Application of a carbon-based catalyst in the catalytic hydrogenation of p-nitrophenol

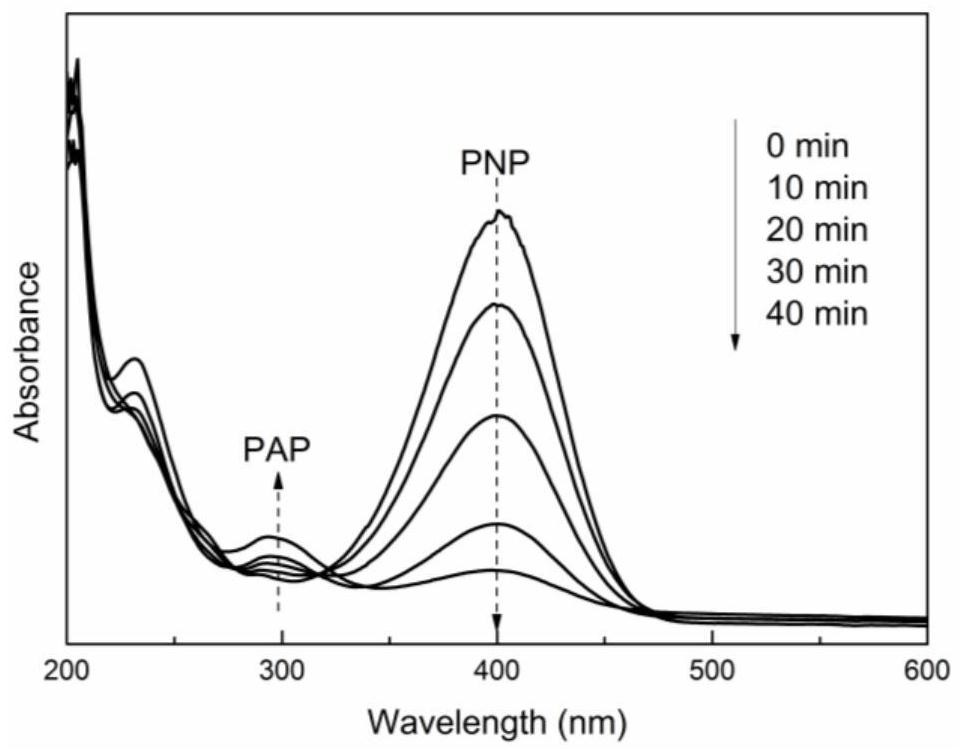

A technology of nitrophenol catalysis and carbon-based catalysts, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve problems involving organic reagents or acid-base conditions, The reaction process is complicated and lengthy, and the recycling performance is poor, so as to achieve the effect of abundant raw materials, cheap and easy-to-obtain raw materials, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

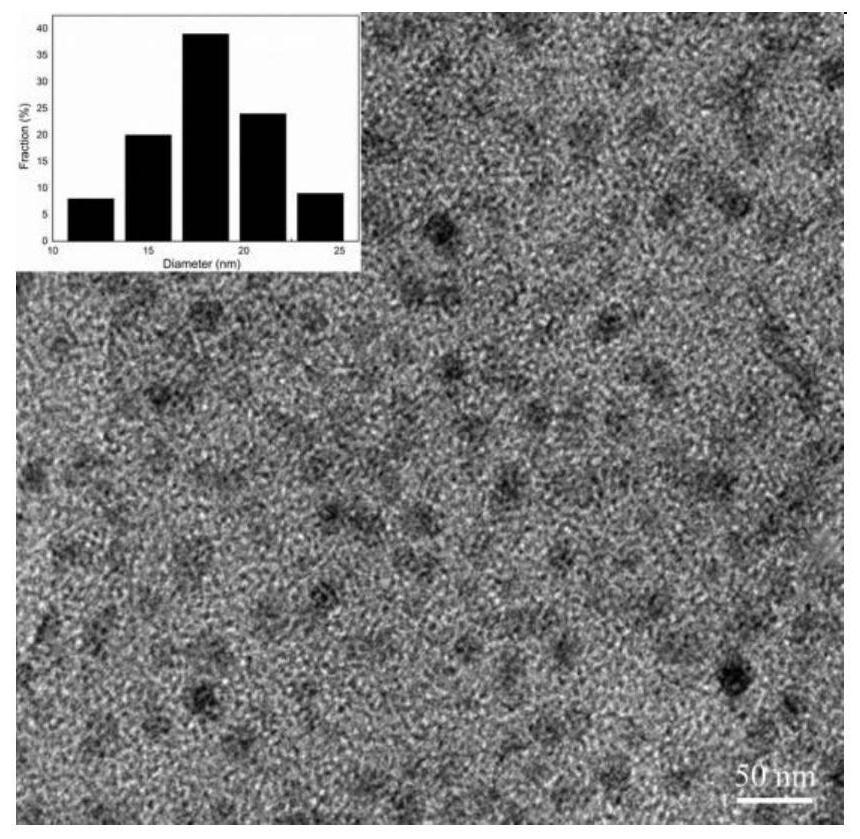

[0024] Take commercially purchased microcrystalline cellulose (MCC) as raw material, weigh 8g, put it into a polytetrafluoroethylene-lined reaction kettle with a volume of 100ml, and put a certain volume of deionized water as a solvent to ensure that the volume of the solution is compared with the volume of the kettle. 8:10, choose nickel acetate as the nickel source for doping, the mass ratio of nickel acetate to microcrystalline cellulose is 2:10, mix well and put the reaction kettle into a box-type incubator, and raise the temperature to the target temperature of 230°C. After constant temperature for 12 hours, cool down to room temperature, filter to obtain a dark brown solid, wash with deionized water, absolute ethanol, and acetone three times respectively, dry and grind. The nickel-doped carbon-based catalyst precursor obtained above was put into a tubular calciner, and under the protection of nitrogen atmosphere, the temperature was raised to 900°C at 5°C / min and kept at ...

Embodiment 2

[0027] Take commercially purchased microcrystalline cellulose (MCC) as raw material, weigh 5g, put it into a polytetrafluoroethylene-lined reactor with a volume of 100ml, and put a certain volume of deionized water as a solvent to ensure that the volume of the solution is proportional to the volume of the kettle. It is 6:10, choose ferroferric oxide as the iron source of doping, the mass ratio of ferroferric oxide and microcrystalline cellulose is 1:4, after mixing evenly, put the reaction kettle into a box-type incubator, and heat up to the target The temperature is 220°C, keep the temperature for 14 hours, cool down to room temperature, filter to obtain a dark brown solid, wash with deionized water, absolute ethanol, and acetone three times respectively, dry and grind. The iron-doped carbon-based catalyst precursor obtained above was put into a tubular calciner, and under the protection of nitrogen atmosphere, the temperature was raised to 950°C at 5°C / min and kept at a const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com