Immersion lithography system and immersion flow field maintaining method

A technology of immersion lithography and flow field, which is applied in the semiconductor field, can solve the problems of reduced efficiency of immersion lithography, and achieve the effect of improving lithography efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

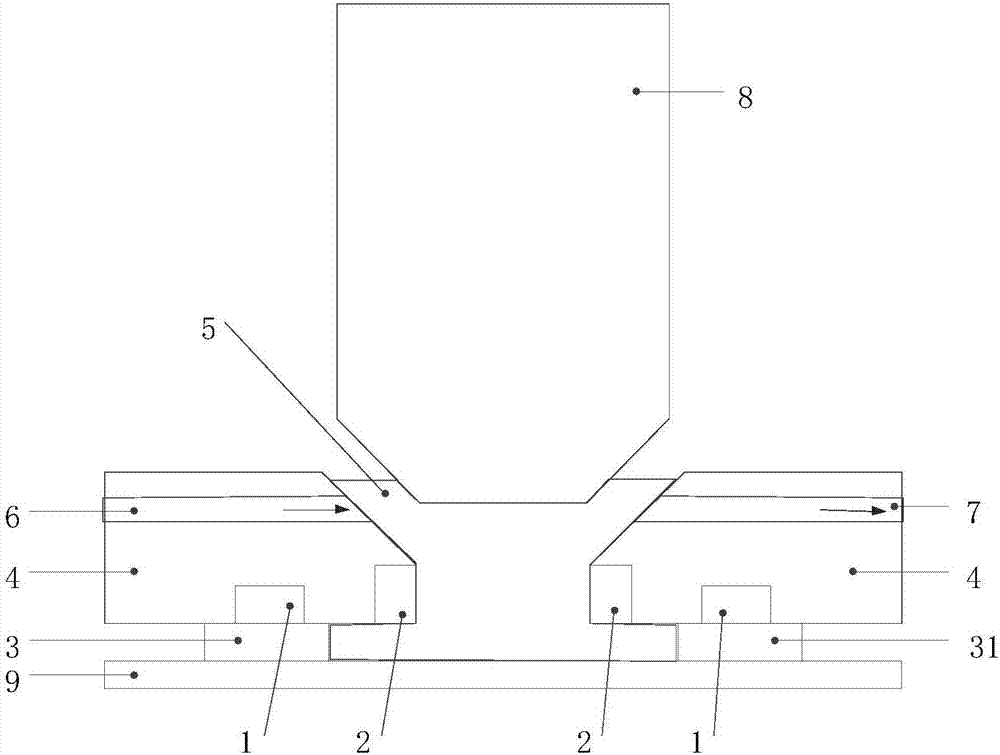

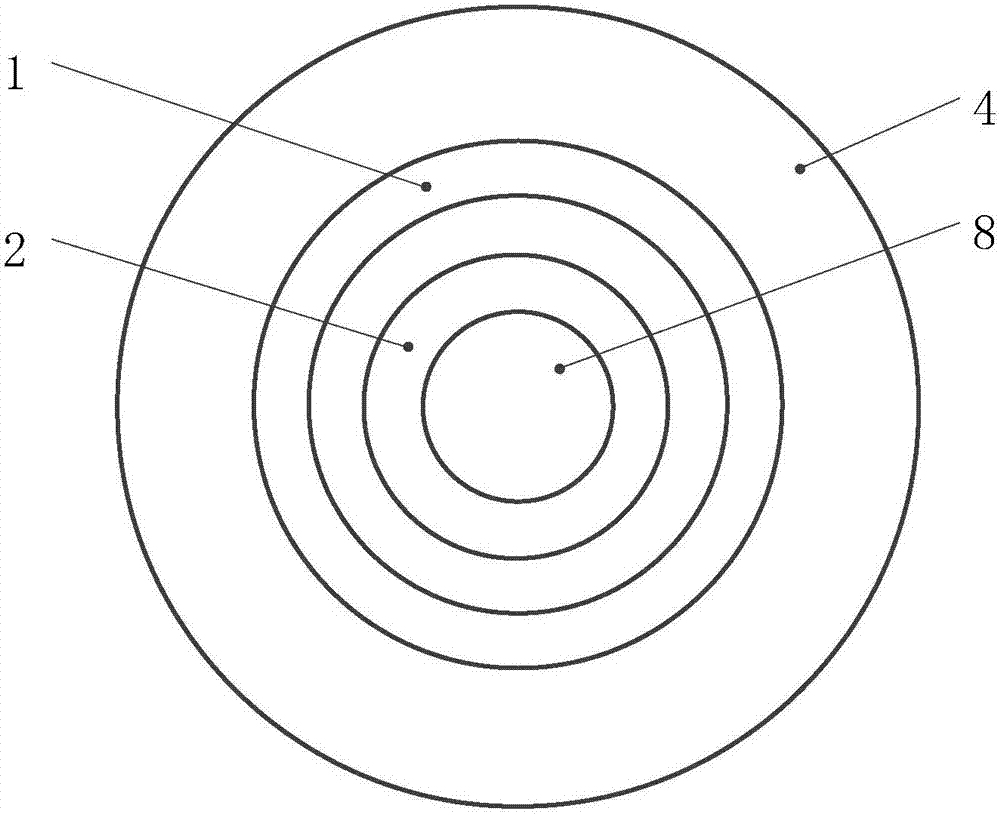

[0044] Please refer to figure 1 , the present invention provides an immersion lithography system, which is the same as the equipment in the traditional lithography system, except that an immersion device, that is, an immersion head 4, is placed between the projection objective lens 8 and the silicon wafer 9. In this embodiment, the immersion The section of the head 4 is circular, and the immersion liquid is placed in the immersion head 4 so that the bottom of the projection objective lens 8 and the upper surface of the silicon wafer 9 are in contact with the immersion liquid.

[0045] In this embodiment, the immersion liquid is a magnetic fluid, which is a stable colloidal solution, which is formed by uniformly dispersing nano-scale magnetic particles in a certain carrier liquid through a surfactant. It has solid magnetic properties and fluidity of the liquid. Since the magnetic fluid has a liquid behavior associated with superparamagnetism and saturation magnetization, it is...

