Cascade type shaftless electric fan

An electric fan and grid-type technology, which is applied in the field of cascade-type shaftless electric fans, can solve problems such as unreasonable flow channel design, low energy conversion efficiency, and increased flow resistance, so as to achieve safety and not easily hurt people, and improve energy conversion efficiency , the effect of increasing the air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

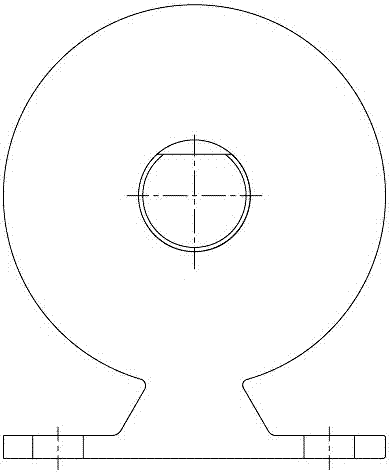

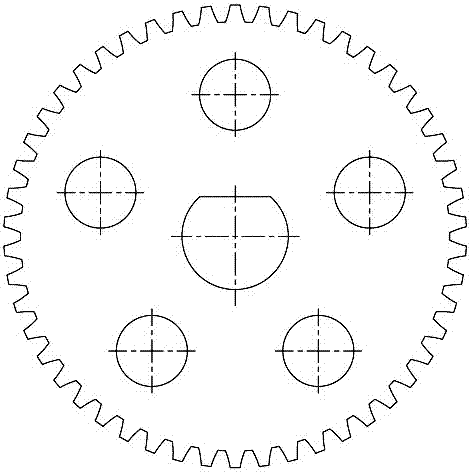

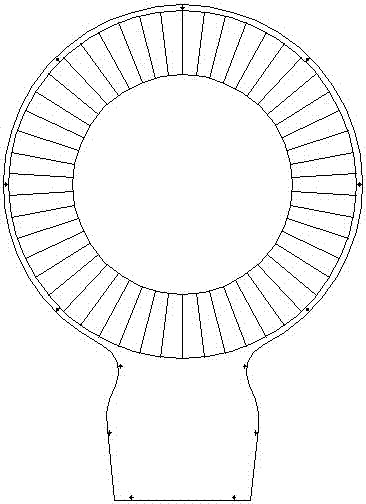

[0023] like Figure 1 to Figure 5 The shown cascade type shaftless electric fan includes a stator part, a rotor part, a rear cover plate 11 and a driving device; the stator part includes a mesh cover 2 and a casing 4, and the casing 4 includes an outer casing arranged in sequence in the radial direction 41. The static cascade 42 and the inner casing 43, the outer casing 41 and the inner casing 43 are all annular structures, and the multiple blades of the static cascade 42 are evenly distributed along the circumferential direction, and the outer casing 41 and the inner casing 43 pass through the static The blades of the cascade 42 are fixedly connected, and the net cover 2 is arranged on the inlet side of the outer casing 41 by screws 1; the rotor part is located in the space formed by the net cover 2 and the casing 4; the rotor part includes a rotating wheel 3 and a gear 8, and the rotating wheel 3 includes an outer ring 31, a moving blade cascade 32 and an inner ring 33 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com