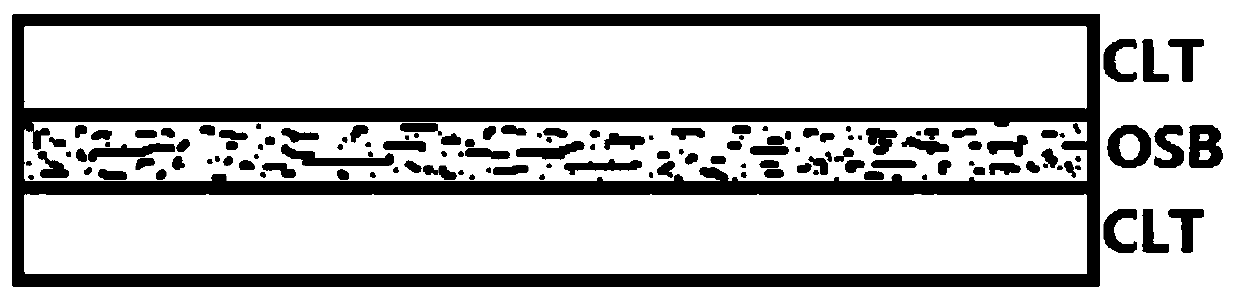

[0039] (4) The glued OSB and CLT are stacked and paved to form a CLT-OSB-CLT three-layer wooden structural material with a size of 2440*1220*100mm;

[0040] (5) Send the wooden stru...

Embodiment 2

[0043] (1) Treatment of oriented strand board (OSB): sanding both sides of the OSB, the sanding thickness is 0.2mm, and the OSB after sanding is placed in the health care room to adjust the moisture content, and the moisture content of the OSB is adjusted to 6 %, and then the two faces of the OSB are brushed for later use;

[0044] (2) Treatment of cross-laminated lumber (CLT): carry out health-preserving treatment on the prepared CLT, adjust the moisture content of CLT to 6%, and then, carry out roughening treatment and processing of stress relief grooves on the surface to facilitate gluing and Improve dimensional stability;

[0045] (3) Apply glue on the surface of OSB that has been treated, and control the amount of double-sided glue at 280g / m 2 , the applied adhesive is melamine-urea-formaldehyde resin adhesive (MUF), ammonium persulfate is selected as the curing agent, and the addition amount is 5% of the solid content of MUF;

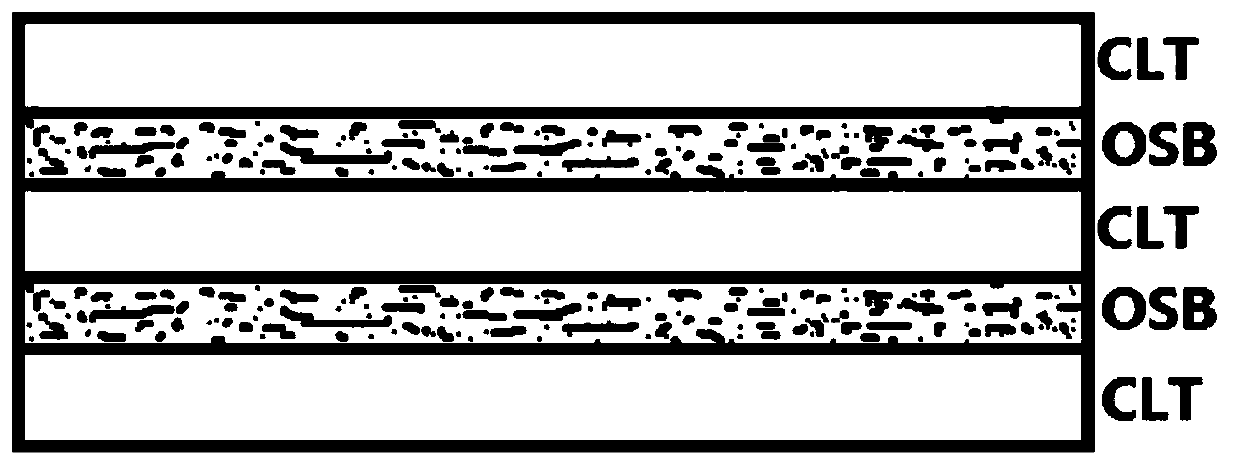

[0046] (4) The glued OSB and CLT are stacke...

Embodiment 3

[0050] (1) Treatment of oriented strand board (OSB): Sanding both sides of OSB, the sanding thickness is 0.2mm, and the OSB after sanding is placed in the health care room to adjust the moisture content, and the moisture content of OSB is adjusted to 8 %, and then the two faces of the OSB are brushed for later use;

[0051] (2) Treatment of cross-laminated lumber (CLT): carry out health-preserving treatment on the prepared CLT, adjust the water content of CLT to 8%, and then, carry out roughening treatment and stress relief groove processing on the surface, so as to facilitate gluing and Improve dimensional stability;

[0052] (3) Apply glue on the treated OSB surface, and control the amount of double-sided glue at 300g / m 2 , the applied adhesive is tannin-resorcinol-glutaraldehyde adhesive (TRG), paraformaldehyde is selected as the curing agent, and the addition amount is 9% of the solid content of TRG.

[0053] (4) The glued OSB and CLT are stacked and paved to form a CLT-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com