Determination method for permeability of paper-making reconstituted tobacco substrate coating liquid

A technology of reconstituted tobacco leaves and determination methods, which is applied in the field of tobacco analysis, can solve problems such as no public reports, and achieve the effect of accurate measurement results and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

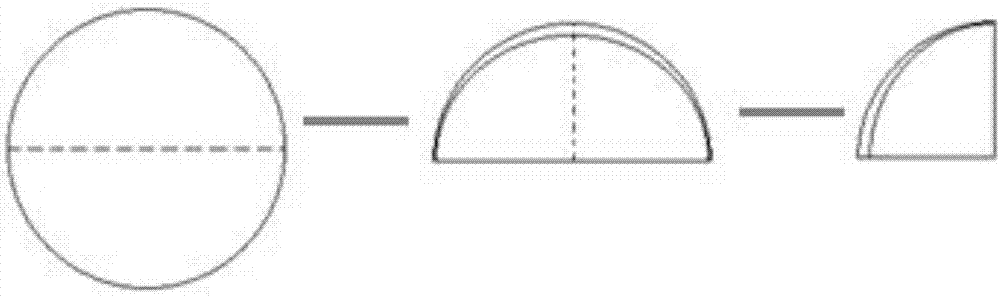

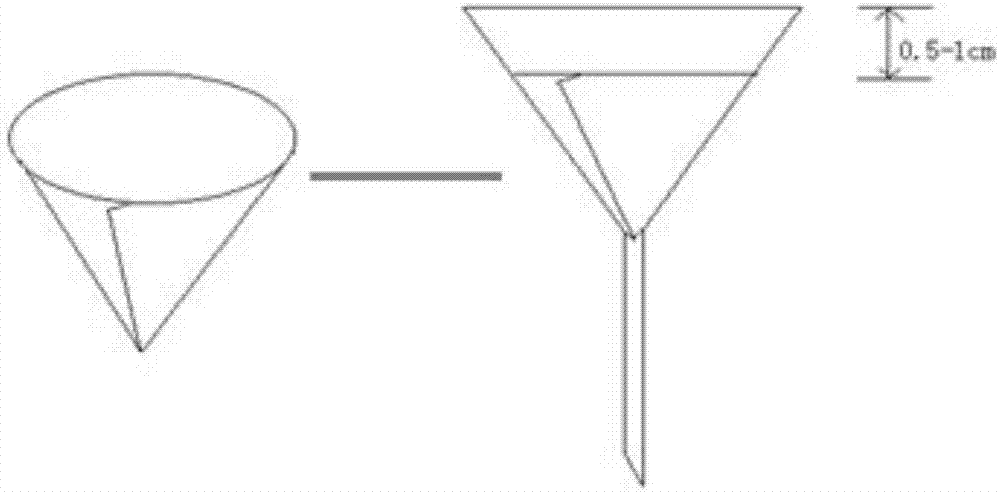

Embodiment 1

[0036] To compare the permeability of paper-making reconstituted tobacco leaf base sheets to the same coating solution produced by different production processes. The samples of reconstituted tobacco leaf substrates of three papermaking methods produced by different beating processes were obtained from the production line. Place the substrate sample in an environment with a temperature of 22°C ± 1°C and a relative humidity of 60% ± 3% for 48 hours to balance its moisture, select the flat and undamaged part of sample 1 and cut it into 6 pieces with a standard quantitative sampler 0.01m 2 of discs. Fold three pieces of cut circular paper with the front side up and three pieces with the back side up, respectively, to form a quarter fan shape, open from the middle to form a cone, put it into a glass funnel, and align the bottom of the glass funnel with the exit Place an Erlenmeyer flask filled with 50ml of clear water, use a pipette to absorb 10ml of the coating solution, use th...

Embodiment 2

[0041] To compare the permeability of different coating liquids in the same papermaking method of reconstituted tobacco leaf substrate. A sample of paper-making reconstituted tobacco leaf base sheet and three coating solutions with different formulations were obtained from the production line. The substrate sample is placed in an environment with a temperature of 22°C ± 1°C and a relative humidity of 60% ± 3% for 48 hours to balance its moisture. Select the flat and undamaged part of the sample and use a standard quantitative sampler to cut it into 6 sheets with an area of 0.01m 2of discs. Fold three pieces of cut circular paper with the front side up and three pieces with the back side up, respectively, to form a quarter fan shape, open from the middle to form a cone, put it into a glass funnel, and align the bottom of the glass funnel with the exit Place an Erlenmeyer flask filled with 50ml of clear water, use a pipette to absorb 10ml of the coating liquid sample 1, quickl...

Embodiment 3

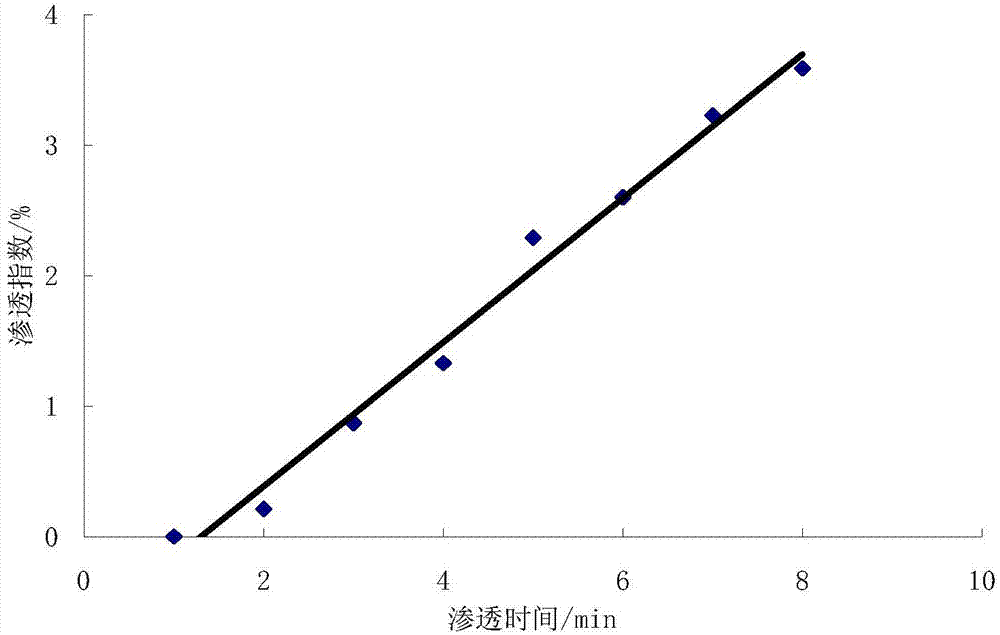

[0046] Detecting the dynamic process of coating liquid penetration in papermaking reconstituted tobacco leaf substrates. Samples of reconstituted tobacco leaf substrates and coating liquid samples obtained from the production line. The substrate sample is placed in an environment with a temperature of 22°C ± 1°C and a relative humidity of 60% ± 3% for 48 hours to balance its moisture. Select the flat and undamaged part of the sample and use a standard quantitative sampler to cut it into 4 sheets with an area of 0.01m 2 of discs. Fold three pieces of cut circular paper with the front side up and three pieces with the back side up, respectively, to form a quarter fan shape, open from the middle to form a cone, put it into a glass funnel, and align the bottom of the glass funnel with the exit Place an Erlenmeyer flask filled with 50ml of clear water, use a pipette to absorb 10ml of the coating liquid sample 1, quickly transfer all the coating liquid in the pipette into the funn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com