Improved chlorine dioxide generator

A chlorine dioxide generator technology, applied in the direction of chlorine dioxide, chlorine oxide, etc., can solve the problems of low control precision, low production efficiency, and unstable operation, so as to improve reaction efficiency, facilitate maintenance and cleaning, and ensure reaction safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

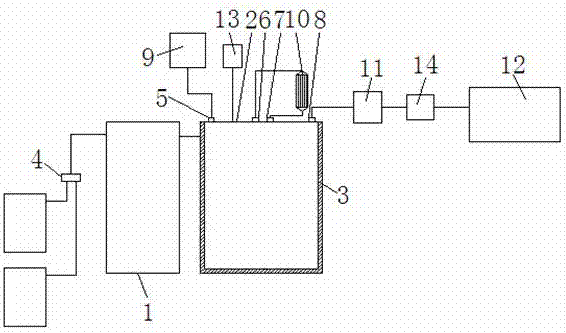

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] like figure 1 As shown, the improved chlorine dioxide generator of the present invention includes a reaction device and a mixing buffer tank 1. The reaction device is composed of a shell 2 and a steam heating layer 3 arranged inside the shell 2. In the A material tank is arranged beside the mixing buffer tank 1, an automatic material proportioner 4 is arranged between the material tank and the mixing buffer tank 1, and an inert gas inlet 5 and a condensation port 6 are respectively arranged on the top of the housing 1 , a reuse port 7 and a gas outlet 8, the inert gas inlet 5 is connected to the inert gas tank 9, a condenser 10 is provided between the condensation port 6 and the reuse port 7, the gas outlet 8 is connected to the water jet The water injector 11 is connected with the storage tank 12; the material tank is divided into a hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com