Embodiment 2

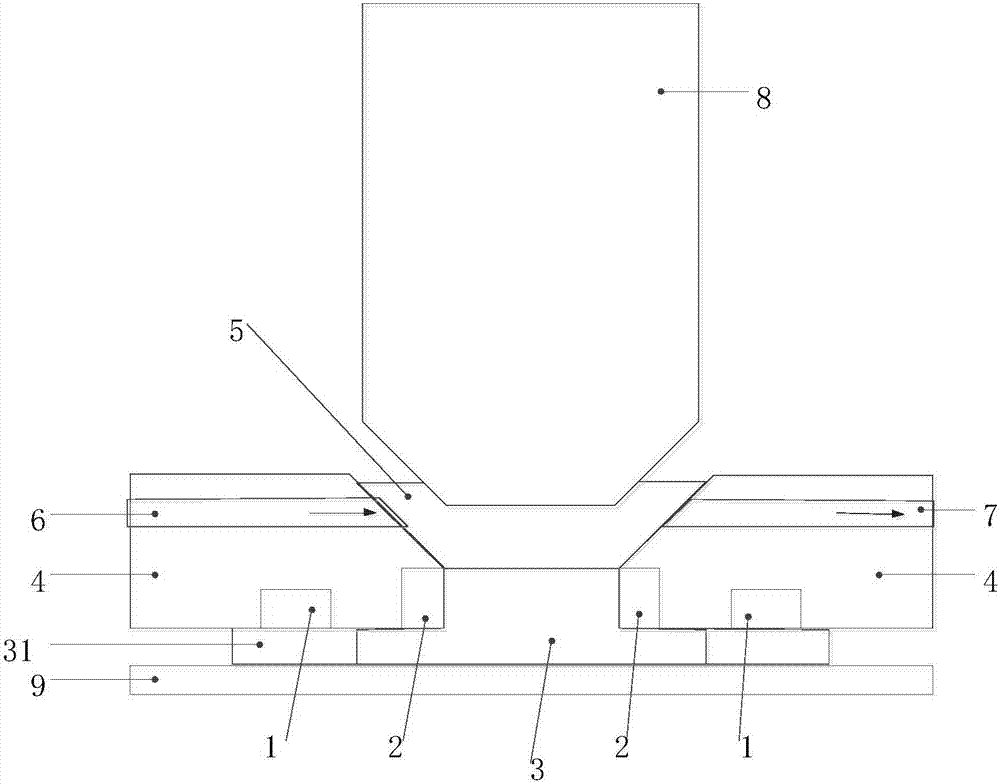

[0055] The difference between this embodiment and Embodiment 1 is that in step S3, the current of the first electromagnetic coil 1 and the second electromagnetic coil 2 is increased, so that all the liquid magnetic fluid 5 solidifies into a solid magnetic fluid 3, which enhances the photolithography system. Stability, to prevent unnecessary flow of the liquid magnetic fluid 5 due to ground vibration and other reasons.

[0056] In summary, the present invention provides an immersion liquid curing device and an immersion flow field maintenance method in the immersion device. During the exposure process, the immersion liquid curing device solidifies the immersion liquid between the immersion device and the silicon wafer 9 to form an annular wall 31 , the immersion device, the annular wall 31 and the silicon wafer 9 form a holding container and hold the immersion liquid, that is, the liquid magnetic fluid 5, and the immersion liquid in the annular wall 31 forms a liquid medium, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com