Desulfurizing method using three-component eutectic agent to extract

A three-component, deep eutectic technology, applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of poor recycling effect, high mutual solubility of oil products, low desulfurization rate, etc., and achieve low environmental pollution , low cost, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

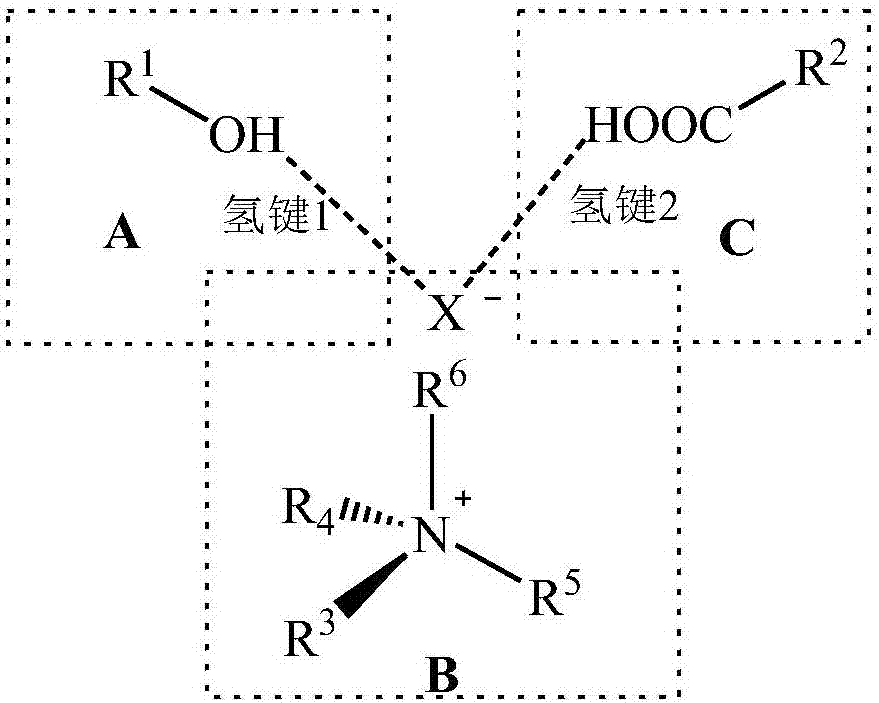

Method used

Image

Examples

Embodiment 1

[0028] Weigh 32.2g (0.10mol) tetrabutylammonium bromide (TBAB), 14.8g n-butanol (n-BA) and 6.3g (0.10mol) concentrated nitric acid (65% HNO 3 ), was added to a 100mL round-bottomed flask, heated and stirred at 90°C for 1h, and a wine-red oily liquid was formed, which was the synthesized low-temperature eutectic solvent [TBAB][n-BA][HNO 3 ].

Embodiment 2

[0030] Weigh 32.2g (0.10mol) tetrabutylammonium bromide (TBAB), 14.8g (0.20mol) n-butanol (n-BA) and 3.6g (0.10mol) concentrated hydrochloric acid (36% HCl), add to 100mL In a round-bottomed flask, heated and stirred at 90°C for 1 h, a bright yellow oily liquid was formed, which was the synthesized low-temperature eutectic solvent [TBAB][n-BA][HCl].

Embodiment 3

[0032]Weigh 32.2g (0.10mol) tetrabutylammonium bromide (TBAB), 14.8g (0.20mol) n-butanol (n-BA) and 13.8g (0.10mol) salicylic acid (OHBA), add to 100mL In a round-bottomed flask, heat and stir at 90°C for 1 h to form a wine-red oily liquid, which is the synthesized low-temperature eutectic solvent [TBAB][n-BA][OHBA].

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap