Complexing agent used for chemical copper plating solution and preparation method of complexing agent

A technology of electroless copper plating and complexing agent, which is applied in the field of complexing agent for electroless copper plating solution and its preparation, which can solve the problems of affecting the bonding strength of the plating layer and the substrate, affecting the thickness of the activated copper layer of the bath, and achieving brittleness. Small, avoiding the effect of bonding strength and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Raw materials: potassium sodium tartrate 150kg, sodium hydroxide 180kg, additive nickel sulfate 20L, water 1000L.

[0011] The preparation method, the specific steps are as follows: 1) Add potassium sodium tartrate to water, stir and dissolve until clear, and control the temperature at 20-30°C; 2) Add sodium hydroxide, stir and dissolve until clear, and control the temperature below 70°C; 3) Add additive M, and control the temperature at 40-50°C.

Embodiment 2

[0013] Raw materials: potassium sodium tartrate 150 kg, sodium hydroxide 200 kg, additive nickel sulfate 30 L, water 1000 L.

[0014] The preparation method, the specific steps are as follows: 1) Add potassium sodium tartrate to water, stir and dissolve until clear, and control the temperature at 20-30°C; 2) Add sodium hydroxide, stir and dissolve until clear, and control the temperature below 70°C; 3) Add additive M, and control the temperature at 40-50°C.

Embodiment 3

[0016] Raw materials: potassium sodium tartrate 160 kg, sodium hydroxide 180 kg, additive nickel sulfate 20L, water 1000L.

[0017] The preparation method, the specific steps are as follows: 1) Add potassium sodium tartrate to water, stir and dissolve until clear, and control the temperature at 20-30°C; 2) Add sodium hydroxide, stir and dissolve until clear, and control the temperature below 70°C; 3) Add additive M, and control the temperature at 40-50°C.

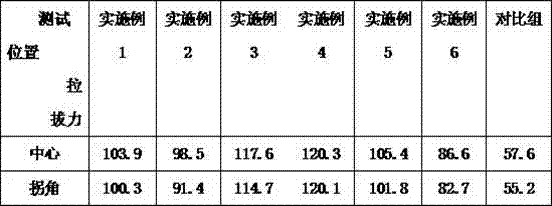

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulling force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com