Numerical simulation method for silicon carbide ceramic ordinary pressure solid phase sintering process

A silicon carbide ceramic, solid-phase sintering technology, applied in CAD numerical modeling, design optimization/simulation, electrical digital data processing, etc. The problems of deformation and temperature distribution of ceramic products can save material and labor costs, improve preparation level, improve yield and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

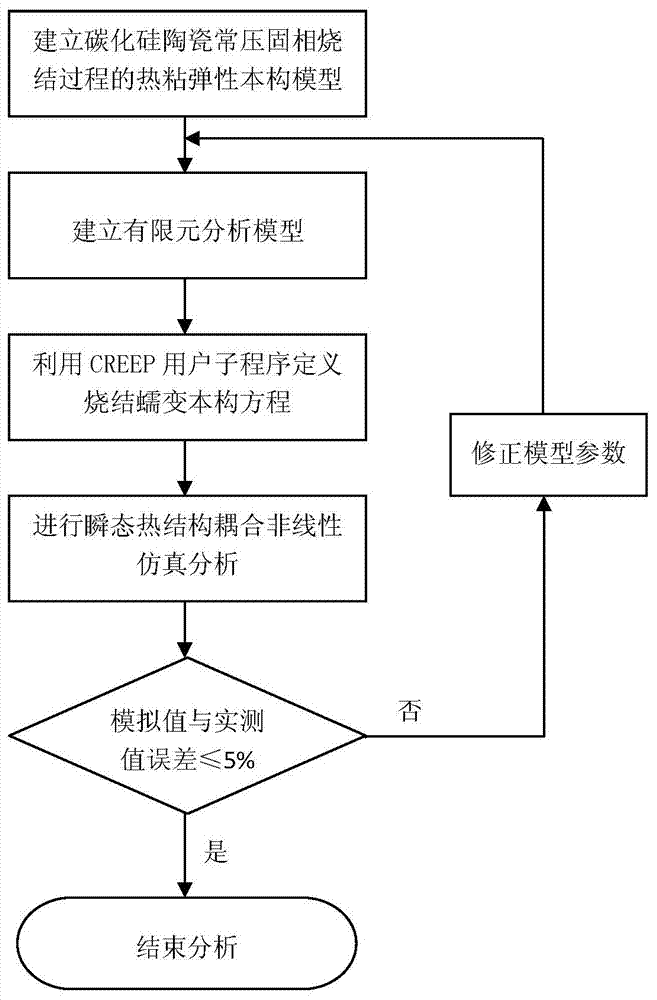

[0067] Aiming at the defect that the current traditional normal-pressure solid-phase sintering process of silicon carbide ceramics can only formulate a sintering plan based on experience, but cannot predict the sintering quality and evaluate the process parameters before sintering, the present invention proposes an atmospheric-pressure solid-phase sintering process for silicon carbide ceramics. A numerical simulation method for phase sintering process, including the following steps:

[0068] Step 1: Establish a thermo-viscoelastic constitutive model for the normal-pressure solid-phase sintering process of silicon carbide ceramics;

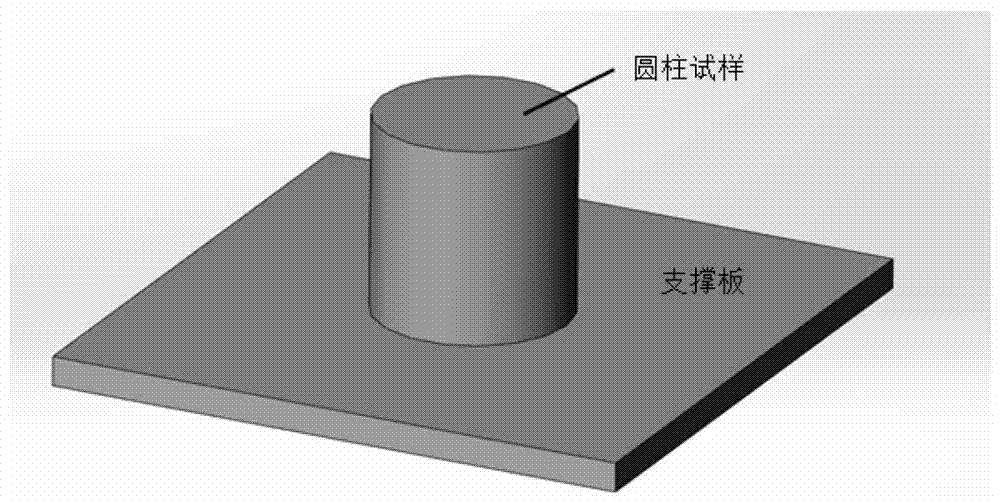

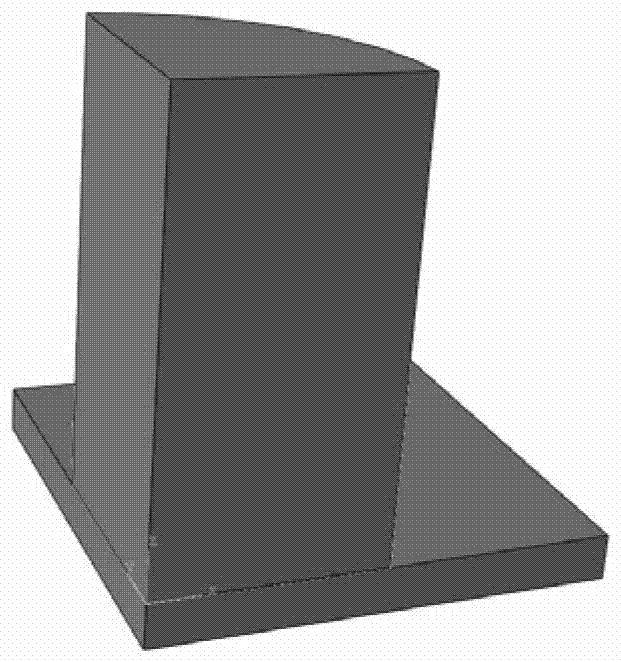

[0069] Step 2: Establish the finite element analysis model, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com