Apparatus and method for making ultrasonically atomized ozone water

A technology for manufacturing devices and ultrasonic waves, which is applied in the field of environmental governance and can solve problems such as by-products, uneconomical, and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

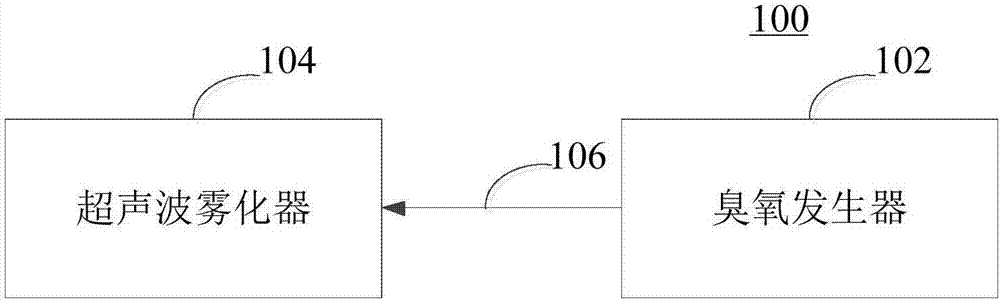

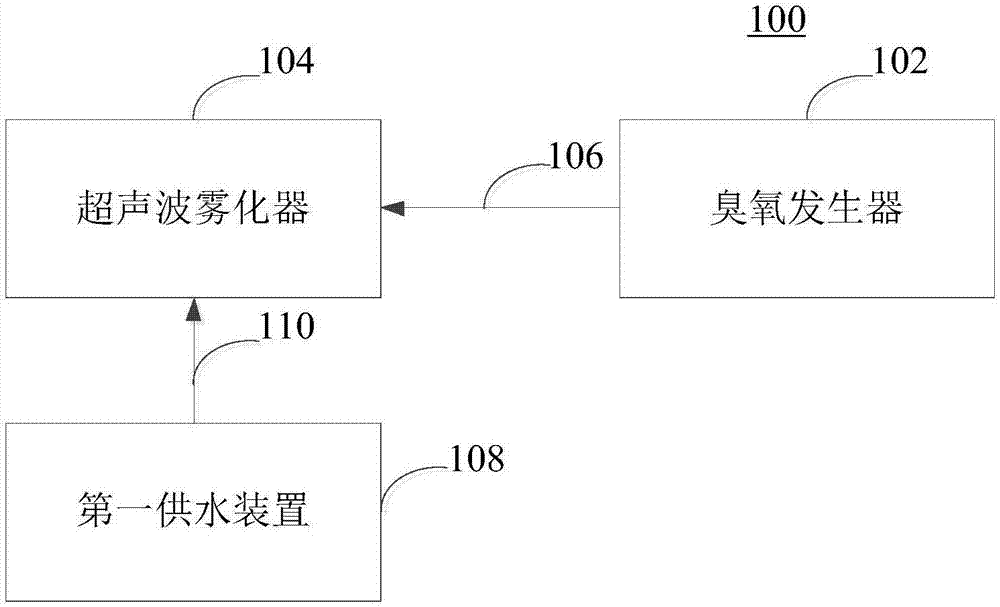

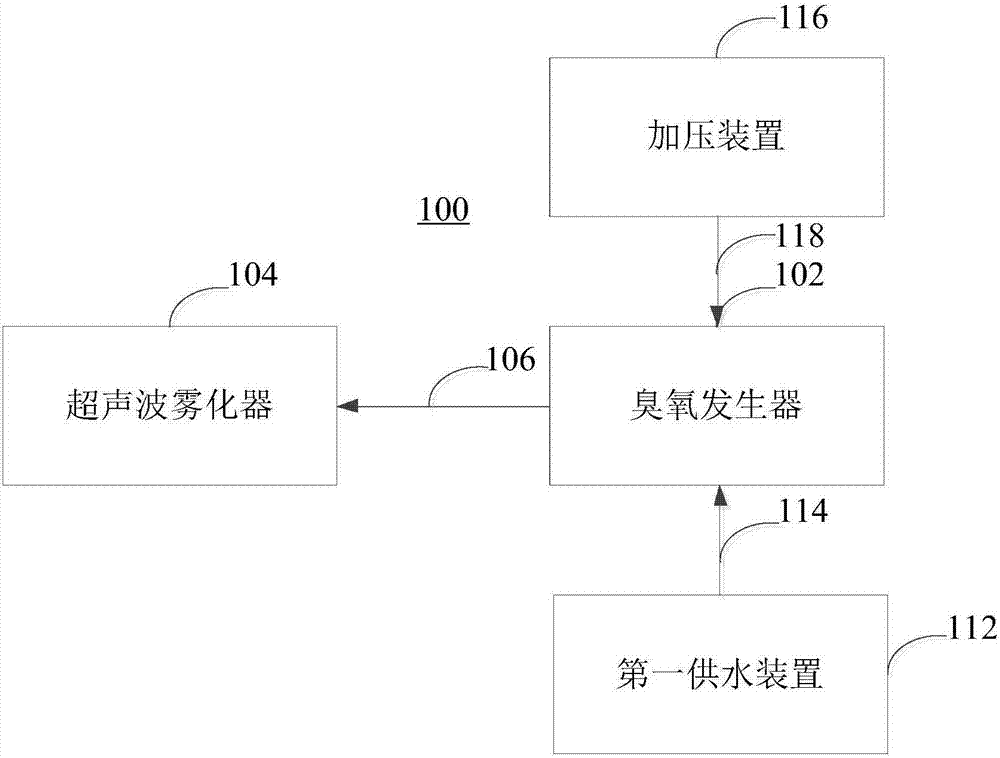

[0035] Please refer to figure 1 , the present embodiment provides a manufacturing device 100 for ultrasonically atomized ozone water, which includes an ozone generator 102, an ultrasonic atomizer 104, and a first pipeline 106, wherein the ozone generator 102 and the ultrasonic atomizer 104 pass through the The first pipe 106 communicates.

[0036] As an implementation of this embodiment, the ozone generator 102 is used to receive air or oxygen, and convert the received air or oxygen into ozone. It can be understood that because the air contains a large amount of impurities, such as nitrogen, helium Therefore, when the ozone generator 102 receives air and converts the air into ozone, it will cause the converted ozone to contain a large amount of impurity elements and make the converted ozone impure; when the ozone generator 102 receives oxygen and converts the oxygen into Ozone does not contain impurity elements. Therefore, preferably, the ozone generator 102 is used to recei...

no. 2 example

[0049] Please refer to Figure 6 , Figure 6 The second embodiment of the present invention provides a schematic flow sheet of a manufacturing method of ultrasonically atomized ozone water, below will aim at Figure 6 The process shown is described. It is applied to the manufacturing device 100 of ultrasonic atomized ozone water, and the manufacturing device 100 of this ultrasonic atomized ozone water comprises an ozone generator 102, an ultrasonic atomizer 104 and a first pipeline 106, and the ozone generator 102 and the ultrasonic atomizer 104 is communicated through a first pipeline 106, and the method includes:

[0050] Step S110: The ozone generator receives the oxygen input from the oxygen generating system.

[0051] Step S120: the ozone generator converts the oxygen into ozone and sends it to the ultrasonic nebulizer through the first pipeline.

[0052] Step S130: The ultrasonic atomizer atomizes water through ultrasonic technology and mixes it with the ozone input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com