Combined rotational tillage method capable of harvesting high-yield wheat and corn twice and improving organic carbon content

An organic carbon and combined wheel technology, which is applied in the fields of botany equipment and methods, horticulture, plant cultivation, etc., can solve the problems of high tillage frequency, great destructiveness of the plough layer soil, and high cost and expenditure, so as to accelerate the decomposition of straw, improve the The effect of water storage and moisture retention and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A high-yield and high-efficiency combined rotation method for wheat and jade double cropping, comprising the following steps:

[0027] (1) After summer corn is harvested and before winter wheat is planted, crush the corn stalks to a length less than 5cm, return them to the field, and then carry out subsoiling. The subsoiling range is 60cm, and the subsoiling depth is 35cm. Plowing and deep loosening times are 2 times; the first deep loosening range is 60cm, and the second deep loosening is carried out at intervals within 60cm width, followed by shallow rotary tillage with a depth of 6cm, and the number of times of shallow rotary tillage For 2 times, the straw is fully mixed with the soil. After the winter wheat is harvested in the next year and before the summer corn is sown, the wheat straw is covered and returned to the field. The corn is sown with no tillage, and the wheat straw is evenly covered between the rows;

[0028] (2) In the next cropping period, after summe...

Embodiment 2

[0031] (1) After summer corn is harvested and before winter wheat is planted, crush the corn stalks to a length less than 5cm, return them to the field, and then carry out subsoiling. The subsoiling range is 65cm, and the subsoiling depth is 40cm. plowing and deep loosening times are 2 times; the first deep loosening range is 65cm, the second deep loosening is carried out at intervals within 65cm width, and then shallow rotary tillage is carried out, the depth of rotary tillage is 8cm, and the number of times of shallow rotary tillage For 2 times, the straw is fully mixed with the soil. After the winter wheat is harvested in the next year and before the summer corn is sown, the wheat straw is covered and returned to the field. The corn is sown with no tillage, and the wheat straw is evenly covered between the rows;

[0032] (2) In the next cropping period, after summer corn is harvested and before winter wheat is planted, crush the corn stalks to a length of less than 5 cm and ...

