Double-side staggered-tooth low thrust fluctuation permanent magnetic synchronous linear motor

A permanent magnet synchronous linear, low thrust technology, applied in electrical components, electromechanical devices, propulsion systems, etc., can solve problems such as thrust fluctuations of dual-primary permanent magnet synchronous linear motors, and achieve the effect of improving performance and suppressing thrust fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

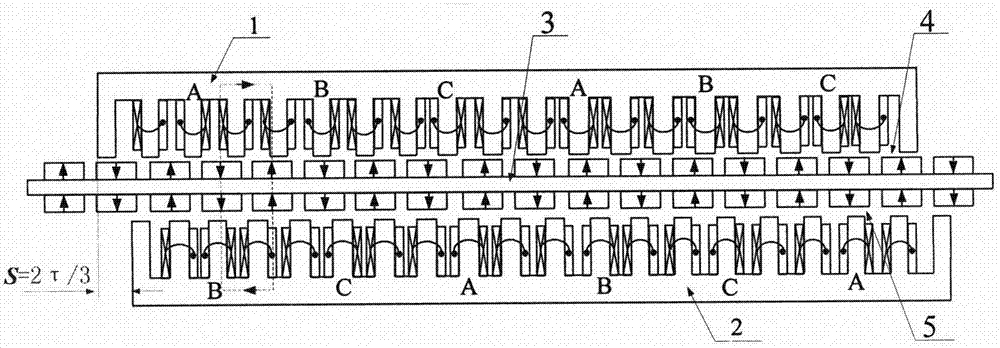

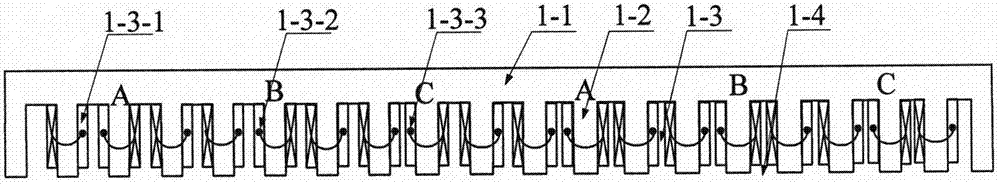

[0022] Such as figure 1 , 2 As shown in, 3, 4, and 5, this embodiment is a double-sided staggered 2τ / 3 low-thrust-pulsation permanent magnet synchronous linear motor, and its pole-slot coordination is a 16-pole 18-slot structure. Double-sided staggered teeth 2τ / 3 low thrust fluctuation permanent magnet synchronous linear motor, which includes a primary component 1, a primary component 2 and a secondary component 3. The primary component 1 consists of a core yoke 1-1, core teeth 1-2 and armature winding 1-3. Primary component two 2 is composed of core yoke 2-1, core teeth 2-2 and armature winding 2-3. The secondary assembly 3 is composed of a permanent magnet 3-1 and a yoke plate 3-2. Each pair of poles includes four permanent magnets. The permanent magnets 3-1-1 and 3-1-3 are located on both sides of the yoke plate 3-2. The magnetizing direction of the permanent magnet 3-1-2 is the same as that of the permanent magnet 3-1-4. The adjacent permanent magnets 3-1-1 and 3-1-2 loca...

Embodiment approach 2

[0028] The difference between this embodiment and the first embodiment is: Image 6 with Figure 7 As shown, the displacement of the primary component 1 and the primary component 2 in the lateral direction is S=τ / 3 (τ is the pole pitch of the motor), that is, the electric angle is 60°.

[0029] On the primary component 1, the phase A winding 1-3-1 is arranged in the first to fourth slots 1-4, the winding adopts a concentrated winding structure, and the first slot is half-filled; the B-phase winding 1-3-1 2 is arranged in the 4th slot; the C-phase winding 1-3-2 is arranged in the 7th to the 10th slot; the windings in the 1st to the 10th slot form a unit motor winding structure; the second The windings of the unit motor are arranged in the 10th-19th slots, and the structure is exactly the same as that of the first unit motor.

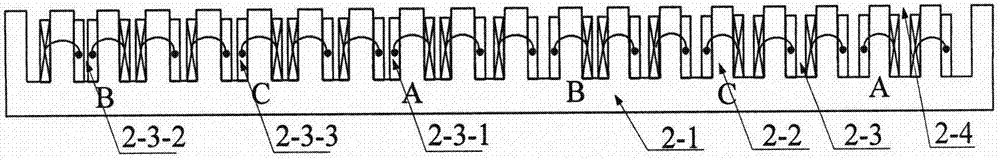

[0030] On the primary component two 2, the C-phase winding 2-3-3 is arranged in the first 1-4 slots 2-4, the winding adopts a concentrated winding structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com