Absorption-stabilization process method

A process method and absorption stabilization technology, which are used in the petroleum industry, gas mixture processing, and hydrocarbon oil treatment, etc., can solve the problems of reducing the amount of stabilized gasoline supplements and have little effect, achieving reliable product quality and reducing the load of the absorption tower. , Advanced effect of device energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

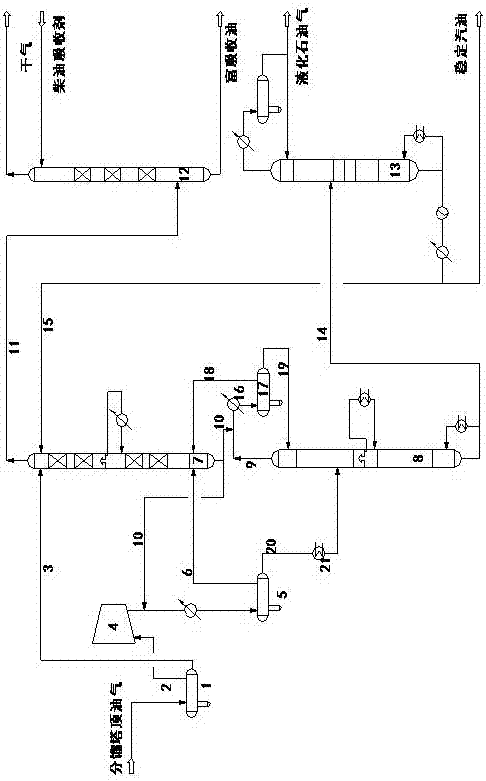

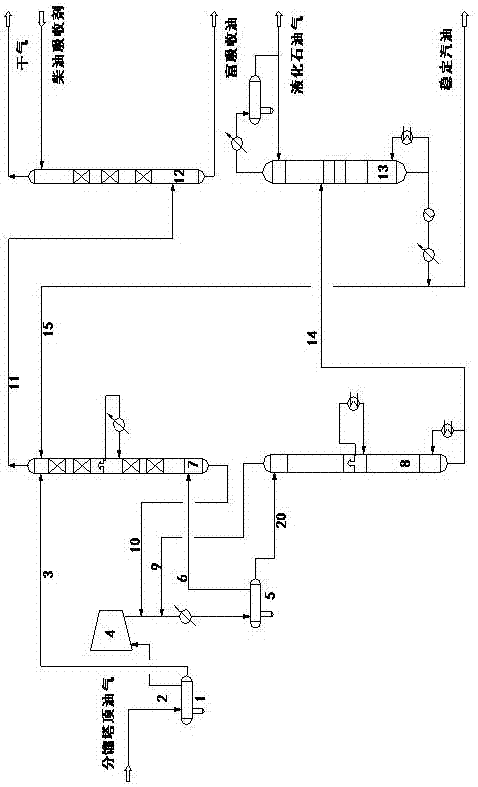

Image

Examples

Embodiment 1

[0033] Taking the absorption stabilization unit of the 3 million tons / year coking unit as an example, the process simulation software ProⅡ is used for simulation analysis.

[0034] The simulation flow is consistent with the process flow of the present invention. From the oil gas at the top of the coking fractionation tower, the rich gas 2 and naphtha 3 are separated in the gas-liquid separation tank 1 at the top of the tower. The rich gas 2 is boosted by the rich gas compressor 4 and mixed with a part of the absorption tower bottom oil 10 from the absorption tower 7 to cool down and enter the rich gas balance tank 5 . The gas phase 6 balanced by the rich gas balance tank 5 enters the bottom of the absorption tower 7; the liquid phase enters the upper part of the desorption tower 8 after being heated by the liquid phase heater 21 of the rich gas balance tank. The desorption gas 9 desorbed by the desorption tower 8 is mixed with part of the absorption tower bottom oil 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com