experiment example 1

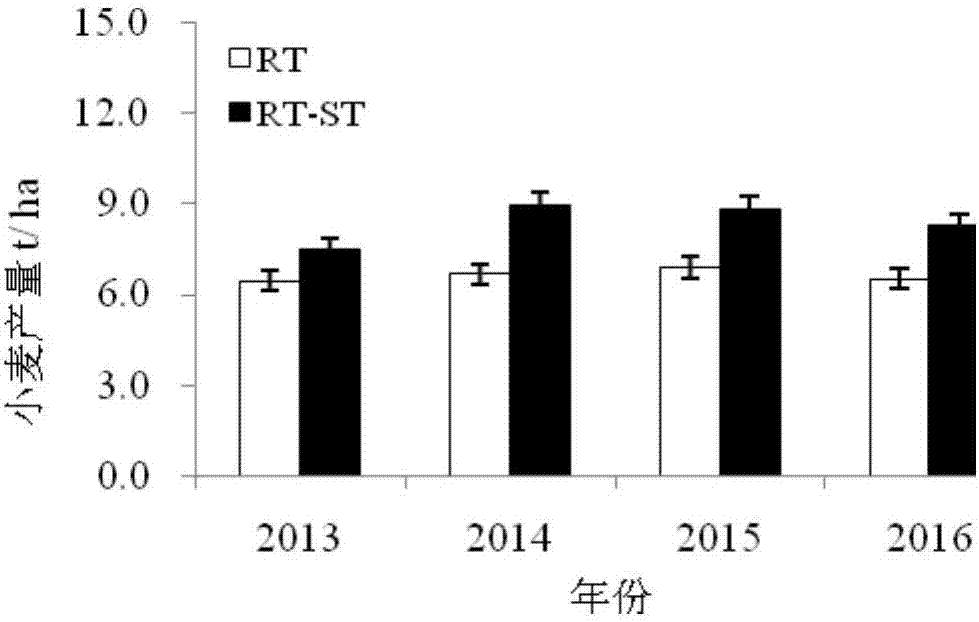

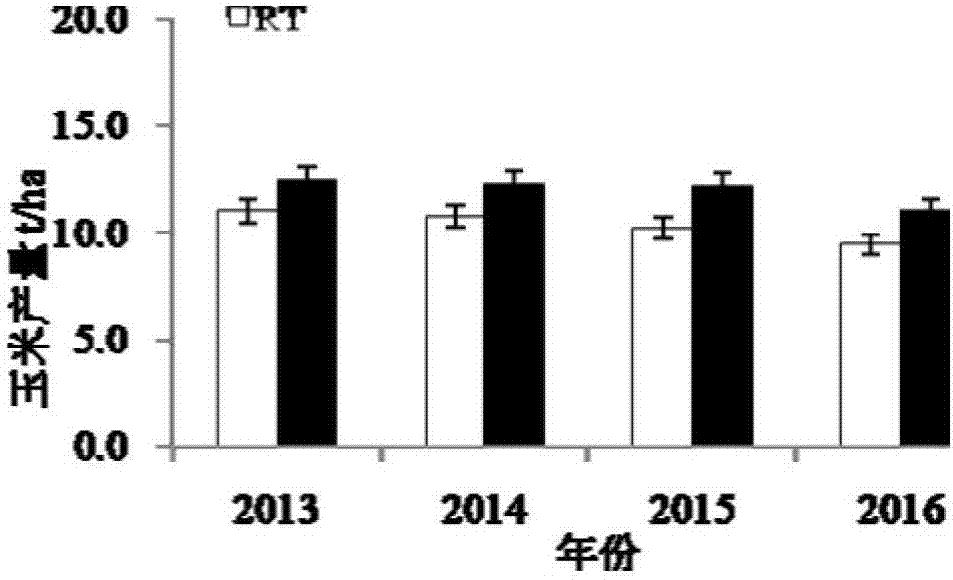

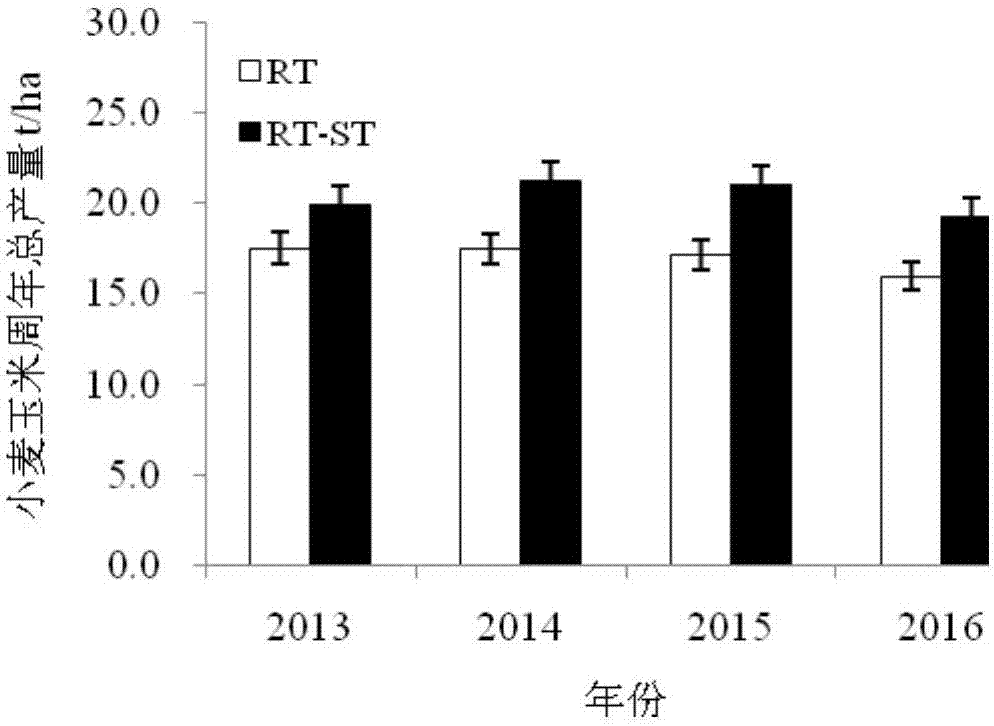

[0037] Experimental example 1: The effect of rotation mode on wheat and corn yields:

[0038]Conservation tillage long-term location test (Tai'an City), the test adopts wheat (Triticum aestivum L.) - corn (Zea mays L.) two-cropping planting pattern a year, and the test group adopts the combination wheel with high yield and organic carbon content of the present invention. Tillage method (set as RT-ST group), and a control group was set up at the same time, the control group was treated with long-term rotary tillage (set as RT group), and all the straw was returned to the field. Wheat is sown from October 10 to 15 each year and harvested from June 8 to 15 the following year; corn is sown from June 18 to 25 and harvested from October 8 to 12 of the year. Unified field management for each treatment, 160kg ha of pure N in the wheat season -1 , P 2 o 5 150kg ha -1 , K 2 O 105kg ha -1 , each treatment was uniformly topdressed with pure N 80kg ha at the jointing stage -1 , wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com