A preparation method of highly oxidative porphyrin-sensitized sno2 biomimetic photoanode

A photoanode and high oxidation technology, applied in photosensitive equipment, photovoltaic power generation, capacitors, etc., can solve the problems of poor optical performance and chemical property stability, high cost of water oxidation photoanode, and low water splitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0051] Specific implementation mode 1: This implementation mode is a highly oxidative porphyrin sensitized SnO 2 The biomimetic photoanode preparation method is specifically completed according to the following steps:

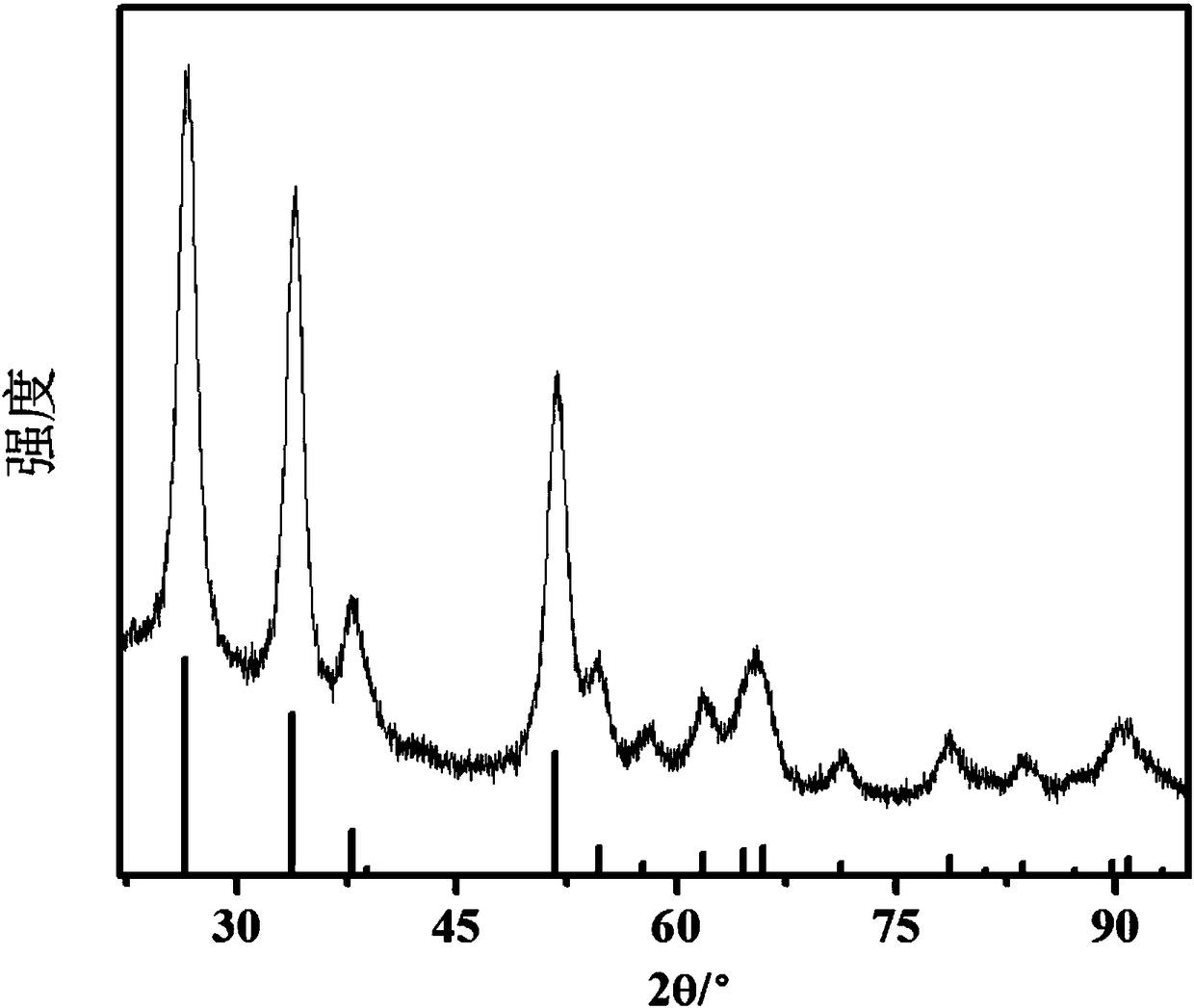

[0052] 1. Preparation of SnO 2 Powder:

[0053] Add stannous chloride dihydrate into deionized water, and then stir evenly to obtain a milky white suspension; add dropwise concentrated nitric acid with a mass fraction of 65% to the milky white suspension under the condition of stirring again to obtain a light yellow solution; using mass fraction of 25% to 28% ammonia water to adjust the pH value of the light yellow solution to 7 to obtain a white gel; use deionized water to wash the white gel centrifugally until the white gel does not contain chlorine ions to obtain a white gel that removes chloride ions; put the white gel that removes chloride ions into a hydrothermal reaction kettle, then conduct a hydrothermal reaction at a temperature of 180°C to 200°C fo...

specific Embodiment approach 2

[0087] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, tin protochloride dihydrate is added to deionized water, and then stir evenly to obtain a milky white suspension; Adding concentrated nitric acid with a mass fraction of 65% to the milky white suspension to obtain a light yellow solution; using ammonia water with a mass fraction of 25% to adjust the pH value of the light yellow solution to 7 to obtain a white gel; Centrifugal washing of the white gel with ionized water until the white gel does not contain chloride ions, and the white gel with chloride ions removed is obtained; the white gel with chloride ions removed is put into a hydrothermal reaction kettle, and then heated at a temperature of 190°C Underwater thermal reaction for 24 hours, then naturally cooled to room temperature to obtain a white solid; use deionized water to centrifuge wash the white solid 4 times, then dry, grind the dried white solid to ob...

specific Embodiment approach 3

[0088] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the SnO described in step 2 2 The mass ratio of powder to terpineol is 1:4.6; the SnO 2 The mass ratio of powder to ethyl cellulose is 1:0.27; the SnO 2 The mass ratio of powder to absolute ethanol is 1:0.9. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com