Biomass carbon/molybdenum disulfide nano composite material and preparation method thereof

A nano-composite material, biomass carbon technology, applied in molybdenum sulfide, chemical instruments and methods, physical/chemical process catalysts, etc. Broad prospects, good electrical conductivity, and the effect of increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

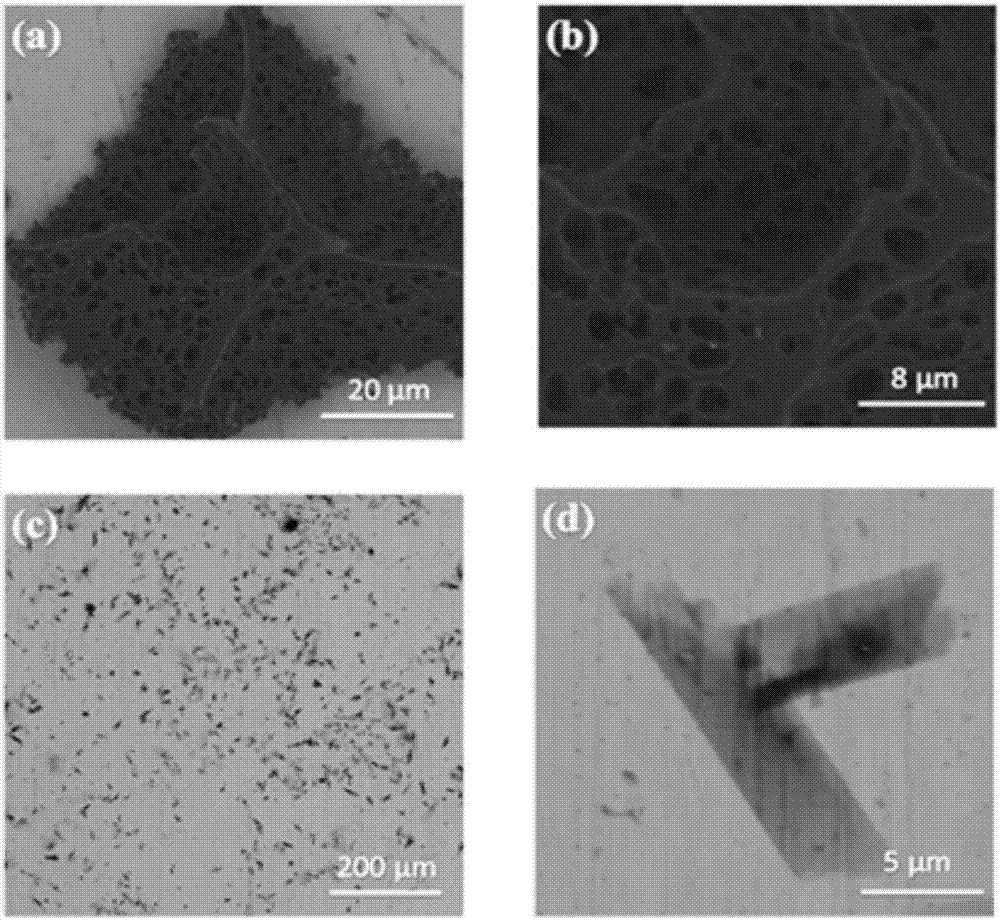

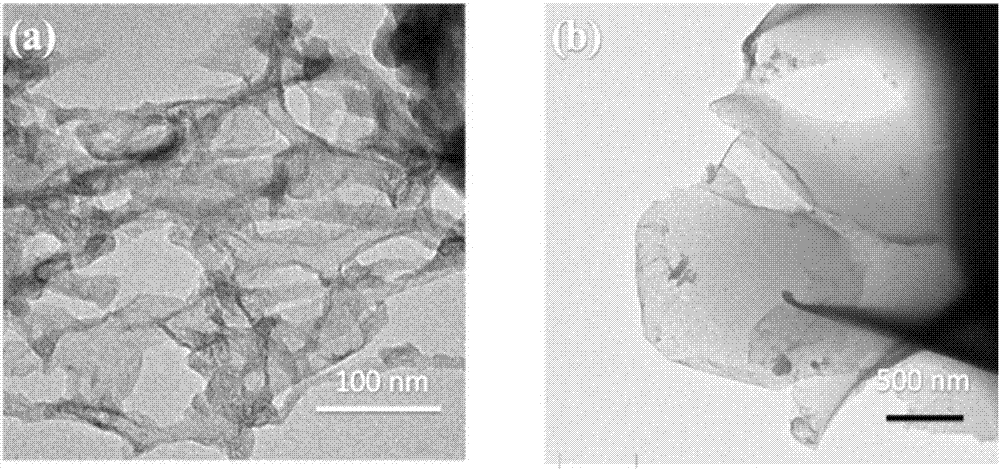

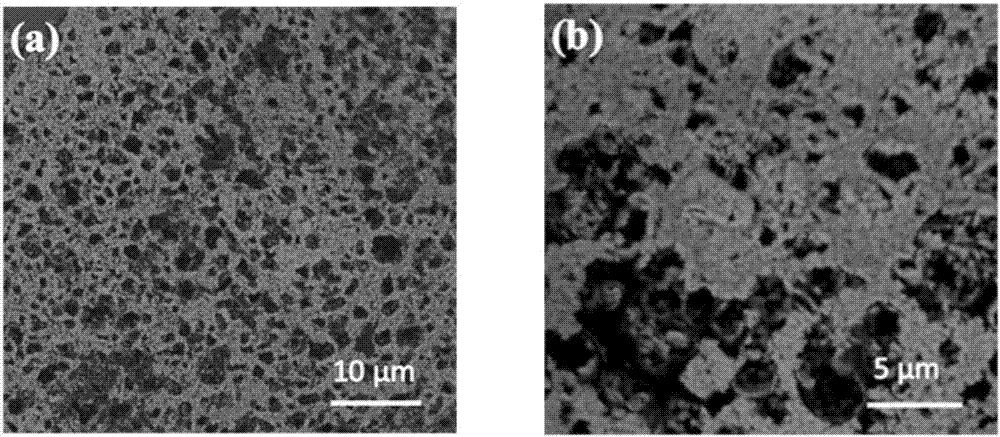

Image

Examples

Embodiment 1

[0031] (1) Preparation of biomass carbon by hydrothermal method:

[0032] Accurately weigh 1.5 g of pretreated corn stalks (soaked in absolute ethanol for one week and then dry thoroughly) to the lining of a hydrothermal kettle, add 2.5 ml of concentrated sulfuric acid and 50 ml of ultrapure water, mix well, seal, and store at 180°C Under hydrothermal reaction for 48 h, natural cooling.

[0033] Biomass carbon was collected by filtration, washed three times with ultrapure water, and then thoroughly washed and dried with ethanol.

[0034] The dry biomass carbon was mixed with the active substance potassium hydroxide (KOH) at a mass ratio of 1:2, and ground evenly in an agate mortar.

[0035] Biomass carbon mixed with active material was placed in a tube furnace, pre-gassed with nitrogen (N 2 ) 30min to remove the air and start calcining. Using staged heating, first raise the temperature to 400°C and keep it for 30min, then raise the temperature to 800°C and keep it for 1h, t...

Embodiment 2

[0043] (1) Preparation of biomass carbon by hydrothermal method:

[0044] Accurately weigh 1.5 g of pretreated corn stalks into the lining of a hydrothermal kettle, add 2.5 ml of concentrated sulfuric acid and 50 ml of ultrapure water, mix evenly, seal, hydrothermally react at 200 °C for 36 h, and cool naturally.

[0045] Biomass carbon was collected by filtration, washed three times with ultrapure water, and then thoroughly washed and dried with ethanol.

[0046] The dry biomass carbon was mixed with the active substance potassium hydroxide (KOH) at a mass ratio of 1:3, and ground evenly in an agate mortar.

[0047] Biomass carbon mixed with active material was placed in a tube furnace, pre-gassed with nitrogen (N 2 ) 30min to remove the air and start calcining. Using staged heating, first raise the temperature to 400°C and keep it for 30min, then raise the temperature to 800°C and keep it for 1h, then cool naturally. The heating rate is 10°C / min.

[0048] The activated b...

Embodiment 3

[0053] (1) Preparation of biomass carbon by hydrothermal method:

[0054] Accurately weigh 1.5 g of pretreated corn stalks into the lining of a hydrothermal kettle, add 2.5 ml of concentrated sulfuric acid and 50 ml of ultrapure water, mix well and seal, hydrothermally react at 180 °C for 48 h, and cool naturally.

[0055] Biomass carbon was collected by filtration, washed three times with ultrapure water, and then thoroughly washed and dried with ethanol.

[0056] The dry biomass carbon was mixed with the active substance potassium hydroxide (KOH) at a mass ratio of 1:2, and ground evenly in an agate mortar.

[0057] Biomass carbon mixed with active material was placed in a tube furnace, pre-gassed with nitrogen (N 2 ) 30min to remove the air and start calcining. Using staged heating, first raise the temperature to 400°C and keep it for 30min, then raise the temperature to 800°C and keep it for 1h, then cool naturally. The heating rate is 10°C / min.

[0058] The activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com