Control system and control method capable of automatically judging and setting laser frequency and power

An automatic judgment and control system technology, applied in the field of optoelectronics, can solve problems such as equipment not working properly, affecting the output frequency of the laser, adjusting the laser frequency to the target value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

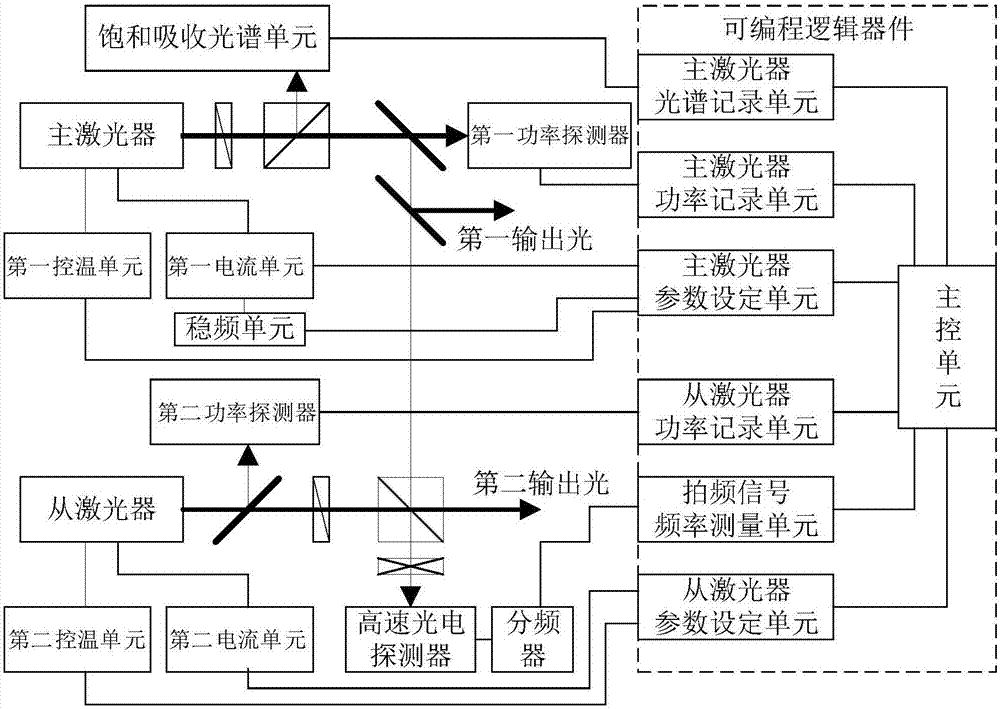

[0046] like figure 1As shown, the control system for automatically judging and setting the laser frequency and power in this embodiment includes: a master laser, a slave laser, a first temperature control unit, a second temperature control unit, a first current unit, a second current unit, and a second current unit. A power detector, a second power detector, a saturated absorption spectrum unit, a frequency stabilization unit, a high-speed photodetector, a frequency divider, a first high-reflection beam splitter, a second high-reflection beam splitter, a high-transmission beam splitter, a first A half-wave plate, a second half-wave plate, a quarter-wave plate, a first polarizing beam splitting prism, a second polarizing beam splitting prism, and a programmable logic device CPLD; wherein, the programmable logic device CPLD The master laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com