Method for obtaining natural prealbumin from serum

A prealbumin and serum technology, applied in the field of methods and its preparation, can solve the problems of target protein denaturation, complex steps, slow speed, etc., and achieve the effect of optimized removal steps, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method of obtaining natural prealbumin from serum comprising:

[0029] a. Centrifuge the waste human serum to remove fat, take 100ml;

[0030] b. Dilute hydrochloric acid to adjust the serum pH to 4.80;

[0031] c. Add 8ml n-octanoic acid, the Alb protein precipitates;

[0032] d. Centrifuge at 18000r / min at 4°C for 20min at high speed, and filter through a 0.65μm PP membrane to obtain the filtrate;

[0033] e. Adjust the pH value of the filtrate to 4.60, add 9% PEG4000, the PA protein aggregates to form a light blue precipitate, and obtain PA

[0034] f. PA protein is precipitated and reconstituted, then dialyzed to remove impurities and concentrated to make a finished product. The concentration factor is 10 times, and the dialysate contains 10% PEG20000.

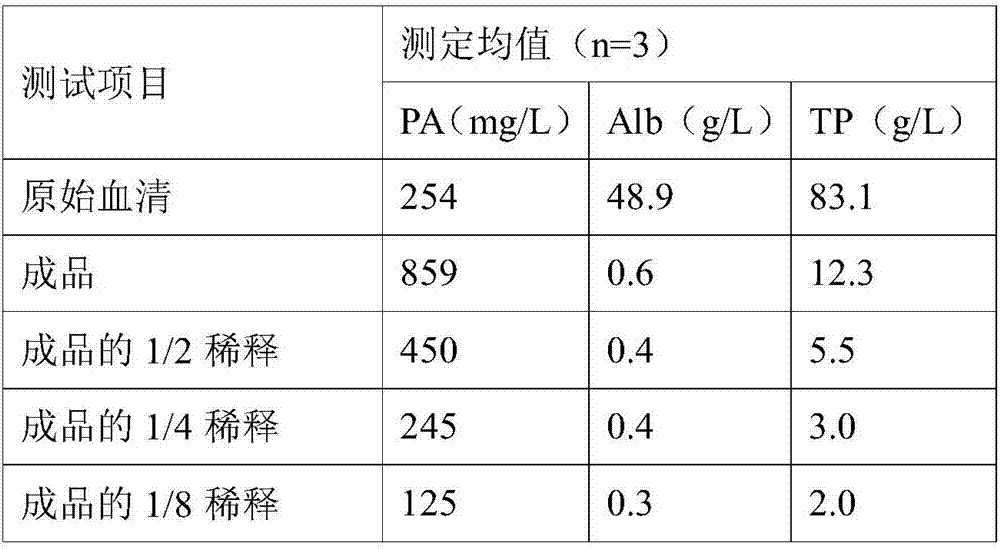

[0035] The contents of PA protein, Alb protein and TP protein in the finished product were determined, and the detection results are shown in Table 1.

[0036] Table 1

[0037]

[0038] It can be seen from...

Embodiment 2

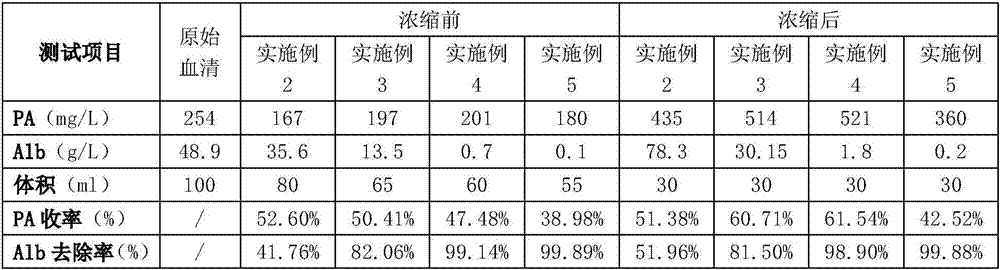

[0040] The difference between this embodiment and embodiment 1 is that the parameters are different in this embodiment, and the specific preparation method of this embodiment is as follows:

[0041] a. Centrifuge the waste human serum to remove fat, take 100ml;

[0042] b. Dilute hydrochloric acid to adjust the serum pH to 4.30;

[0043] c. Add 3ml n-octanoic acid, the Alb protein precipitates;

[0044] d. Centrifuge at 18000r / min at 4°C for 20min at high speed, and filter through a 0.65μm PP membrane to obtain the filtrate;

[0045] e. Adjust the pH value of the filtrate to 4.30, add 3% PEG4000, the PA protein aggregates to form a light blue precipitate, and obtain the PA protein precipitate;

[0046]f. PA protein was precipitated and reconstituted, then dialyzed to remove impurities and concentrated 2.5 times, and the dialysate contained 3% PEG20000.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is that the parameters are different in this embodiment, and the specific preparation method of this embodiment is as follows:

[0049] a. Centrifuge the waste human serum to remove fat, take 100ml;

[0050] b. Dilute hydrochloric acid to adjust the serum pH to 4.60;

[0051] c. Add 5ml n-octanoic acid, the Alb protein precipitates;

[0052] d. Centrifuge at 18000r / min at 4°C for 20min at high speed, and filter through a 0.65μm PP membrane to obtain the filtrate;

[0053] e. Adjust the pH value of the filtrate to 4.40, add 5% PEG4000, the PA protein aggregates to form a light blue precipitate, and obtain the PA protein precipitate;

[0054] f. PA protein was precipitated and reconstituted, then dialyzed to remove impurities and concentrated 2.5 times. The dialysate contained 5% PEG20000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com