Apparatus and method for drying clothes

A clothes drying device and cabinet technology, which is applied in the field of wardrobes, can solve the problems of large carbon fiber electric heating plate that cannot be opened separately, uneven distance between carbon fiber electric heating plate and clothes, high cost of controller, etc., and achieves simple structure and high control method Simple and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

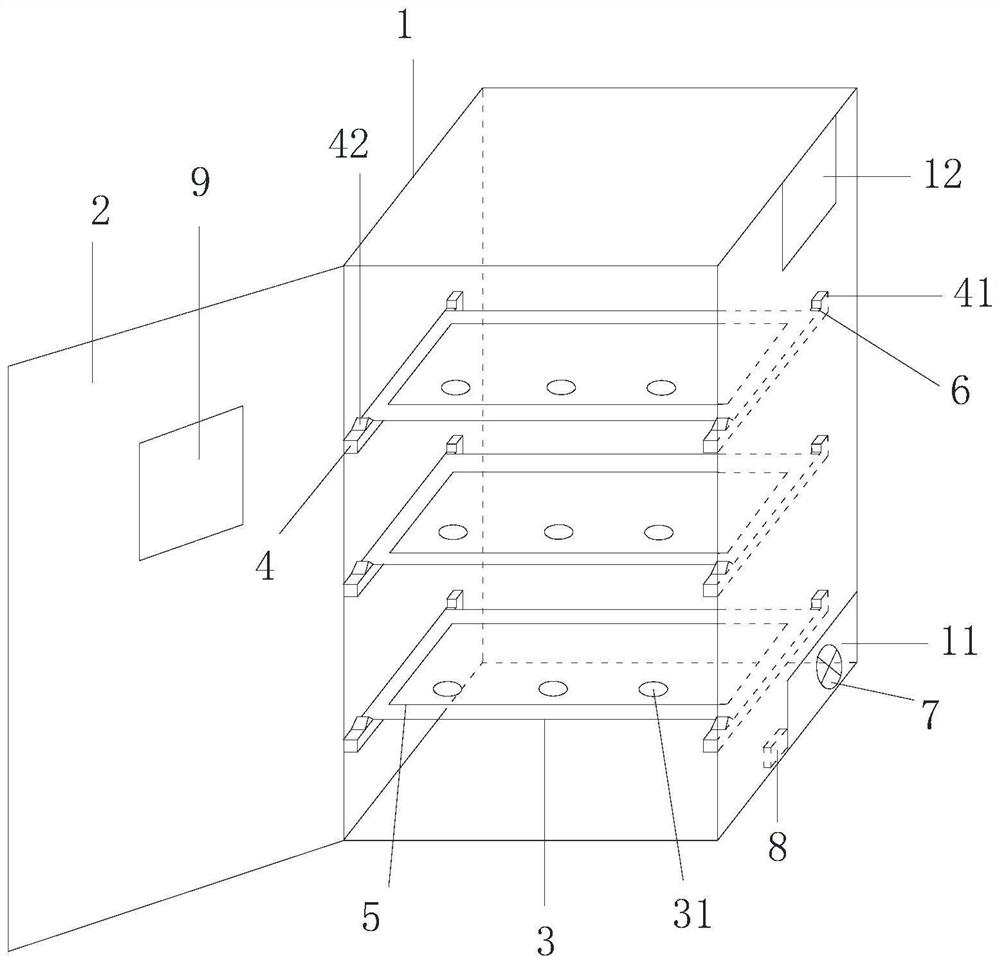

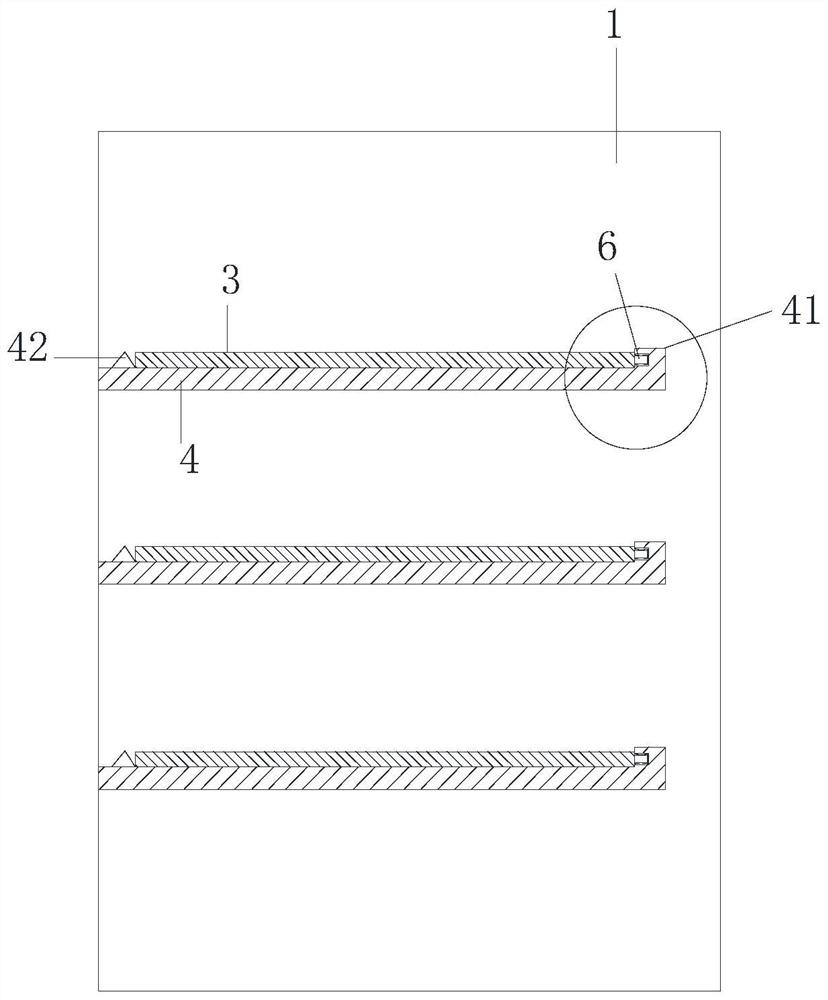

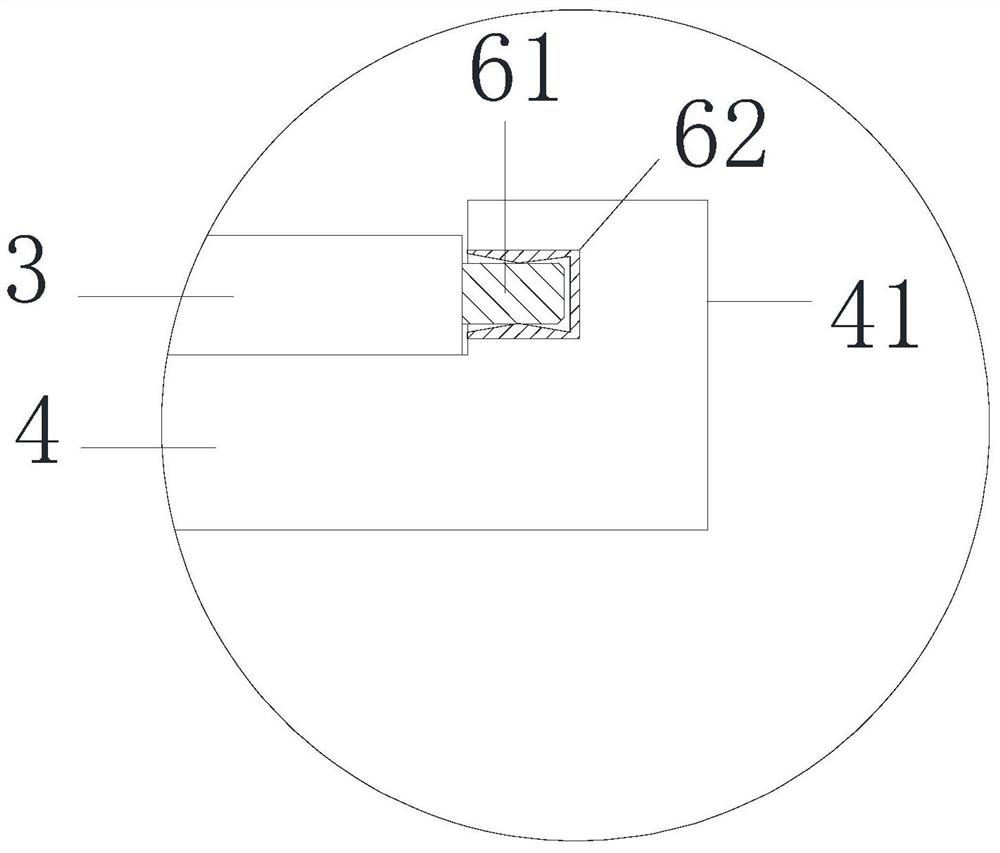

[0042] In the existing drying cabinet, a number of carbon fiber electric heating plates are arranged on the inner wall of the cabinet. The heating plate is an integral structure and cannot be started separately. use. But if you only need to dry a small amount of clothes, all the heating plates will be turned on, which will cause a waste of heat source. At the same time, because the carbon fiber electric heating plate is arranged on the inner wall of the cabinet, the clothes near the inner wall will be heated more, and the clothes in the center will be heated less, resulting in Uneven drying, which is mainly caused by uneven heat radiation due to the unequal distance between the carbon fiber heating plate and the clothes.

[0043] An embodiment of the present invention provides a clothes drying device with a heating plate that can be turned on independently, and the distance between the heating plate and the clothes is equal.

[0044] Such as figure 1 , 2 and Figure 5 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com