A kind of rush magnetic powder for dyeing wastewater treatment and its preparation method and application

A technology for magnetic powder and dyeing wastewater, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Effect of specific surface area, improving adsorption rate and adsorption efficiency, and increasing dye adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method for rush magnetic powder for dyeing wastewater treatment, comprising the following steps:

[0042] S1. Put the rush powder in a hydrothermal reaction kettle, use water as the medium, take it out after hydrothermal reaction at 250-290°C for 1.5-2.5 hours, filter, wash, and dry to obtain the rush hydrothermal charcoal powder;

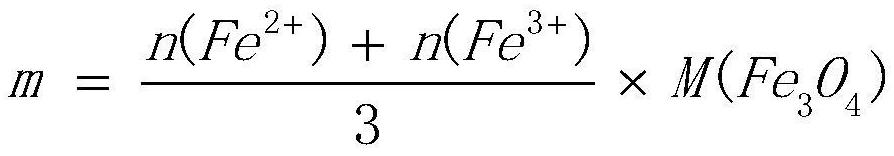

[0043] S2. Take ferric salt and ferrous salt, press Fe 3+ with Fe 2+ The molar ratio of substances is 1.5-2:1, and the iron ion solution is prepared;

[0044] S3. Add the rush hydrothermal charcoal powder obtained in step S1 to the iron ion solution obtained in step S2, then slowly add the alkali solution dropwise, age at a temperature of 55-85°C for 1-8 hours, and then filter , washing and drying to obtain the rush magnetic powder.

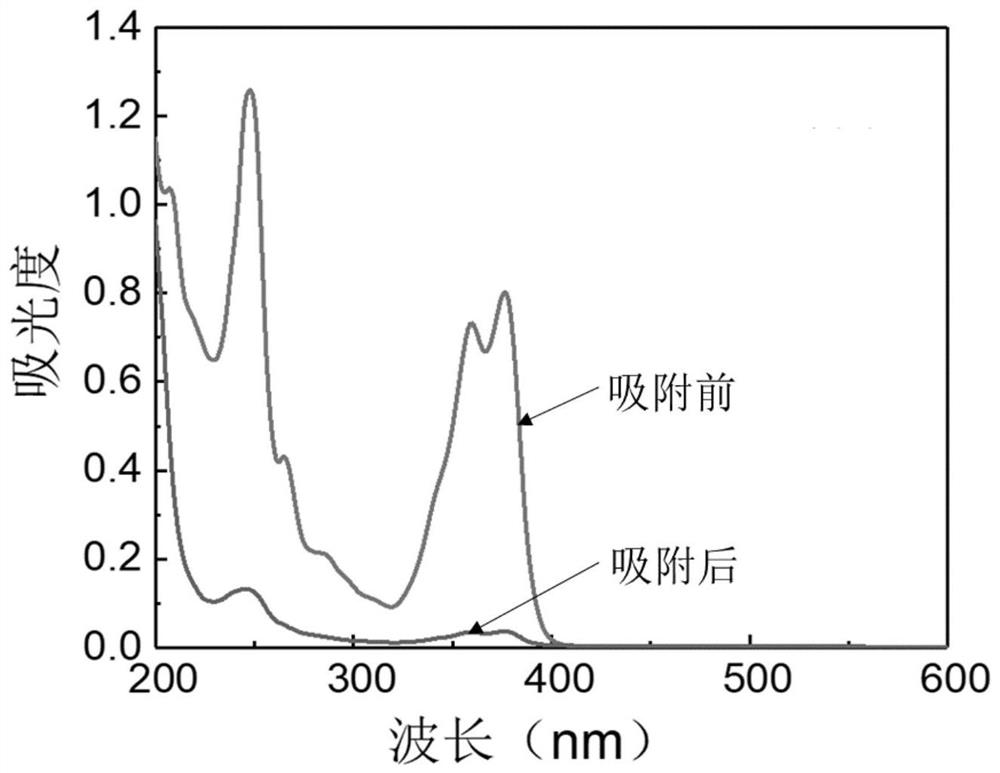

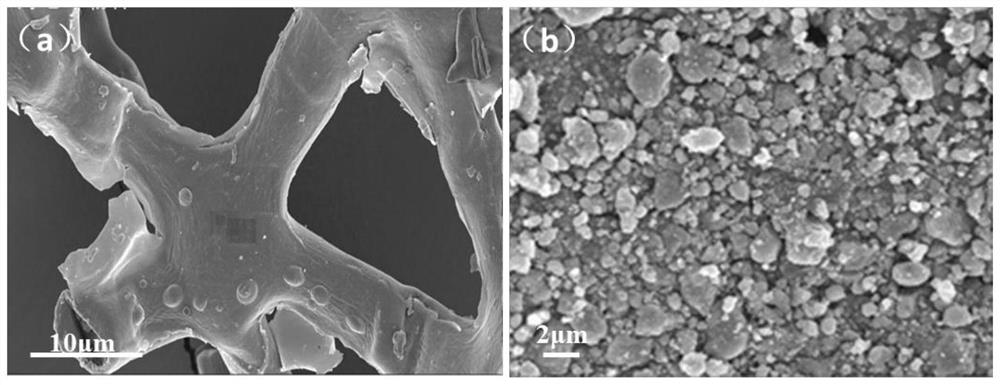

[0045] Through the above preparation method, the rush grass with abundant resources and excellent specific surface area and porosity is selected as the matrix adsorption material. First, the ru...

Embodiment 1

[0063] A rush magnetic powder for dyeing wastewater treatment, prepared by the following steps:

[0064] S1. Take 2g of rush powder and put it in a hydrothermal reaction kettle, add 50ml of deionized water, put it in an oven at 270°C, take it out after hydrothermal reaction for 2 hours, filter, wash until the filtrate is clear water, put it in an oven at 100°C Dry for 2 hours to obtain rush hydrothermal charcoal powder;

[0065] S2. Take 1.95g of ferrous sulfate and place it in a 500ml beaker, add 200ml of deionized water, stir at 400r / min at 70°C until dissolved, slowly add 3.9g of ferric chloride during stirring, and stir for 30min to obtain Iron ion solution;

[0066] S3. Add 1.624g rushes hydrothermal charcoal powder to iron ion solution, stir 30min, obtain reaction liquid; Then get 10g sodium hydroxide and dissolve in 50ml water, obtain concentration and be the sodium hydroxide aqueous solution of 20mg / ml, sodium hydroxide Slowly drip the aqueous solution into the react...

Embodiment 2 and 3 and comparative example 1 and 2

[0079] Compared with Example 1, the rush magnetic powders provided in Examples 2 and 3 and Comparative Examples 1 and 2 for dyeing wastewater treatment are different in that the temperature of the hydrothermal reaction in step S1 is as shown in Table 1 , the others are basically the same as in Embodiment 1, and will not be repeated here.

[0080] The preparation conditions and adsorption properties of table 1 embodiment 2 and 3 and comparative examples 1 and 2

[0081] sample Hydrothermal reaction temperature (℃) Adsorption rate(%) Example 2 265 80% Example 3 290 95% Comparative example 1 240 75% Comparative example 2 300 94%

[0082] It can be seen from Table 1 that when the hydrothermal reaction temperature is lowered, the rushes can not fully react, so the adsorption rate is significantly reduced;

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com